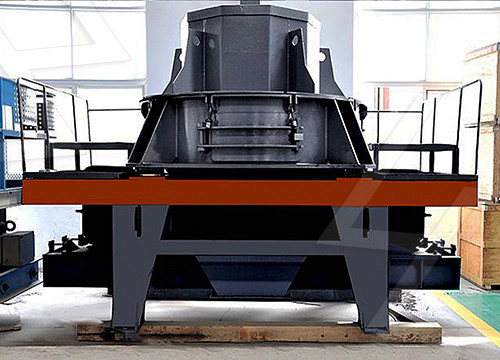

Double Roll Crusher Specification

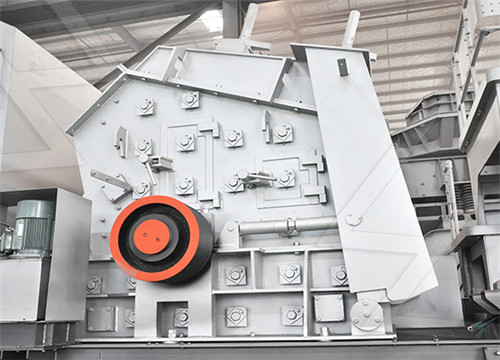

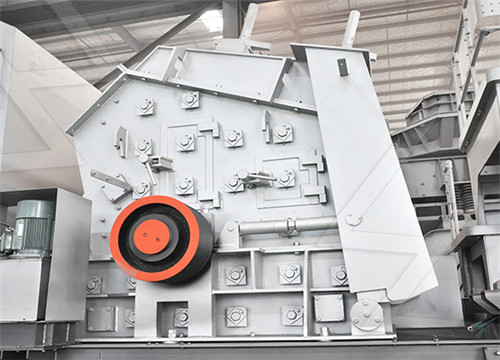

Double Roll Crushers McLanahan

Double Roll Crushers are one of the most widely used crushers in the mining industry and have numerous advantages, such as high capacity, low headroom, low horsepower, the ability to handle wet, sticky feeds and

Roll Crushers McLanahan

Double Roll Crushers provide a 4:1 reduction ratio. They are typically used as a secondary or tertiary crusher for materials such as ROM coal with refuse, limestone, gypsum,

Double-Roll-Crusher thyssenkrupp-polysius

Double-Roll-Crushers are used for the crushing or medium-hard rock as well as for sticky and soft materials, i.e. clay, marl, limestone and similar raw materials. Sticky and soft

Double Roll Crushers Astec

Used as a primary or secondary unit, double roll crushers can be used in nearly any application with even the hardest, most abrasive material. This efficient crusher can

Double Roll Crusher, 13mm Particle Size Gilson Co.

Double Roll Crushers are designed for single-pass size reduction of medium-hard to hard materials such as rock or ore to a nominal minus 10 mesh. Topsize is approximately 13mm and final fineness typically

Roll Crushers TAKRAF TAKRAF GmbH

We design, fabricate and supply roll crushers for capacities ranging up to 14,000 t/h for material with a compressive strength of up to 200 MPa Safety Double overload

Roll Crushers Gundlach Crusher Brand TerraSource Global

Gundlach roll crushers are available in four model series with single-stage and two-stage designs and produce precise product sizing with fewer fines. Watch Roll Crusher Animation See the full range of Gundlach Crusher

Double Roll Crushers Moore Watson Ltd

The DRC series roller crusher is widely used in tertiary crushing with the material feeding size less than 30mm and the product size 1 10mm of artificial sand making

Double Roll Crusher Brochure McLanahan

Double Roll Crusher Brochure. Typically used as secondary or tertiary crushers, McLanahan Double Roll Crushers provide a 4:1 reduction ratio and can be used following other McLanahan equipment, such as Feeder

Roll Crusher ManufacturerDesign Williams Crusher

Roll crushing surfaces operate at a fixed distance apart, as opposed to the continually changing distances in a jaw or cone crusher. This creates a more consistent product size. Roll crushers are low in profile and

Double-Roll-Crusher thyssenkrupp-polysius

Double-Roll-Crushers are used for the crushing or medium-hard rock as well as for sticky and soft materials, i.e. clay, marl, limestone and similar raw materials. Sticky and soft materials are reliably crushed in 2 or 3 stages down to the required product size. Due to the low crushing ration, the thyssenkrupp Double-Roll-Crusher is producing a

Double Roll Crushers Astec

Used as a primary or secondary unit, double roll crushers can be used in nearly any application with even the hardest, most abrasive material. This efficient crusher can lower power requirements for producing material and, with its unique features, can increase machine life. Features Release Mechanism

