Silos Battery Belt Conveyor Optimal Feed Rate

Bulk solids handlingEngineering Feeder and Conveyor Design

Technically, a conveyor does not feed or control the transfer rate. A feeder must be designed so that it is an integral part of the hopper, the feeder supplements the forces of

Belt Conveyors Grain Systems

根据热度为您推荐•反馈

Types of Screw Feeders Engineering Guide

UsageConstructionDesignEquipmentPerformanceFunctionAssessmentOperationAdvantagesSafety

Most screw feeder speeds are lower than standard screw conveyor speeds. For example, in heavy industrial applications, screw feeders typically operate at speeds less than 20-RPM. More torque is generated at lower operating speeds ensuring the screw feeder does not stall at start-up.

Conveyors / Belt Feeders

High capacity 16" wide belt conveys any type of forage, ground feed or TMR at high speed and low horsepower up to 180 feet. Smooth belts are available for up to 15 degree inclines. Textured belts are available for up

Belt conveyor Silos Córdoba

Made of S350GD galvanized steel sheet with Z-600 metal coating, TBI Belt Conveyor can operate efficiently with a wide range of grains, seeds, legumes and pellets. Different equipment and configurations allow to

Enclosed belt conveyors Silos Córdoba

The TBC Enclosed Belt Conveyor developed by Silos Córdoba. has been designed for non-stop daily use throughout the year. Made of hot galvanized welded plate, the TBC Enclosed Belt Conveyor can operate efficiently

silos battery mineral ball mill optimal feed rate github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Silos Battery Belt Lift Optimal Feed Rate Beltconveyers Net

Dec 24, 2012 0183 32 silos battery belt conveyor optimal feed rate,SandCat for optimal,conveyor belt,scraper system inclined feed conveyor,TAIYU4 battery belt conveyor

Optimal scheduling method for belt conveyor system in

2020年10月1日Through the coordination of belt speed and feed rate, the full load operation status of the BC can be realized. Besides the energy savings, less mechanical

Optimal scheduling method for belt conveyor system in coal

2020年10月1日Through coordinated control of belt speed, feed rate, silo load rate and arrival time of the train, the virtual energy storage ability of silo is utilized to realize the power balance considering distributed generations in different period in response to the time-varying electricity price.

Optimal scheduling method for belt conveyor system in coal

2020年10月1日The case study indicates that the optimal scheduling method in this stone can effectively reduce the electricity cost of the belt conveyor by 61.29%, and improve the power consumption level of the

Optimal scheduling method for belt conveyor system in coal

Through coordinated control of belt speed, feed rate, silo load rate and arrival time of the train, the virtual energy storage ability of silo is utilized to realize the power balance considering distributed generations in different period in response to the time-varying electricity price.

Bulk solids handlingEngineering Feeder and Conveyor Design

Screw conveyors and feeders rely on friction to move the product along a static enclosure. A spiral rotates at a particular speed, to maintain a fill level typically around a maximum of 45% volumetric capacity to prevent product flow back in a “U” trough casing construction.

Belt Conveyors Grain Systems

In addition to grain and feed markets, InterSystems, the brand known as a worldwide manufacturer of bulk material handling equipment and industrial sampling systems, is found on a full range of products in support of other

Types of Screw Feeders Engineering Guide

The speed of the screw feeder can be determined by dividing the maximum screw feeder capacity in cubic feet per hour by the capacity of the Control Pitch in cubic feet per hour per RPM. Most screw feeder speeds are

Conveyors / Belt Feeders

High capacity 16" wide belt conveys any type of forage, ground feed or TMR at high speed and low horsepower up to 180 feet. Smooth belts are available for up to 15 degree inclines. Textured belts are available for up

Silos and Auger for poultry SKA Poultry Equipment

Silos and Auger. Equipment often sold together, complementary to each other. A wide range of silos and augers is available. The main distinction between the models is the flow rate and capacity, the systems are

silos battery mineral ball mill optimal feed rate github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

conveyor feed rate calculations

Belt Conveyor mpl delivers the world’s most comprehensive range of Heavy-duty conveyor belts. Base on more than 30 years of experience in development, manufacture and applications know-how, mpl designed the unique belts and belt systems to meet specific end-user requirements for high performance and cost-efficiency.

Silos Battery Belt Lift Optimal Feed Rate Beltconveyers Net

Dec 24, 2012 0183 32 silos battery belt conveyor optimal feed rate,SandCat for optimal,conveyor belt,scraper system inclined feed conveyor,TAIYU4 battery belt conveyor system to cement silo Know MoreThe Bath Lift Belt is powered by a rechargeable battery eliminating electrical connection to the mains when in use making

Airslide conveying technology

• Fluidized silo bottom. Generally, materials passing through 35 mesh US std. (500 microns) can be conveyed through an Airslide ® conveyor. From Silo. Typical isolation . Enlarged detail and flow control . valve arrangement Drum . roller. ’s Airlift ™ vertical conveyors and Airslide ® gravity conveying systems convey

