Design And Development Of Noiseless Grinding Machine

en/design and development of noiseless grinding

Contribute to dinglei2022/en development by creating an account on GitHub.

sbm design and development of noiseless grinding

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

(PDF) Development of an Improved Domestic Grinding

2018年4月3日Domestic grinding machine 2.1 Design analysis Mass of the hopper = Density of mild steel X volume of hopper. M = ρ x V Volume

(PDF) Development of Desktop Multipurpose Grinding

2015年12月31日For the concept to become a reality, it is necessary that the machine tool can be easily assembled and disassembled by an end

Design and Development of Rice Milling and Grinding Machine

2016年8月31日Design and Development of Rice Milling and Grinding Machine. The main objective of the study is to design and construct a prototype of a limestone huller with

design and development of noiseless grinding machine

Grinding and Grinding Machines by,In this respect the origin and development of the grinding machine was very much,and in 1868 the design for such a machine.

design and development of noiseless grinding machine

hofler hoefler highway machine hmc grinding 2 Grinding Bevel Gears on Cylindrical Gear Grinding Machines,"Undergrinding" is defined and special designs for noiseless gears

Design And Development Of Noiseless Grinding Machine

2019年1月23日Design And Development Of Rice Milling And Grinding. Advances in Engineering Design Technology 1(1) 2019 pp. 49-64 49 Design and Development of a

design and development of noiseless grinding machine

2022年12月27日Grinding mill machine, operation, working principle, parameter design and development of noiseless grinding machine 9.8 (Total 10) 3752 Votes 7504

Design and Development of a High-Speed Precision Internal Grinding

2022年12月27日In order to meet the P2-grade bearing grinding requirements, we designed a high-speed internal grinding machine to be used for grinding bearing raceways and inner circles. The machine has a T-type layout and a four-axis numerical control linkage. It is supported by hydrostatic pressure and driven directly by a torque

Design and Development of a High-Speed Precision Internal Grinding

2022年12月27日By using this grinding machine and grinding technology,we sought to achieve precision and load-carrying capacity times of 3000 h for ceramic ball bearings and 2000 h for steel ball bearings.

Design and Development of Rice Milling and Grinding

consequences 3.) Constructing an experimental design that represents all the elements, conditions, and relations of the consequences. 4.) Conducting the experiment . Description of the Rice Huller and Grinder. Figure 1 shows the final design of the Rice Huller and Grinder. It is 23.5 inches long, 21 inches wide and 43 inches tall. The machine

Machines Free Full-Text Research on Generating Gear Grinding

2022年12月12日Concerning the study of tooth profile modification, Shih et al. [8,9,10] represented the motion of each axis of a five-axis gear grinding machine as a fourth-order polynomial function, and they established the sensitivity matrix of the polynomial coefficients.By adjusting the polynomial coefficients, the machined tooth flank could

Design and Development of Rice Milling and Grinding Machine

2016年8月31日The main objective of the study is to design and construct a prototype of a limestone huller with limestone grinder. Experimental research approach is used in this study. It is an attempt by the researcher to maintain control over

design and development of noiseless grinding machine

Grinding and Grinding Machines by,In this respect the origin and development of the grinding machine was very much,and in 1868 the design for such a machine.

Design And Development Of Noiseless Grinding Machine

2022年1月7日bending machine methods. Design concept To develop a laboratory grinding/polishing machine using the following components; angle-bars, mild steel plate, electric motor (1 HP), shaft (25 mm), belt, pulley, coupling, side pulley disc (250 mm). The laboratory grinding/polishing machine body is made of angle bar. The machine

mplete working model of grinder mills of stone

2019年8月4日Design and development of noiseless grinding machine. Grinding mill machine, operation, working principle, parameter design and development of noiseless grinding machine (Total 10) 3752 Votes 7504 Comments Give e-mail to and development of noiseless wet ball mill machine.

Design And Development Of Noiseless Grinding Machine

2019年1月23日Design And Development Of Rice Milling And Grinding. Advances in Engineering Design Technology 1(1) 2019 pp. 49-64 49 Design and Development of a Hand Operated Grinding Machine Erameh Andrew Aa and Adingwupu Anthony Cb a,bDepartment of Mechanical Engineering, College of Engineering, Igbinedion University,

(PDF) Development of an Improved Domestic

2018年4月3日The grinding mechanism in the design is the burr plate (Kareem and Akinode, 2018). This method also uses a worm gear (auger) to initially crack the maize and transfer it to the burr plates...

On micro flank geometric topography design for spiral bevel and

Where, Table 1 shows the gear blank design data for tooth flank grinding. Table 2 shows the machine settings. Table 3 shows the tool parameters. These data can be perform the data-driven tooth flank grinding simulation and modeling for output tooth flank points [59]. To this end, the macro geometric topography is determined for spiral bevel gears.

Development of a Laboratory Metallographic Grinding/Polishing Machine

The result obtained from the developed laboratory grinding/polishing machine showed a metallic specimen that was well ground and well-polished to mirror-like form for further metallographic examination and is recommended for the end users and the metallography industry. This study centered on the development of a laboratory metallographic

Gtari Grinding Stone

Design And Development Of Noiseless Grinding Machine . A work was carried out on the design and construction of a motorized grain milling machine. The machine was designed using auto-CAD, version 2012 and constructed. 65t Bituminous Coal Mill . Coal mill is the main equipment in cement plant, which is used for drying and grinding of coal.

