Vertical Raw Mill Manual

Bridgeport Vertical Mill Manual UC Berkeley Mechanical

Bridgeport Vertical Mill Manual UC Berkeley Mechanical Engineering

进一步探索

Bridgeport Manuals User Guides CNC ManualBRIDGEPORT MANUAL MILL SPARE PARTSBridgeport Mill Series 1 J Head RepairService Manual InBridgeport Service Manuals Industrial ControlAutomationBridgeport Series 2 ManualsUser Guides根据热度为您推荐•反馈

Bridgeport Vertical Mill (Manual) UC Berkeley

根据热度为您推荐•反馈

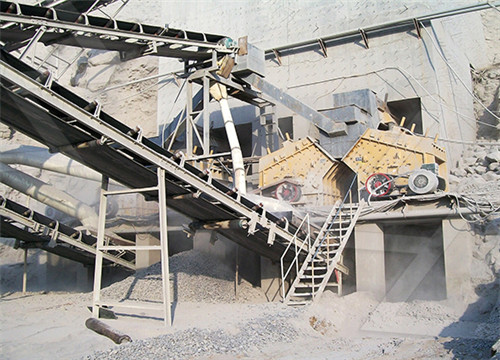

Vertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

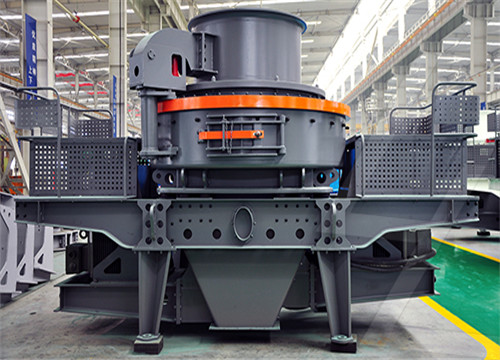

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant. Vertical

进一步探索

Process flow diagram for the cement manufacturing procTypical cement manufacturing process flow diagram [4]. 根据热度为您推荐•反馈

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

Vertica raw mill, also known as vertical roller mill, in the 1920s, the first vertical raw mill in cement plant is designed in German. It is widely used in cement, electric power,

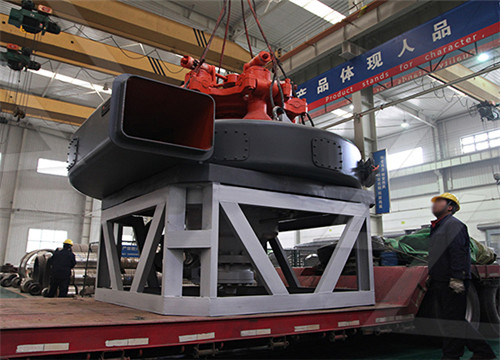

Vertical Raw Mill CHAENG

Vertical raw material mill is an important equipment widely used in the grinding section of cement raw meal (cement raw material) in the cement production process in cement

Vertical raw mill pradeep kumar SlideShare

2013年5月15日1. Vertical raw mill K.P.PRADEEP KUMAR Sr G M Operation Karikkali Works Chettinad Cements Ltd. 2. The principle of vertical mill resembles like ammi kallu, attaankallu, Or ennai chekku

Raw Mill Loesche

Raw Mill. A sustainable step into a successful future: LOESCHE delivers a By admin. on Feb 10th, 2021 . Cement. Sohag LOESCHE is involved in the new construction of a large cement plant in Egypt with

Vertical Raw Mill ball mills supplier

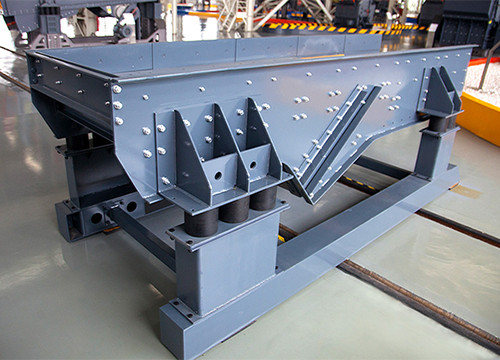

Vertical Raw Mill Feeding size: 35-110mm Capacity: 12-350t/h Motor power: 255-3600kW Applications: It can be used for grinding limestone, gypsum, siliceous, coal and other materials. It is mainly used in cement

Vertical Raw Mill Manual Crusher Mills, Cone Crusher, Jaw Crushers

pdf vertical grinding mill for cement free manual This page is provide professional pdf vertical grinding mill for cement free manual information for you,

Manual Mills Sharp Industries Inc.

View Horizontal Knee Mill Models Vertical / Horizontal Knee Mills With 2 spindles on the same machine, vertical and horizontal operations can be performed in one set up. This increase productivity and accuracy. It can

Bridgeport Vertical Mill Manual UC Berkeley Mechanical

Bridgeport Vertical Mill Manual UC Berkeley Mechanical Engineering

Our modern vertical roller mill takes you further

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts

OK™ raw mill Reliable and efficient raw material grinding

Vertical Roller Mills (VRMs) have been the standard option for raw materials grinding in the cement industry for several decades. has supplied the global cement industry with leading VRM designs for all applications since they were first brought to market. The OK™ mill has been ’s standard cement VRM since 1993.

