Double Toggle Jaw Crusher Design Double Toggle Jaw Crusher Desig

Jaw Crusher ScienceDirect

2016年1月1日Double-Toggle Jaw Crusher. Figure 4.2 is a sketch of a Dodge type of crusher. They are comparatively lower in capacity than the Blake crushers and are

D42 Double Toggle Jaw Crusher Jaques

Jaw Crusher The ® Jaques Double Toggle jaw crushers feature large gape feed openings, high production and low operating costs. These rugged machines are

Crushers QueensMineDesignWiki

IntroductionLocation of The Crusher in An Underground MineMaterial HandlingTechnology and Equipment SelectionCostingDust ControlConclusions and RecommendationsReferences

Operating CostsThe primary operating costs of a crusher are parts and labour for maintenance, which can vary approximately twice as much as the power for the motor. Gyratory crushers generally cost less than $1500 per hour to run, while Jaw crushers cost less than $200, including electricity (Infomi在minewiki.engineering.queensu.ca上查看更多信息

Difference Between SingleDouble Toggle Jaw Crusher

2014年9月20日Double Toggle Jaw Crusher In contrast, the single toggle jaw crusher has fewer shafts and bearings and only one toggle

Optimization Design for Crushing Mechanism of

This stone conducts a comprehensive study on the optimization design for crushing mechanism of double toggle jaw crusher. The optimization aim is to reduce characteristic value of moving jaw plate, to raise capacity of

Blake Jaw Crusher Mineral ProcessingMetallurgy

2016年1月15日Double-toggle crusher The Blake Jaw crusher frames have been the subject of considerable variety in details of design and have been built of several different materials. Originally all frames were of cast

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日The plate warping reduces the crusher performance, resulting in low crusher efficiency, high cost of replacing the crushing plates, and higher energy consumption. Moreover, the wear of the...

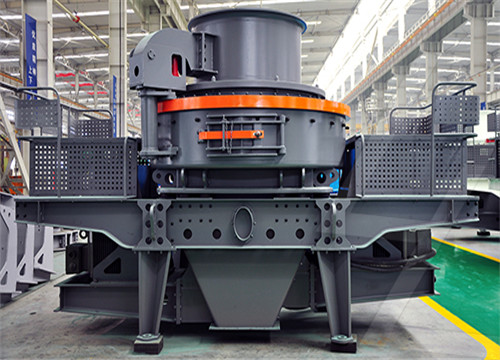

Double Toggle Jaw Crusher Premur Impex the robust power of

Application. Primary and Secondary Crushing of Hard rocks, ores and Minerals including Lime Stone, Dolomite, Granite, Iron Ore, Chromite Ore, Ferro-alloy slag etc., with a

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more

TST jaw crusher

Jaw crushers 2 ’s history with the design and manufacture of jaw crushers dates back more than 100 years with the Traylor and Fuller-Traylor double toggle jaw crushers. These crushers have continuously withstood the harshest duties found in the world.

Jaw Crusher ScienceDirect

2016年1月1日Double-Toggle Jaw Crusher. Figure 4.2 is a sketch of a Dodge type of crusher. They are comparatively lower in capacity than the Blake crushers and are more commonly used in laboratories. Download : Download full

D48 Double Toggle Jaw Crusher Jaques

The ® Jaques Double Toggle jaw crushers feature large gape feed openings, high production and low operating costs. These rugged machines are manufactured with heavy duty parts for constant operation and long life. Our double-toggle jaw crushers suitable for hard and very hard rocks and abrasive applications Contact Us Sign Up Find a Dealer