Design, Fabrication and Testing of a Double Roll Crusher

2.1.5 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], The specification for is 120mm, width, W, of each roll is

Double Roll Crusher Fodamon Machinery

Double roll crusher is mainly used for the crushing of medium or lower-hardness mines and rocks with medium or lower rigidity in mine selection, chemicals, cement and building materials industrial production. Roll

Double Roller Crusher-Baichy Machinery

Double roller crusher is mainly used for secondary and fine crushing materials with soft or middle hardness like coal, coke, limestone, clinker mineral, slag, shale and so on. Depending on the requirements, the rolls are smooth or toothed. ≤100mm Feed Size 11-90KW Motor Power 10-85 t/h Processing capacity Get Quotes Leave Message 60S

EXTEC Double Roll Crusher SpecificationsTechnical Data (2004

EXTEC Double Roll Crusher SpecificationsTechnical Data (2004-2008) Rate this machine now! Operating weight: 46t Transport length: 14.0m Transport width: 2.8m Transport height: 3.3m Plant type: RM Drive: D/Hy Technical specs BuyRent PartsComponents EventsNews Transport ContactsHelp Technical specs Double Roll

200-450 TPH Rock Double Roller Crusher High Yield

China 200-450 TPH Rock Double Roller Crusher High Yield Environmental Friendly, Find details about China Double Roller Crusher from 200-450 TPH Rock Double Roller Crusher High Yield Environmental Friendly Sichuan BENO Energy Conservation and Environmental Protection Technology Co., Ltd..

Tooth double coal roll crusher design images roller crusher of

INQUIRY ABOUT Tooth double coal roll crusher design Fote Heavy Machinery Co., ltd. Price : $2000 $20000 / Set; Min.order : 1 Sets; Brand Name : Fote heavy machinery;

Double Roller Crusher with Simple Structure and Reliable

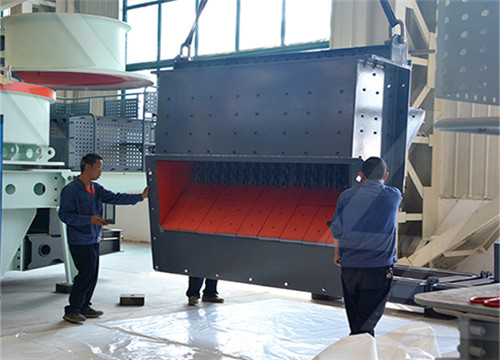

Mainly consists of housing, rolls and deep tooth gear; Safety spring also has double motors and belts to drive; V-belt drives 2 rolls to rotate in opposite direction by motors and finish material crushing; Space of rolls can be adjusted within certain range to control discharging size; Smallest discharge granularity could be <100 meshes

Double Roll Crusher 911Metallurgist

For sale with its 8 inch by 3 inch rolls, the 911MPERC8C is the finest laboratory double roll crusher China has. It is massive and of top quality! Crushing by the Double-Roll Crusher is primarily accomplished by compression and consist of two heavy metal rolls of equal diameter placed horizontally which are rotated towards each other at same or at different

Products

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material. For the industrial beneficiation of raw materials, energy-efficient roll crushers, with high throughput rates, are becoming increasingly important from an economic

Steele Smooth Roll Crushers Steele Machinery J.C. SteeleSons

Output size As low as 1/16” (1.6mm), with a practical minimum roll spacing of 1/8” (3.2mm) Throughput Up to 70 tons per hour with a 1/8” (3.2mm) gap, depending on feed material Industry Applications Intermediate smashing and flattening for clay working applications in brick, block and tile Smashing coal fines, coke breeze or gypsum waste

Double Roll Crusher Brochure McLanahan

Double Roll Crusher Brochure. Typically used as secondary or tertiary crushers, McLanahan Double Roll Crushers provide a 4:1 reduction ratio and can be used following other McLanahan equipment, such as Feeder

Double-Roll-Crusher thyssenkrupp-polysius

Double-Roll-Crushers are used for the crushing or medium-hard rock as well as for sticky and soft materials, i.e. clay, marl, limestone and similar raw materials. Sticky and soft materials are reliably crushed in 2 or 3 stages down to the required product size. Due to the low crushing ration, the thyssenkrupp Double-Roll-Crusher is producing a

Double Roll Crusher Product Information KURIMOTO, LTD.

KURIMOTO, LTD. Product Information, Double Roll Crusher. User-friendly, high-functional Crusher Supports a wide variety of crushed particle sizes. Designed to bite objects between the two rolls and crush the objects using a built-in hybrid mechanism that crushes material by compression action and forcedly discharges the crushed product.

