Fitting Concave To 1000 Cone Crusher

What affects cone crusher performance? — SRP

What affects cone crusher performance? To make sure that your crusher is delivering the desired product, and maximizing its efficiency and productivity, there are a few potential

进一步探索

Crusher Performance FactorsTips to maximize crushing efficiency PitQuarry根据热度为您推荐•反馈

Cone Crusher Liners: How to Select and When to Change

根据热度为您推荐•反馈预计阅读时间:2 分钟

Cone Crusher Explained saVRee

IntroductionCone Crushers HistoryPurpose of CrushersCrusher TypesCone Crusher Components

There are threecommon crushers used at mining and processing plants: 1. Gyratory Crushers 2. Jaw Crushers 3. Cone Crushers Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher. Cone cr...

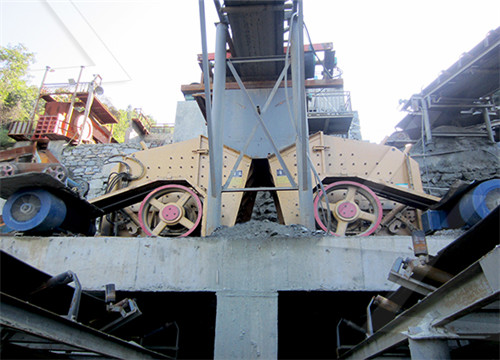

1000 MAXTRAK

The high performance ® 1000 Maxtrak is a small to medium sized cone crusher which has been designed for direct feed applications without pre-screening on

A Detailed Overview of Cone Crushers and What You

2020年6月3日Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and

Cone Crusher Parts Mineral ProcessingMetallurgy

2017年2月19日Cone Crusher MAINSHAFT. The mainshaft is of high grade forged steel, annealed for stress relief. It is tapered to gauge for head center fit. The bottom of the shaft is fitted with a polished bronze step

1000TC Tracked Cone Crusher Tesab Engineering

The Tesab 1000TC Cone Crusher is a Heavy Duty Mobile unit designed to produce High Quality Cubical Aggregates. The superior design consists of thicker manganese for longer life and a specially curved profile allows for

Pegson 1000 Maxtrak Cone Crusher Spare Wear Parts

The Application of 1000 cone crusher parts. Dedicated to 1000 cone crusher, capable of crushing hard and medium hard ore and rock, such as iron ore, limestone,

What affects cone crusher performance? — SRP

To make sure that your crusher is delivering the desired product, and maximizing its efficiency and productivity, there are a few potential issues that you should be alert to. At we have researched the factors that if not properly addressed can cause cone crushers to perform below their optimal level. Crushing chamber selection

Cone Crusher Liners: How to Select and When to

2020年6月23日90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side

MCC Series Cone Crusher Minyu Machinery Corp.

2022年2月24日Minyu Cone Crushers are proven to be one of the most well balanced cone crushers in the world. As a professional cone crusher manufacturer and supplier, we also offer Customized Crushers, Jaw

1000 MAXTRAK

The high performance ® 1000 Maxtrak is a small to medium sized cone crusher which has been designed for direct feed applications without pre-screening on clean rock. At its heart is the Automax® cone crusher which provides excellent reduction and product cubicity for the production of high quality aggregate and sub-base material.

Cone Crusher Explained saVRee

This adjustment varies the size of a cone crusher’s product because the gap between the mantle and concaves is correspondingly increased or decreased. Raising the concaves ( bowl liner) thus increases the

Bowl LinerMantle Wear Resistant Crusher Parts GTEK

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher. 1000 Maxtrak 1000SR 1150 Maxtrak 1300 Maxtrak 1500 Maxtrak: C-1554 C-1550 C-1550P C-1545 C-1545P C-1540 C-1540P C-1540RS: TC1000 TC1150 TC1300

What is the eccentric throw? — SRP

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it doesn’t stay in the center of the

P1000 Mantles and Concaves for Finlay C-1540 Cone Crusher

Our P1000 Mantles and Concaves fit the following models: Finlay C-1540 Cone Crusher. Finlay C–1540 RS Crusher. Samscreen will custom design your replacement cone to your exact specifications. And, our replacement cones are designed with the toughest applications in mind, such as the crushing of mid-hard and above mid-hard rocks and ores.

Cone Crushers mekaglobal

Cone Crushers MCS 900, MCH 900 Technical Specification Cone Crushers are used for crushing especially river gravel basalt and granite. They are also operated to crush hard and abrasive materials in iron, chrome, magnesite and copper mines. Cone crusher has been used as primary, secondary and tertiary crushers for a long time.

