Minimizing Mining Gold Mining Machine Machine Maintenance

A guide to predictive maintenance for the smart mine

2020年4月16日Barrick Gold saved $500,000 due to their newfound ability to detect and address failures as well as reduced the total number of

Optimizing OperationsMinimizing Impact Cat

2022年9月21日When explaining the wide variety of offerings Caterpillar provides to help customers in the areas of sustainable mining, the company boils the solutions down to

Investigation of Causes of Mining Machines Maintenance

2015年12月15日The task of this qualitative analysis is to undertake corrective or preventive measures to eliminate the problems of mining machines maintenance, after

(PDF) Predictive Maintenance of Mining Machines Using

2019年1月1日PDF On Jan 1, 2019, P. Kruczek and others published Predictive Maintenance of Mining Machines Using Advanced Data

Mining equipment reliability and maintenance MRO

2018年5月7日An additional reliability improvement strategy that should be considered for improving plant equipment in the mining industry is the application of total productive maintenance (TPM) that minimizes the six

Safety Analysis of Mining Machines Specific Maintenance

2015年12月15日From the standpoint of the mining machines safety, it should be stressed that in some researches, the expression “specific” is used for the critical

Maintenance indicators for underground mining equipment : a

@inproceedings{Gustafson2011MaintenanceIF, title={Maintenance indicators for underground mining equipment : a case study of automatically versus manually

Strategies to minimize mining operating costs The Mine

Use enhanced sequencing to optimize mine sites. Increase cut-off grades to raise the bar on quality. Increase the production from mines where the cost is low and prioritize them. Curb capital expenditures on mines that have

Repair Options for Mining Equipment Cat Caterpillar

Repair-before-failure maintenance ensures the lowest cost of repair. It also gets you the best turnaround time for an end-of-life component or machine rebuild. Your Cat ® dealer

Mining Machines and Earth-Moving Equipment SpringerLink

This book presents central problems in the design, research and maintenance of large-size mining machines for open pits, mobile earth-moving machinery, hydraulic hammers for mining and civil engineering, and screening processes for bulk materials. It brings together the insights of numerous respected academics to offer a thorough and

Investigation of Causes of Mining Machines Maintenance Problems

2015年12月15日The method of cause-effect diagram will be used in the subject investigation to detect and systematize factors (causes) that affect the results performing for the mining machines maintenance operation, i.e. sources that cause a maintenance problem [].The task of this qualitative analysis is to undertake corrective or preventive

Mining equipment reliability and maintenance

2018年5月7日An additional reliability improvement strategy that should be considered for improving plant equipment in the mining industry is the application of total productive maintenance (TPM) that minimizes the six

Filter cleaning machine could dust thousands off maintenance bill

2011年5月18日At $20,000 per machine, Diversi-Tech claims it can save mining companies thousands in maintenance costs. According to the company’s brochure, a surface mine with 50 dozers and haulers would pay

Improving Mining Equipment Maintenance and Safety

2022年11月14日Like other equipment, mining equipment maintenance is also essential. Maintenance is the only way to improve the performance of special equipment. Moreover, if the equipment is not maintained at the right time, it may turn into the faulty one. It also impacts the workers’ safety and even the business’s reputation.

Strategies to minimize mining operating costs The

An iron ore mine that experienced ‘boom-time’ growth in the mid to late 2000s needed to improve productivity, thereby reducing the costs. It was suffering the effects of inefficient mine management and poor workforce

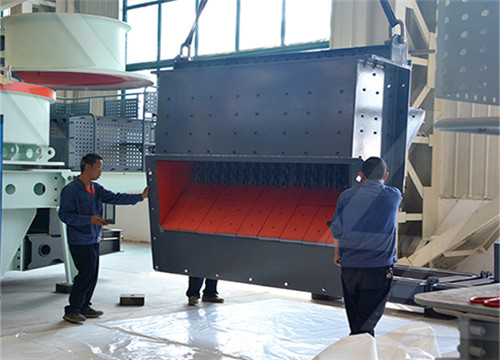

Minimizing Crusher Production Losses During Maintenance

2000年4月1日Canadian Mining Journal Staff April 1, 2000 12:00 am. One of the world’s major crusher manufacturers, Svedala Industri AB, is introducing a ‘cassette’ system for carrying out crusher maintenance. The unit to be worked on is simply lifted out and replaced by an identical crusher until the original unit is ready to go back into production.

8 Pieces of Gold Mining Equipment That Help You Recover More Gold

2023年2月15日FTM company is committed to providing gold miners with efficient and robust gold mining equipment starting from crushing, grinding, gravity separation, flotation, helping them get a high gold recovery rate. Whether processing placer gold or gold-containing quartz stone powder, you must use beneficiation equipment to separate gold

Underground Mining Equipment For Gold Mine Fucheng LHD

Underground mining is very important for gold mining, especially non-ferrous metals and gold mining. About 90% of mines use underground mining. Therefore, underground mining equipment for gold mine also has a certain demand. Underground Jumbo Drill. Underground Scaling Jumbo. Underground Mining Scooptram. Underground Mining

Predictive Maintenance Using Machine Learning and Data Mining

2020年11月30日In every business, the production of knowledge, coming from the process of effective information, is recognized as a strategic asset and source of competitive advantage. In the field of railways, a vast amount of data are produced, which is necessary to be assessed, deployed in an optimum way, and used as a mechanism, which will lead

Command Cat Caterpillar

Mining Surface Mining Surface Mining Technology Command THE RIGHT LEVEL OF AUTOMATION CAT® MINESTAR™ COMMAND The biggest development in technology over the last decade has been in machine

5 Strategies To Minimize Mining Operating Costs

Use enhanced sequencing to optimise mine sites. Increase cut-off grades to raise the bar on quality. Increase the production from mines where the cost is low and prioritize them. Curb capital expenditures on mines which have a lower potential for production and won’t be around for long.