Products

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material. For the industrial beneficiation of raw materials, energy-efficient roll crushers, with high throughput rates, are becoming increasingly important from an economic

Roll Crusher an overview ScienceDirect Topics

Double-roll crushers are able to crush more finely than single-roll crushers, because they are designed with teeth that mesh together rather than rotating past a smooth plate. They can reduce coal to as little as ¼ inch (0.6 cm) topsize, although they are more commonly operated close to 2 inches (5 cm).

Selecting the Right Crushing Equipment Agg-Net

Double-roll crushers offer up to a 3:1 reduction ratio in some applications, depending on the characteristics of the material. Triple-roll crushers offer up to a 6:1 reduction. As a compressive crusher, the roll crusher is well

Double Roll Crusher From American Pulverizer

Available in a range of sizes to meet your exact specifications. Components of the Double Roll Crusher include: Hand pump for safe, easy hydraulic adjustment of crushing rolls; Relief springs on each side that

EXTEC Double Roll Crusher SpecificationsTechnical Data (2004

EXTEC Double Roll Crusher SpecificationsTechnical Data (2004-2008) Rate this machine now! Operating weight: 46t Transport length: 14.0m Transport width: 2.8m Transport height: 3.3m Plant type: RM Drive: D/Hy Technical specs BuyRent PartsComponents EventsNews Transport ContactsHelp Technical specs Double Roll

Double Roll Crusher 911Metallurgist

The double-roll crushers accept feed sizes up to 10 mm, though larger feed can be effectively handled in certain applications. The machine is protected against damage due to unbreakable materials like nut or bolts,

200-450 TPH Rock Double Roller Crusher High Yield

China 200-450 TPH Rock Double Roller Crusher High Yield Environmental Friendly, Find details about China Double Roller Crusher from 200-450 TPH Rock Double Roller Crusher High Yield Environmental Friendly Sichuan BENO Energy Conservation and Environmental Protection Technology Co., Ltd..

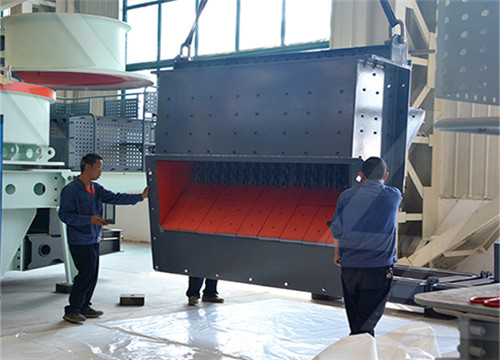

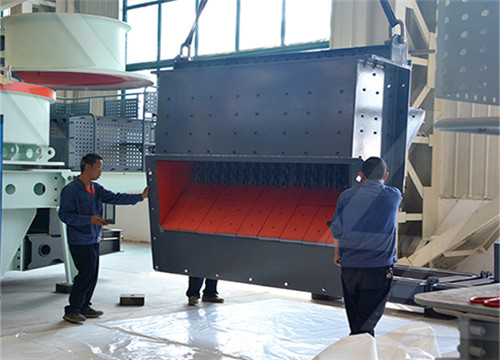

What is a double roll crusher MIXING AND CRUSHING

2022年12月15日The double roll crusher is mainly composed of rollers, roller support bearings, pressing, adjusting devices and driving devices. Install a wedge or shim adjusting device between the two rollers, so install an adjusting bolt in front of the wedge to adjust the fineness of the device material.

Roll crusher working principle Henan Deya Machinery Co., Ltd.

2021年8月20日Double roll crusher is a commonly used roll crusher, whose structure is detailed in Figure 1. Its crushing mechanism is a pair of cylindrical rolls mounted horizontally parallel to each other on the frame. The material is added to the feed box 16 and falls on top of the rotating rolls.

Energy Saving Double Toothed Roll Crusher images Double Roller

Energy Saving Double Toothed Roll Crusher images show details of quality Double Roller Crusher from China Suppliers of . On China.cn; Search; Sign in|Join Free; Sign out Please refer to the specifications. Capacity(t/h): 2-140: Place of Origin: Henan, China: Brand Name: Great Wall: Model Number: PG Series Double Roller Crusher:

Roll Crushers Double Roll Crusher Manufacturer from Howrah

Roller Manganese Casting roller. The rollers are all over marching. Bearing Special double roller bearing 4 nos. Bearing Block C.S casting ,1030 GR-I. Motor Chassis Attached with body. SPECIFICATION Roller Size 20” dia 24” dia 30” dia Roller Face 20” 30” 36” Power Requer 40HP 80HP 100HP No. of Motor 2NOS.20HP 2NOS. 40HP 2NOS.50HP