Dry Crusher Materrial In A Ball Mills

How it Works: Crushers, Grinding Mills and Pulverizers

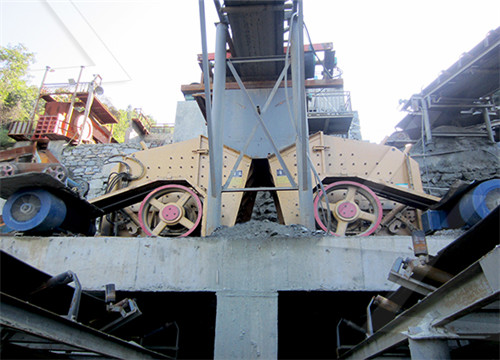

2017年6月2日Rock crusher. Material is reduced by crushers and grinders by fracturing, which takes place when the material is put under

What is a dry ball mill? linkedin

2023年3月7日Published Mar 7, 2023. + Follow. A dry ball mill is a grinding machine that uses a dry powder to grind materials, such as ceramics, minerals, and chemicals. The

Dry Grinding and Wet Grinding of Ball Mill China Crusher Mesto

2021年11月29日The material and the grinding medium are mixed together and collide with each other and squeeze. If it is dry grinding, because there is no material blocking

Ball Mills Industry Grinder for Mineral Processing JXSC

2018年1月30日The ball miller machine is a tumbling mill that uses steel milling balls as the grinding media, applied in either primary grinding or secondary grinding applications. The feed can be dry or wet, as, for the

Dry ball mill,ball mill machine, ball mill crusher, ball mill

Product introduction:The dry ball mill is a cylindrical tube mill, adopting multiple-cabin, characterized by high grinding efficiency, large capacity of a single machine, low power consumption, and low dust pollution.It is

Ball mill, Grinding machine, Wet ball mill, Dry ball mill,

2014年5月22日Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products. New 2.9K views 1 year ago

Dry Continuous Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Shanghai liming Wet Ball Mill is suitable for both dry and wet grinding of various kinds of materials. Easy installation, long-time continuous operation 3. Crusher Machine ?

Planetary Ball Mill JXSC Machine

Planetary ball mill is mainly used in fine grinding operations such as soil, geology, environmental protection, third-party testing, agriculture and animal husbandry,

Dry Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Ball Mill is crucial equipment for Grinding after materials are crushed. materials, fertilizer, porcelain and glass industry etc. Ball Mill has two ways of Grinding: dry

Ball Mill cm-crusher

The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non

Top 5 product-specific milling technologies used in

2017年7月7日Impact and attrition size-reduction methods include air classifying mills, pin mills, hammer mills and jet mills. Shear, impact and compression methods are used in media or ball mills. The five types of

Autogenous GrindingSemi Autogenous Grinding

2017年7月20日Where in conventional rod and ball mill plants there are usually 3 to 4 stages of crushing followed by 1 to 3 stages of grinding, depending on ore fineness and hardness, primary autogenous plants

Dry Grinding and Wet Grinding of Ball Mill China Crusher

2021年11月29日The material and the grinding medium are mixed together and collide with each other and squeeze. If it is dry grinding, because there is no material blocking in the cracks, it is very likely that the cracks will be squeezed smaller and smaller during the extrusion process, which will cause grinding.

Ball Mill Eastman Rock Crusher

Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit. The feed materials can be dry or wet, they are

HPGR High Pressure Grinding Rolls Mineral

2016年7月13日The expansion circuit includes eight MP1250 cone crushers, eight HPGRs (also 2.4 x 1.7-m units, with 5 MW each), and six ball mills (22 MW each), for installed comminution power of 180 MW.

Planetary Ball Mill JXSC Machine

Planetary ball mill is mainly used in fine grinding operations such as soil, geology, environmental protection, third-party testing, agriculture and animal husbandry, agricultural product quality, resources and environment, heavy metal analysis, or laboratory dry and wet research materials.

Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling

2014年5月22日Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

Ball Mill cm-crusher

The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

Dry Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Ball Mills, cement mill, slag mill, tube mill. RSG Inc supplies dry ball milling systems in the range of 125 HP (100 Kw) to 5500 HP (4200 Kw). Dry ball mills are effective grinding systems in the general range of .

(PDF) Comminution in mineral processing

2018年11月19日6.3 Grinding by dry grinder Hammer mill and ball mill use . suspended and further crushes the rock into fine gravel size material. Crusher head design provides .

ball mill manufacturer in egypt

2023年3月10日Whether you need a small laboratory ball mill or a large industrial-scale machine, we have the expertise to deliver the right equipment for your needs. We take pride in our ability to provide high

CERAMIC MATERIALS I Mu

Ball mills are the most commonly used piece of equipment for milling. However, vibratory mills, attrition mills, and fluid energy mills also are used. Crushing and grinding typically are dry processes; milling may be a wet or dry process. In wet milling, water or alcohol commonly is used as the milling liquid. Asst. Prof. Dr.

Ball mill Sandrock Mining

A ball mill can divide into 2 types, wet ball mill, and dry ball mill. Ball mill is a mineral processing machine for milling the materials into powders after they are crushed. It is widely applied to the production of cement, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and

ball mill, ball grinding mill, ball mill machine Desen Machinery

Materials out of crusher need to go into Ball Mill for further grinding. It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry. The ore grinding methods

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日Steel-Head Ball-Rod Mills are available in any one of five different types of discharge: Overflow, perforated overflow, return spiral, grate, and peripheral. To best serve your needs, the Trunnion can be

Top 5 product-specific milling technologies used in

2017年7月7日A ball mill grinds material by rotating a cylinder filled with media (typically metallic or ceramic balls) mixed with a continuous flow of feed and recycled material. At slower rotational speeds, the grinding

What is a dry ball mill? linkedin

2023年3月7日Published Mar 7, 2023. + Follow. A dry ball mill is a grinding machine that uses a dry powder to grind materials, such as ceramics, minerals, and chemicals. The dry ball mill is made up of a

(PDF) Comminution in mineral processing

2018年11月19日6.3 Grinding by dry grinder Hammer mill and ball mill use . suspended and further crushes the rock into fine gravel size material. Crusher head design provides .

Ball Mill Eastman Rock Crusher

Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit. The feed materials can be dry or wet, they are

Planetary Ball Mill JXSC Machine

Planetary ball mill is mainly used in fine grinding operations such as soil, geology, environmental protection, third-party testing, agriculture and animal husbandry, agricultural product quality, resources and environment, heavy metal analysis, or laboratory dry and wet research materials.

Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling

2014年5月22日Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

Ball Mill cm-crusher

The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

Dry Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Ball Mills, cement mill, slag mill, tube mill. RSG Inc supplies dry ball milling systems in the range of 125 HP (100 Kw) to 5500 HP (4200 Kw). Dry ball mills are effective grinding systems in the general range of .

Hammer Mill Operating Principle Mineral Processing

2016年2月25日It is capable of crushing potash, salt, mica, limestone, gypsum, coal, or any similar soft material not exceeding 4 on the Mohs scale of hardness. Hammer Mill Capacity Table Hammer Crusher The Jeffrey Miracle Hammer Crushe r is designed for the reduction of large pieces and large capacities of limestone, shale, slag, and cement rock.

Ball mill Sandrock Mining

A ball mill can divide into 2 types, wet ball mill, and dry ball mill. Ball mill is a mineral processing machine for milling the materials into powders after they are crushed. It is widely applied to the production of cement, silicate

Ball Mill Working Principle And Main Parts GitHub Pages

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

SSR Mill (Svedala Rubber Roller mill) Wet or dry Overflow and grate discharge Light and fabricated construction Ready assembled on steel frame Easy to move Limited in size (max. diameter 2.4 m) Vertimill ® (Metso Minerals) Wet grinding only Top or bottom feed Grinding by attrition/abrasion Primary or regrinding mill

ball mill, ball grinding mill, ball mill machine Desen Machinery

Materials out of crusher need to go into Ball Mill for further grinding. It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry. The ore grinding methods