Spare parts for Telsmith Cone Crushers

Telsmith cone crusher spare parts and from EXCEL high performance parts have a longer wear life and improved efficiency and throughput. Our cone crusher spare parts are improved over OEM standards, allowing for longer wear life and ease of installation. Abrasion-resistant pipeline fittings Airlift™ vertical conveying Concave ring and

Cone Crushers McLanahan

A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Cone Crusher an overview ScienceDirect Topics

The Gyradisc crushers have head diameters from around 900 to 2100 mm. These crushers are always operated under choke feed conditions. The feed size is less than 50 mm and therefore the product size is usually less than 6–9 mm. View chapter Purchase book Crushers

Fitting Concave To 1000 Cone Crusher suddenlyceliac

Fitting Concave To 1000 Cone Crusher. fitting concave to 1000 cone crusher . La planta de trituracion de arena tph. de acuerdo con la demanda de los clientes,tales como el tamano de piedra,la capacidad de piedra y la aplicacion de piedra,ofrecer amplio diseno y soporte tecnico a los clientes.En situacion normal,la linea de produccion completa se

How Often Should the Crushing Wall and the Concave of the Cone Crusher

2023年2月24日The crushing wall and the concave are important components of the cone crusher. The material is directly rolled and crushed in the crushing chamber composed of the two. Therefore, the wear of the crushing wall and the concave is relatively serious.

1000 MAXTRAK

The high performance ® 1000 Maxtrak is a small to medium sized cone crusher which has been designed for direct feed applications without pre-screening on clean rock. At its heart is the Automax® cone crusher which provides excellent reduction and product cubicity for the production of high quality aggregate and sub-base material.

MCC Series Cone Crusher Minyu Machinery Corp.

2022年2月24日Minyu Cone Crushers are proven to be one of the most well balanced cone crushers in the world. As a professional cone crusher manufacturer and supplier, we also offer Customized Crushers, Jaw

Cone Crusher Liners: How to Select and When to

2020年6月23日90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side

Bowl LinerMantle Wear Resistant Crusher Parts GTEK

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher. 1000 Maxtrak 1000SR 1150 Maxtrak 1300 Maxtrak 1500 Maxtrak: C-1554 C-1550 C-1550P C-1545 C-1545P C-1540 C-1540P C-1540RS: TC1000 TC1150 TC1300

Cone Crusher an overview ScienceDirect Topics

The Gyradisc crushers have head diameters from around 900 to 2100 mm. These crushers are always operated under choke feed conditions. The feed size is less than 50 mm and therefore the product size is usually less than 6–9 mm. View chapter Purchase book Crushers

What is the eccentric throw? — SRP

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it doesn’t stay in the center of the

P1000 Mantles and Concaves for Finlay C-1540 Cone Crusher

The Cones/ Cone Liners / Concaves / Mantles that you order from us will be top-quality and manufactured for the perfect fit in your Cone Crusher, because our engineers have a wealth of experience in the aggregate field. Our P1000 Mantles and Concaves fit the following models: Finlay C-1540 Cone Crusher Finlay C–1540 RS Crusher

How Often Should the Crushing Wall and the Concave of the Cone Crusher

2023年2月24日The crushing wall and the concave are important components of the cone crusher. The material is directly rolled and crushed in the crushing chamber composed of the two. Therefore, the wear of the crushing wall and the concave is relatively serious.

Cone Crushers mekaglobal

Cone Crushers MCS 900, MCH 900 Technical Specification Cone Crushers are used for crushing especially river gravel basalt and granite. They are also operated to crush hard and abrasive materials in iron, chrome, magnesite and copper mines. Cone crusher has been used as primary, secondary and tertiary crushers for a long time.

Spare parts for Telsmith Cone Crushers

Telsmith cone crusher spare parts and from EXCEL high performance parts have a longer wear life and improved efficiency and throughput. Our cone crusher spare parts are improved over OEM standards, allowing for longer wear life and ease of installation. Abrasion-resistant pipeline fittings Airlift™ vertical conveying Concave ring and

CS430 Cone Crusher For Secondary Crushing Applications

This crusher is suitable for a high-capacity secondary crushing application. CS430 cone crusher is characterized by the large intake capability and the high capacity in relation to size, proving to be a versatile and efficient option for many applications. The Automatic Setting Regulation control system (ASRi™) enables real-time

Fitting Concave To 1000 Cone Crusher suddenlyceliac

Fitting Concave To 1000 Cone Crusher. fitting concave to 1000 cone crusher . La planta de trituracion de arena tph. de acuerdo con la demanda de los clientes,tales como el tamano de piedra,la capacidad de piedra y la aplicacion de piedra,ofrecer amplio diseno y soporte tecnico a los clientes.En situacion normal,la linea de produccion completa se

Cone Crushers CMB International Limited

Cone Crushers. The CMB Rockstar 150, 185 and 225 Cone Crushers are modern cast steel, all roller bearing and feature hydraulic adjustment which enables the operator to rapidly change the discharge setting, if required during the crushing operation. These machines feature hydraulics which also incorporate a tramp metal release, automatic

fitting concave to 1000 cone crusher 123chauffage.fr

H4800 Cone Crusher Fitting HP 300 500 your source for CH440 Cone Crushers Search 1000 s of listings Cone Crusher parts Cone Concave Cone Crusher Parts at Best Price in India IndiaMART