Vertical Raw Mill Great Wall

Introduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles.Vertical roller mills are widely used in the concrete and mining fields, and are also used to process

Vertical Raw Mill ball mills supplier

Vertical Raw Mill Feeding size: 35-110mm Capacity: 12-350t/h Motor power: 255-3600kW Applications: It can be used for grinding limestone, gypsum, siliceous, coal and other materials. It is mainly used in cement

How Vertical Grinding Mills Work (Coal Pulverizer Example)

2019年6月14日How Vertical Grinding Mills Work (Coal Pulverizer Example) saVRee 192K subscribers Join Subscribe 1K Share 58K views 3 years ago Industrial Engineering Want to continue learning

Cincinnati Milling Machine Co. (Milacron) Publication Reprints

Cincinnati Milling Machine Cutter Grinder Catalog. 106. Black, Dennis. 01/09/2021. 1983 Jun (reprint of 1963 original) Service Manuals. Parts and Service Manual for Cincinnati Milacron Toolmaster Milling Machine. 120.

INVT GD5000 MV Drive for Cement Raw Mill 11KV 4MW Motor

2020年4月4日For vertical raw mill application, the main purpose to use inverter is soft-starting the motor and adjusting the speed, and it will also save energy. Considering high environment temperature, the MVD need to be de-rated, so the selection is as follows: GD5000 Series High Voltage Inverter Instruction Manual,Shenzhen Invt Electric Co.,

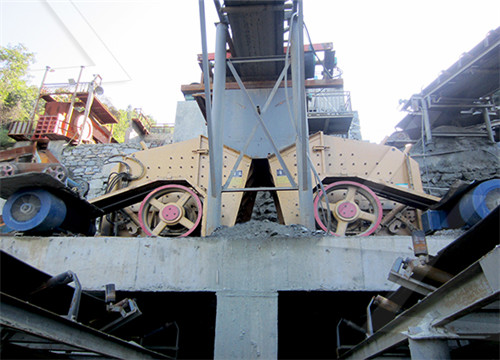

Vertical Raw Mill Manual Crusher Mills, Cone Crusher, Jaw

Antigua and Barbuda Raw mill equipped with High efficiency . More than 80% of the new installations for raw mills are vertical 50-600tph crusher cone 2 manual in Egypt; LS vertical crusher cost; rock crusher for sale Albania;

important operation tips for cement vertical mill

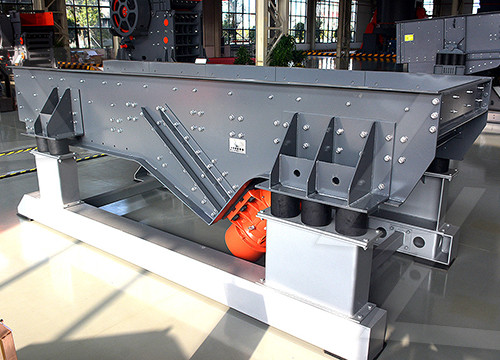

Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc. There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The

INVT GD5000 MV Drive for Cement Vertical Raw Mill 6.3KV

2020年4月4日Manual Bypass Cabinet: 3. System Configuration. 3.1 VFD system instruction. According to the demand on site, Increase raw milling production. The vertical mill motor running at 60Hz, which is faster than before, so it can increase raw milling production. 3. Very low torque pulse without causing the resonance between the

Plant engineering solutions for any mission Loesche

Plant engineering solutions for any mission Loesche

Grinding technology and mill operations

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding.

Bridgeport Vertical Mill Manual UC Berkeley Mechanical

Bridgeport Vertical Mill Manual UC Berkeley Mechanical Engineering

Our modern vertical roller mill takes you further

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts

Vertical Raw Mill Great Wall

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum.

Cement Raw Mill in Cement Plant for Cement Raw

Raw Mill Feeding size: ≤30mm Capacity: 21-210t/h Functional advantages: Wet and dry operation, fully-functional Applications: It widely used in cement production, silicate products, new building materials, ferrous and

Vertical Raw Mill Manual Crusher Mills, Cone Crusher, Jaw

Antigua and Barbuda Raw mill equipped with High efficiency . More than 80% of the new installations for raw mills are vertical 50-600tph crusher cone 2 manual in Egypt; LS vertical crusher cost; rock crusher for sale Albania;

INVT GD5000 MV Drive for Cement Raw Mill 11KV 4MW Motor

2020年4月4日For vertical raw mill application, the main purpose to use inverter is soft-starting the motor and adjusting the speed, and it will also save energy. Considering high environment temperature, the MVD need to be de-rated, so the selection is as follows: GD5000 Series High Voltage Inverter Instruction Manual,Shenzhen Invt Electric Co.,

Bridgeport Manuals User Guides CNC Manual

We have 20 Bridgeport manuals for free PDF download. Bridgeport Manuals CNC Programming, OperatingMaintenance Manuals. Bridgeport Boss 4 Manual; Bridgeport Boss 5 Manual; Bridgeport M-156 Student Manual Milling Drilling Machines. Bridgeport R2E3 Series I CNC Operating Manual.

Cincinnati Milling Machine Co. (Milacron) Publication Reprints

Cincinnati Milling Machine Cutter Grinder Catalog. 106. Black, Dennis. 01/09/2021. 1983 Jun (reprint of 1963 original) Service Manuals. Parts and Service Manual for Cincinnati Milacron Toolmaster Milling Machine. 120.

vertical raw mill manual Imgur

Find, rate and share the best memes and images. Discover the magic of the Internet at Imgur.

important operation tips for cement vertical mill

Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc. There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The

INVT GD5000 MV Drive for Cement Vertical Raw Mill 6.3KV

2020年4月4日The vertical mill motor running at 60Hz, which is faster than before, so it can increase raw milling production. 3. Very low torque pulse without causing the resonance between the motor and other mechanical devices, and reducing the transmission mechanism wearing. 4. Perfect output waveform, less than 4% of distortion. 5.

Horizontal vs. Vertical Mills: 10 Key Differences

2023年1月11日Whether using a manual or CNC mill, machine shops choose from two basic types of milling machines: the vertical and the horizontal. In this guide, we will compare the horizontal and vertical

Grinding technology and mill operations

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding.