Flowchart Of Coal Processing Plant

11.10 Coal Cleaning US EPA

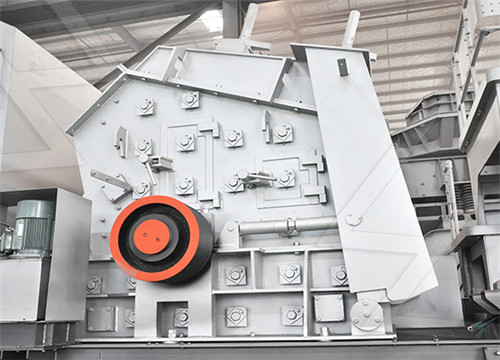

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal

Coal Processing Multotec

根据热度为您推荐•反馈

Simplified process flow diagram of the coal-fired power

In this , the performance of a coal-fired plant is assessed using exergy analysis. The plant components were analysed, the exergy destruction of each component was calculated, and the...

Coal Processing Plant 3D Visualization YouTube

2011年5月25日433 subscribers Pixel Studios created a comprehensive 3D Visualization (visual walkthrough) which features every step involved in procuring coal, stage by stage. The three

Flow Chart Of Coal Processing Plant GitHub Pages

Coal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine

Coal Mining Processing Equipment Flow Chart Cases JXSC

After removing the coal from the ground, the miners may send it to a preparation plant near the mining site. The plant cleans and processes coal to remove rocks, dirt, ash, sulfur,

PROCESS FLOW CHARTS AND PLANT LAYOUT FLOW

the flow chart may look somewhat like as in Fig. 3.1. Fig. 3.1 Flow chart for vegetable dehydration For preparation of a flow chart, first of all we have to know the sequence of

COAL HANDLING PLANT / Working ProcessFlow

2021年9月5日COAL HANDLING PLANT / Working ProcessFlow Diagram of Coal handling System in Thermal Power PlantThermal Power plantAbout VideoThis video is

Coal Mining Process Flow Chart Diagram ione

2020年4月22日Coal Mining Process Flow Chart Diagram. The key role played by our coal reserves in the economy is illustrated by the fact that eskom is the 7th largest

How a Coal Plant Works TVA

Coal-fired plants produce electricity by burning coal in a boiler to produce steam. The steam produced, under tremendous pressure, flows into a turbine, which spins a generator to create electricity. The steam is then cooled, condensed back into water and returned to the boiler to start the process over.

Flowsheet of a modern coal preparation plant

A coal preparation plant typically has multiple cleaning circuits based on size of coal particles. The traditional way of optimizing the plant output and meeting the product constraints...

11.10 Coal Cleaning US EPA

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation. A process flow diagram for a typical coal cleaning plant is presented in Figure 11.10-1.

7.5. SNG from Coal: ProcessCommercialization

Costs of producing SNG via gasifying coal were estimated by the 2007 interdisciplinary MIT study to be from 6.7 to 7.5 dollars per million Btus. 1. Process Efficiency. Table 1 lists some of the published plant

Flow Chart Of Coal Processing Plant GitHub Pages

The people with the industry machining process and industrial coal by principle of coal basically is the same, the difference is the raw coal after crusher, need of raw coal and loess a uniform mixing, stirring after can

Coal Production Cost, Plant Cost Analysis 2022-2027

2023年3月7日Manufacturing Process: Process Flow, Material Flow, Material Balance Raw Material and Product/s Specifications: Coal is made from the remains of the plant that have condensed, solidified, chemically modified, and metamorphosed by heat and pressure over time. It dominantly constitutes carbon and hydrocarbons containing energy

Electrical capacitance tomography-based estimation of slug flow

2023年3月7日Fig. 3 depicts the ECT system installed within an industrial process plant. The pneumatic conveyor is part of a pulverized coal injection (PCI) system within a steel plant. The transported bulk material is coal powder with an average particle size of approximately d 50 ≈ 30 µm, the material belongs to Geldart

Coal-oxygen process provides CO/sub 2/ for enhanced recovery

A description is given of a process which is based on the production of CO/sub 2/ in electric power plants that burn coal in an O/sub 2/-CO/sub 2/ mixture (not air). The process eliminates the need for flue gas desulfurization and carbon dioxide purification required in more conventional approaches to recovery from flue gases. It is environmentally

Plant Maintenance Process Flow Chart lia.erc.gov.ph

Process boundaries eFFICIeNCY oUTLooK For Power GeNerATIoN FroM CoAL 6 tips for fixing your kitting process Plant Services April 28th, 2018 These experienced workers have been doing predictive maintenance on plant plant,process,maintenance,flow,chart Created Date: 3/8/2023 1:03:24 PM

Coal Processing an overview ScienceDirect Topics

1982年8月9日The structure of coal was described in Chapter 6 and is thought to be a highly linked amorphous polymer consisting of aggregates connected by relatively weak cross-links. If the cross-links are broken by pyrolysis, the resulting fragments are closely related to, if not the same as, coal liquids.