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

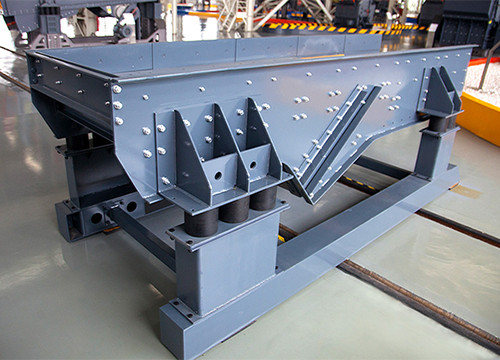

Diagram of a double-toggle jaw crusher [image: (135-5-7)] The dimensions defined by those particle sizes are: Gape: The distance between the jaws at the feed opening Closed side set (CSS): The minimum opening between the jaws during the crushing cycle (minimum discharge aperture) Open side set (OSS): The maximum discharge aperture

Optimization Design for Crushing Mechanism of Double Toggle Jaw Crusher

This stone conducts a comprehensive study on the optimization design for crushing mechanism of double toggle jaw crusher. The optimization aim is to reduce characteristic value of moving jaw plate, to raise capacity of jaw crusher, and to ensure entrance and outlet dimensions of jaw crusher. Firstly, formulae are derived for displacement of the

Analysis of the Single Toggle Jaw Crusher Force Transmission Hindawi

The motion of the swing jaw in a double toggle crusher is such that it applies an almost purely compressive force upon the material being crushed. This minimizes wear on the crushing surfaces of the jaws and makes the double toggle jaw crusher suitable for crushing highly abrasive and very hard materials.

Primary Crusher SelectionDesign Mineral Processing

2015年12月23日There are exceptions like MPI Mineral Park in AZ where 50,000 TPD was processed via 2 early century vintage jaw crushers of a: Traylor –Fuller Size:–56” x 72” Type: H; Toggle Type Double; HP:–400; Minimum Jaw Gap : 6” + Birdsboro Size:–56” x 72” Type-C; Double Toggle Type; 400 HP; both with Amsco as the liner supplier.

Building a Double Toggle Jaw Crusher Crushing, ScreeningConveying

Jaw plate wear has considerable affect on the life of jaw Crusher which is caused by the slipping motion between the fed material and the jaws. This wear is predominantly serious in the fixed plate and hence the liners of the fixed jaw should be properly chosen. In addition to this the toggle bar which acts as a safety lever has to be precisely

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more compact design than

The kinematics and mechanical advantage of the double-toggle jaw crusher

2017年10月19日Dimensional data of a typical double-toggle jaw crusher are used in the derived mathematical expressions to demonstrate their application. Moreover, starting with the equation for the angular velocity ratio of the moveable jaw, with respect to the input crank, an expression for the ideal mechanical advantage of the crusher is derived.

[PDF] Dynamic Analysis of Double Toggle Jaw Crusher Using Pro

Pro/Engineer is a parametric feature-based design of 3D software and capable to solve the motion dynamics of the motion, and the reactions at the constraints of the mechanisms can be used as the inputs for any Finite element program to understand the behaviour of stresses and deformations of the individual component of the machine to estimate the

Double toggle (blake) jaw crusher GrabCAD

2019年8月27日Double toggle (blake) jaw crusher. Tamas Cserto. August 27th, 2019. Double toggle jaw crusher educational project. Based on (Hungarian) GANZ Double toggle jaw crusher (about 1950). This model is made into a technical textbook. Download files. 1002 Downloads 87 Likes 6 Comments.

Used double toggle jaw crusher Machinio

Kobelco 54" X 74" Blake Type Jaw Crusher, double toggle design, Model 90C-DH, Serial number 112934. Previously used with 300 HP, 1,200 RPM motor (currently less motor). Double Toggle Jaw Crusher. Special Feature: Drive Mechanism Inspection Slot. Gross weight 21,200 KGS. Feed Size: 1065 x 815 mm. Transport Dimensions: 3500 x 2060 x

Crushers an overview ScienceDirect Topics

Figure 8.1 shows two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates.