Optimal and energy efficient operation of conveyor belt systems

2016年7月8日Downhill conveyors are important potential energy sources within conveyor belt systems (CBSs). Their energy can be captured using regenerative drives. This stone presents a generic optimisation model for the energy management of CBSs that have downhill conveyors. The optimisation model is able to optimally schedule three

Screw ConveyorsFeeders Bucket Elevators Manufacturer

Screw ConveyorsFeeders Bucket Elevators Manufacturer Bulk

Optimal scheduling method for belt conveyor system in coal

2020年10月1日An optimal scheduling model of belt conveyor integrated with virtual energy storage was developed. Through coordinated control of belt speed, feed rate, silo load rate and arrival time of the train, the virtual energy storage ability of silo is utilized to realize the power balance considering distributed generations in different period in

Optimal scheduling method for belt conveyor system in coal

2020年10月1日The case study indicates that the optimal scheduling method in this stone can effectively reduce the electricity cost of the belt conveyor by 61.29%, and improve the power consumption level of the

Optimal scheduling method for belt conveyor system in coal

Through coordinated control of belt speed, feed rate, silo load rate and arrival time of the train, the virtual energy storage ability of silo is utilized to realize the power balance considering distributed generations in different period in response to the time-varying electricity price. "Optimal scheduling method for belt conveyor system

Optimal and energy efficient operation of conveyor belt systems

2016年7月8日Downhill conveyors are important potential energy sources within conveyor belt systems (CBSs). Their energy can be captured using regenerative drives. This stone presents a generic optimisation model for the energy management of CBSs that have downhill conveyors. The optimisation model is able to optimally schedule three

Bulk solids handlingEngineering Feeder and Conveyor Design

Technically, a conveyor does not feed or control the transfer rate. A feeder must be designed so that it is an integral part of the hopper, the feeder supplements the forces of gravity as in silo design, and does not impose additional consolidation pressures into the product this is of utmost importance when handling cohesive, high moisture

Belt Conveyors Grain Systems

In addition to grain and feed markets, InterSystems, the brand known as a worldwide manufacturer of bulk material handling equipment and industrial sampling systems, is found on a full range of products in support of other industries. Belt Conveyors High Quality and Highly Efficient. GSI has the perfect belt conveyor to fit your operation

Construction and Maintenance of Belt Conveyors for Coal and

Construction and Maintenance of Belt Conveyors for Coal and Bulk

Silos and Auger for poultry SKA Poultry Equipment

Silos and Auger. Equipment often sold together, complementary to each other. A wide range of silos and augers is available. The main distinction between the models is the flow rate and capacity, the systems are supplied suitably sized according to the needs of each farm. The many accessories allow responding to various needs and making them

conveyor feed rate calculations

Belt Conveyor. mpl delivers the world’s most comprehensive range of Heavy-duty conveyor belts. Base on more than 30 years of experience in development, manufacture and applications know-how, mpl designed the unique belts and belt systems to meet specific end-user requirements for high performance and cost-efficiency.

Silos Battery Belt Lift Optimal Feed Rate Beltconveyers Net

Dec 24, 2012 0183 32 silos battery belt conveyor optimal feed rate,SandCat for optimal,conveyor belt,scraper system inclined feed conveyor,TAIYU4 battery belt conveyor system to cement silo Know MoreThe Bath Lift Belt is powered by a rechargeable battery eliminating electrical connection to the mains when in use making

Screw ConveyorsFeeders Bucket Elevators Manufacturer

Screw ConveyorsFeeders Bucket Elevators Manufacturer Bulk

Airslide conveying technology

• Fluidized silo bottom. Generally, materials passing through 35 mesh US std. (500 microns) can be conveyed through an Airslide ® conveyor. From Silo. Typical isolation . Enlarged detail and flow control . valve arrangement Drum . roller. ’s Airlift ™ vertical conveyors and Airslide ® gravity conveying systems convey

- 2014 Hot Selling Min Mobile Crushing Plant

- 某工程队要运进1吨石子

- 选矿生产线基本介绍

- 供应氧化铁染料红黄黑绿

- 选矿机械动态图

- 风扫磨煤机用途

- Continental Trapezoid Mill How To Make Minning Equipment

- 投资一个机柜生产厂需要多少钱

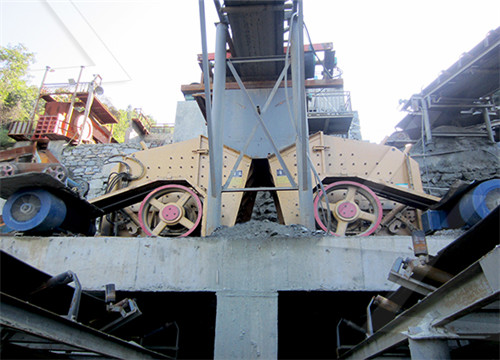

- Double Roll Crusher Specification

- 台湾七彩石头

- Mill Production Line For Granite Maluku?Indonesia

- 混凝土粉碎打砖机

- Double Toggle Jaw Crusher Design Double Toggle Jaw Crusher Desig

- 商业混凝土生产线

- 矿粉工艺考核制度