Teori Dasar Coal Processing Plant (CPP) PDF

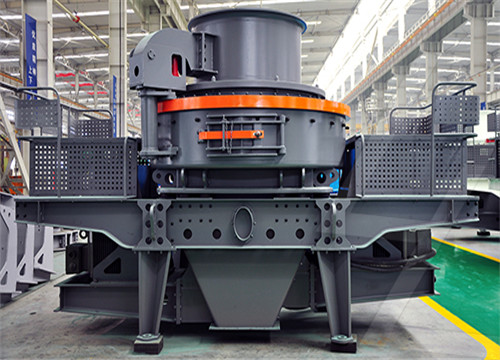

of 23. BAB III TEORI DASAR Operasi crushing system yang dilakukan di Coal Processing Plant 3 (CPP3) merupakan proses pengecilan ukuran batubara hasil penambangan sehingga akan diperoleh ukuran batubara sesuai permintaan Konsumen yaita SO mm yang mana dalam proses ini terjadi pula proses peneampuran batubara ( coal blending ). 3.1

12.2 Coke Production US EPA

The blended coal mass is heated for 12 to 20 hours for metallurgical coke. Thermal energy from the walls of the coke chamber heats the coal mass by conduction from the sides to the middle of the coke chamber. During the coking process, the charge is in direct contact with the heated wall surfaces and develops into an aggregate "plastic zone".

Coal preparation plant Wikipedia

The coal delivered from the mine that reports to the coal preparation plant is called run-of-mine, or ROM, coal. This is the raw material for the CPP, and consists of coal, rocks, middlings, minerals and contamination. Contamination is usually introduced by the mining process and may include machine parts, used consumables and parts of ground

Flow Diagram of a Steam Thermal Power Plant Electrical4U

2012年2月24日Flow Diagram of a Steam Thermal Power Plant. A thermal power generating plant works based on the Rankine Cycle. There are mainly three primary inputs given to thermal power generating plants for producing electricity. These three most essential elements are coal, air, and water. Coal is used as fuel here because we are

How a Coal Plant Works TVA

Coal-fired plants produce electricity by burning coal in a boiler to produce steam. The steam produced, under tremendous pressure, flows into a turbine, which spins a generator to create electricity. The steam is then cooled, condensed back into water and returned to the boiler to start the process over.

11.10 Coal Cleaning US EPA

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation. A process flow diagram for a typical coal cleaning plant is presented in Figure 11.10-1.

7.5. SNG from Coal: ProcessCommercialization

Costs of producing SNG via gasifying coal were estimated by the 2007 interdisciplinary MIT study to be from 6.7 to 7.5 dollars per million Btus. 1. Process Efficiency. Table 1 lists some of the published plant

Coal Extraction and Processing Description WordPress

Coal Extraction and Processing Description WordPress

Electrical capacitance tomography-based estimation of slug flow

2023年3月7日Fig. 3 depicts the ECT system installed within an industrial process plant. The pneumatic conveyor is part of a pulverized coal injection (PCI) system within a steel plant. The transported bulk material is coal powder with an average particle size of approximately d 50 ≈ 30 µm, the material belongs to Geldart

What Is Coal Power Plant and How Does it Work?

Coal-fired plants produce electricity by burning coal in a boiler to produce steam. The steam produced, under tremendous pressure, flows into a turbine, which spins a generator to create electricity. The steam is then

Coal Production Cost, Plant Cost Analysis 2022-2027

2023年3月7日Manufacturing Process: Process Flow, Material Flow, Material Balance Raw Material and Product/s Specifications: Coal is made from the remains of the plant that have condensed, solidified, chemically modified, and metamorphosed by heat and pressure over time. It dominantly constitutes carbon and hydrocarbons containing energy

Plant Maintenance Process Flow Chart lia.erc.gov.ph

Process boundaries eFFICIeNCY oUTLooK For Power GeNerATIoN FroM CoAL 6 tips for fixing your kitting process Plant Services April 28th, 2018 These experienced workers have been doing predictive maintenance on plant plant,process,maintenance,flow,chart Created Date: 3/8/2023 1:03:24 PM

Coal-oxygen process provides CO/sub 2/ for enhanced recovery

A description is given of a process which is based on the production of CO/sub 2/ in electric power plants that burn coal in an O/sub 2/-CO/sub 2/ mixture (not air). The process eliminates the need for flue gas desulfurization and carbon dioxide purification required in more conventional approaches to recovery from flue gases. It is environmentally

Teori Dasar Coal Processing Plant (CPP) PDF

of 23. BAB III TEORI DASAR Operasi crushing system yang dilakukan di Coal Processing Plant 3 (CPP3) merupakan proses pengecilan ukuran batubara hasil penambangan sehingga akan diperoleh ukuran batubara sesuai permintaan Konsumen yaita SO mm yang mana dalam proses ini terjadi pula proses peneampuran batubara ( coal blending ). 3.1

12.2 Coke Production US EPA

The blended coal mass is heated for 12 to 20 hours for metallurgical coke. Thermal energy from the walls of the coke chamber heats the coal mass by conduction from the sides to the middle of the coke chamber. During the coking process, the charge is in direct contact with the heated wall surfaces and develops into an aggregate "plastic zone".

An Improved Flexible Solar Thermal Energy Integration Process for

2017年9月25日An improved flexible solar-aided power generation system (SAPG) for enhancing both selective catalytic reduction (SCR) de-NOx efficiency and coal-based energy efficiency of coal-fired power plants is proposed. In the proposed concept, the solar energy injection point is changed for different power plant loads, bringing about different

Coal Fired Thermal Power Station Explained saVRee

Coal is delivered to the plant via road, rail or ship, and deposited in a coal yard.Stacker reclaimers are used to gather coal and deposit it into hoppers, the hoppers then feed flatbed conveyors.Conveyors transport the coal from the coal yard to day silos within the main power station building. Each day silo contains enough coal for a set period of time when

Environmental, Health and Safety Guidelines for Coal

COAL PROCESSING APRIL 30, 2007 4 WORLD BANK GROUP particulate emissions. Heavy metals present in coal may be released as air emissions from the coal gas ification process. Most heavy metals can be removed through a wet scru bber. Absorption technology may be required to remove mercury in coal with higher mercury content.