D48 Double Toggle Jaw Crusher Jaques

The ® Jaques Double Toggle jaw crushers feature large gape feed openings, high production and low operating costs. These rugged machines are manufactured with heavy duty parts for constant operation and long life. Our double-toggle jaw crushers suitable for hard and very hard rocks and abrasive applications Contact Us Sign Up Find a Dealer

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Diagram of a double-toggle jaw crusher [image: (135-5-7)] The dimensions defined by those particle sizes are: Gape: The distance between the jaws at the feed opening Closed side set (CSS): The minimum opening between the jaws during the crushing cycle (minimum discharge aperture) Open side set (OSS): The maximum discharge aperture

[PDF] Dynamic Analysis of Double Toggle Jaw Crusher Using Pro

Pro/Engineer is a parametric feature-based design of 3D software and capable to solve the motion dynamics of the motion, and the reactions at the constraints of the mechanisms can be used as the inputs for any Finite element program to understand the behaviour of stresses and deformations of the individual component of the machine to estimate the

Optimization Design for Crushing Mechanism of Double Toggle Jaw Crusher

This stone conducts a comprehensive study on the optimization design for crushing mechanism of double toggle jaw crusher. The optimization aim is to reduce characteristic value of moving jaw plate, to raise capacity of jaw crusher, and to ensure entrance and outlet dimensions of jaw crusher. Firstly, formulae are derived for displacement of the

Primary Crusher SelectionDesign Mineral Processing

2015年12月23日Double Toggle Type 400 HP both with Amsco as the liner supplier. The rated capacity at 5” closed-side setting was 490 stph based on standard 100lbs/ft3 feed material. These crushers were fed a very fine ore over a 4″ grizzly which allowed the 1000 TPH the SAG mills needed.

Double toggle (blake) jaw crusher GrabCAD

2019年8月27日Double toggle (blake) jaw crusher. Tamas Cserto. August 27th, 2019. Double toggle jaw crusher educational project. Based on (Hungarian) GANZ Double toggle jaw crusher (about 1950). This model is made into a technical textbook. Download files. 1002 Downloads 87 Likes 6 Comments.

Used double toggle jaw crusher Machinio

Jaw crusher, 36" x 42" jaw s, manufactured by Traylor, Type HB, double toggle, driven by 125 HP motor, 5" closed side, crusher stroke, swing jaw 1". Includes automatic lube system. State College, PA, USA Click to Request Price Trusted Seller PENNSYLVANIA DT20x36 USED Manufacturer: PENNSYLVANIA Pennsylvania DT 20x36 Jaw Crusher.

Building a Double Toggle Jaw Crusher Crushing, ScreeningConveying

Our double toggle jaw crusher cannot crush properly and we are obligated to feed it with finer material (limestone). We noticed that the mobile jaw barely moves to crush the material. What is wrong and how can we repair this problem. Please join and login to participate and leave a comment.

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more compact design than

Double Toggle Oil Type Jaw Crusher Equipments| Double Toggle

Double Toggle Oil Type Jaw Crusher. Oil type jaw crushers are configured for primarysecondary crushing of even hardest rock at hardest speed with minimum power. The crusher is designed on principal of crushing without rubbing, with high impact pressure. Pitman is always in compression condition, having unique design filled with metal

Characteristics and Comparison of Four Types of Jaw Crushers

2023年2月15日The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding part. Double toggle jaw crusher Also, swing jaw is

The kinematics and mechanical advantage of the double-toggle jaw crusher

2017年10月19日The expressions derived in this stone provide the foundation for further investigations into the mechanics and the design of the double-toggle jaw crusher. Discover the world's research 20

Crushers an overview ScienceDirect Topics

A double toggle crusher has, basically, two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates. The moving jaw has a pure reciprocating motion toward the fixed jaw.

100mm MPE Sealed Compact Jaw Crusher Double Toggle For

China 100mm MPE Sealed Compact Jaw Crusher Double Toggle For Laboratory, Find details about China Laboratory Rock Crusher from 100mm MPE Sealed Compact Jaw Crusher Double Toggle For Laboratory Y&X Beijing Technology Co., Ltd..