Design and Development of a High-Speed Precision Internal Grinding

2022年12月27日In order to meet the P2-grade bearing grinding requirements, we designed a high-speed internal grinding machine to be used for grinding bearing raceways and inner circles. The machine has a T-type layout and a four-axis numerical control linkage. It is supported by hydrostatic pressure and driven directly by a torque

Design and Development of a High-Speed Precision Internal Grinding

2022年12月27日By using this grinding machine and grinding technology,we sought to achieve precision and load-carrying capacity times of 3000 h for ceramic ball bearings and 2000 h for steel ball bearings.

(PDF) Development of an Improved Domestic

2018年4月3日The grinding mechanism in the design is the burr plate (Kareem and Akinode, 2018). This method also uses a worm gear (auger) to initially crack the maize and transfer it to the burr plates...

Machines Free Full-Text Research on Generating Gear Grinding

2022年12月12日Concerning the study of tooth profile modification, Shih et al. [8,9,10] represented the motion of each axis of a five-axis gear grinding machine as a fourth-order polynomial function, and they established the sensitivity matrix of the polynomial coefficients.By adjusting the polynomial coefficients, the machined tooth flank could

design and development of noiseless grinding machine

A grinding machine often shortened to grinder is one of power tools or machine tools used for grinding it is a type of machining using an abrasive wheel as the cutting toolEach grain of abrasive on the wheel s surface cuts a small chip from the workpiece via shear deformation Grinding is used to finish workpieces that must show high surface quality eg

design and development of noiseless grinding machine

Grinding and Grinding Machines by,In this respect the origin and development of the grinding machine was very much,and in 1868 the design for such a machine.

Design And Development Of Noiseless Grinding Machine

2022年1月7日bending machine methods. Design concept To develop a laboratory grinding/polishing machine using the following components; angle-bars, mild steel plate, electric motor (1 HP), shaft (25 mm), belt, pulley, coupling, side pulley disc (250 mm). The laboratory grinding/polishing machine body is made of angle bar. The machine

Design And Development Of Noiseless Grinding Machine

2019年1月23日Design and Development of Integrated Melon Design and Development of Integrated Melon Processing Machine Onwuka, Osinachi Stanley* Nwankwojike, Bethrand Nduka Department of Mechanical Engineering, Micheal Okpara University of Agriculture, Umudike P. M. B. 7267, Umuahia Abstract An integrated

sun design and development of noiseless grinding machine

sun design and development of noiseless grinding machine. Our company is committed to building crushing, industrial grinding, ore processing and green building materials, and provides intelligent solutions and mature supporting products.The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing

Design and Development of Rice Milling and Grinding

consequences 3.) Constructing an experimental design that represents all the elements, conditions, and relations of the consequences. 4.) Conducting the experiment . Description of the Rice Huller and Grinder. Figure 1 shows the final design of the Rice Huller and Grinder. It is 23.5 inches long, 21 inches wide and 43 inches tall. The machine

Development of a Laboratory Metallographic Grinding/Polishing Machine

The result obtained from the developed laboratory grinding/polishing machine showed a metallic specimen that was well ground and well-polished to mirror-like form for further metallographic examination and is recommended for the end users and the metallography industry. This study centered on the development of a laboratory metallographic

design and development of noiseless grinding machine

hofler hoefler highway machine hmc grinding 2 Grinding Bevel Gears on Cylindrical Gear Grinding Machines,"Undergrinding" is defined and special designs for noiseless gears are described,to Dr- Ing Hansjörg Geiser, head

and development of noiseless grinding machine scholarly articles

Development of a 3-axis Parallel Kinematic Machine for Milling Wood Material Part 1: Design. Elmas Aşkar Ayyıldız a and Mustafa Ayyıldız b, * A 3-axis parallel kinematic machine tool and advanced control system with programming in G-code for the milling of material are described in detail.

- 锌的化合物及其性质

- 石家庄建筑垃圾

- Circular Flow Vinrating Screens Manufacturer Nate Query Equipment

- 广东中山溶渣鄂式破碎设备

- 村民挖山上矿石要什么手续

- 破碎机石卖

- 石家生产机制沙厂

- 垃圾处理厂设备

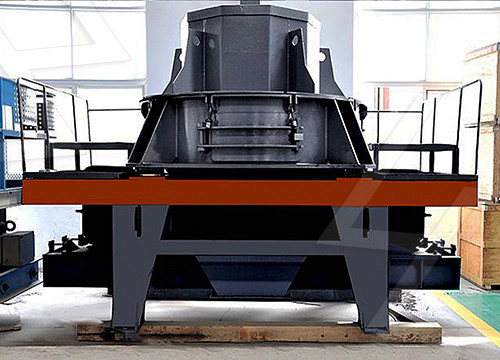

- 细碎vsi7611制砂机

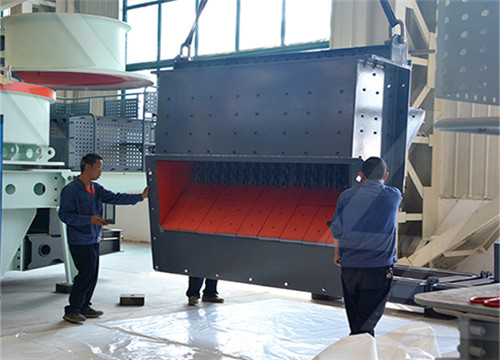

- The Hot Selling Heavy Duty Concrete Vibrating Screen

- 水冲石英石奇石图片

- 山东瓷石矿价格

- 反击式破碎机 PF-A1010

- Drawings Of 400x 600 Stone Crushing Equipment Plant

- 小型露采石场安全生产应急救援预案