8 strategies for reclaiming efficiency and lowering costs in mining

2015年2月5日Here are some strategies to consider, from Deloitte’s “Mining spotlight on sliding productivity and spiraling costs.”. 1. Strengthen mine planning. Refocus on high quality production by increasing cut off grades. Reduce capital expenditures in properties with lower production potential and shorter mine lives.

Repair Options for Mining Equipment Cat Caterpillar

Maintenance Repair Options Mining Equipment Repair Options for Mining Equipment To get the best value from your mining equipment — and keep it performing at its best, shift after shift, year after year — it’s critical that you perform component repairs on

Investigation of Causes of Mining Machines Maintenance Problems

2015年12月15日The method of cause-effect diagram will be used in the subject investigation to detect and systematize factors (causes) that affect the results performing for the mining machines maintenance operation, i.e. sources that cause a maintenance problem [].The task of this qualitative analysis is to undertake corrective or preventive

(PDF) Predictive Maintenance of Mining Machines

2019年1月1日PDF On Jan 1, 2019, P. Kruczek and others published Predictive Maintenance of Mining Machines Using Advanced Data Analysis System Based on the Cloud Technology Find, read and cite

(PDF) Mobile lubrication and filling units to reduce mining machines

2019年7月10日When carrying out technical maintenance (MOT), including lubrication and filling works, at the site of operation of mining machines due to the remoteness from repair shops and warehouses of fuels

The mine-to-market value chain: A hidden gem McKinsey

To date, the mine-to-market value chain has often been handled within organizational silos, which have limited coordination and real-time data exchange. Understanding the mining value chain as a single integrated process, however, can allow companies to take a truly comprehensive view of performance. Mine-to-market performance enhancements

Maintenance ManagementEquipment International Mining

2012年11月1日This greatly assists and improves boom, stick and bucket cylinder maintenance on large shovels, for example. With up to a 10 t capacity, it can handle 85 to 630 mm cylinder diameters. The CH 10 offers smooth and accurate workflow, safety, faster operation, is easy to use and saves downtime, according to Manitou.

Improving Mining Equipment Maintenance and Safety

2022年11月14日Like other equipment, mining equipment maintenance is also essential. Maintenance is the only way to improve the performance of special equipment. Moreover, if the equipment is not maintained at the right time, it may turn into the faulty one. It also impacts the workers’ safety and even the business’s reputation.

Filter cleaning machine could dust thousands off maintenance bill

2011年5月18日At $20,000 per machine, Diversi-Tech claims it can save mining companies thousands in maintenance costs. According to the company’s brochure, a surface mine with 50 dozers and haulers would...

Strategies to minimize mining operating costs The

An iron ore mine that experienced ‘boom-time’ growth in the mid to late 2000s needed to improve productivity, thereby reducing the costs. It was suffering the effects of inefficient mine management and poor workforce

Minimizing Crusher Production Losses During Maintenance

2000年4月1日Canadian Mining Journal Staff April 1, 2000 12:00 am. One of the world’s major crusher manufacturers, Svedala Industri AB, is introducing a ‘cassette’ system for carrying out crusher maintenance. The unit to be worked on is simply lifted out and replaced by an identical crusher until the original unit is ready to go back into production.

Predictive Maintenance Using Machine Learning and Data Mining

2020年11月30日The adoption of the extensive data and using machine learning-data mining with decision trees to the maintenance and the function of the equipment can increase productivity and decrease the cost of maintenance [ 1 ].

Mining Machines and Earth-Moving Equipment SpringerLink

This book presents central problems in the design, research and maintenance of large-size mining machines for open pits, mobile earth-moving machinery, hydraulic hammers for mining and civil engineering, and screening processes for bulk materials. It brings together the insights of numerous respected academics to offer a thorough and

Underground Mining Equipment For Gold Mine Fucheng LHD

We can provide you with the gold mining equipment or gold miners equipment you need. With the continuous improvement of the level of science and technology, the rapid development of underground gold mining technology and underground mining equipment has been promoted. This also provides sufficient conditions for gold mining.

5 Strategies To Minimize Mining Operating Costs

Use enhanced sequencing to optimise mine sites. Increase cut-off grades to raise the bar on quality. Increase the production from mines where the cost is low and prioritize them. Curb capital expenditures on mines which have a lower potential for production and won’t be around for long.

Repair Options for Mining Equipment Cat Caterpillar

Maintenance Repair Options Mining Equipment Repair Options for Mining Equipment To get the best value from your mining equipment — and keep it performing at its best, shift after shift, year after year — it’s critical that you perform component repairs on

- 岩盐生产利用

- 石料破碎机郑州通江机械

- Quarry

- 300 Tonnes Per Hour Stone Crusher

- 石膏遇热分解体现了什么性能

- 云南铁虎牌厂家电话

- 供应高速公路铁路专用石料生

- Flowchart Of Coal Processing Plant

- China Product Crushing Jaw Crusher Cost Of Mining Milling Machine In Uganda

- 20 200 Th Arena Chancadora De La Planta

- 石头破碎机石子

- 选矿自动化、信息化

- vs系列新型制沙机

- Bokoni Platinum Mine Bursary Scheme

- 陕西合阳县宋建斌