Cement Plant Equipment List Mill Tyres Grinding In Situ

Grinding Mill Grinding Equipment Cement Mill

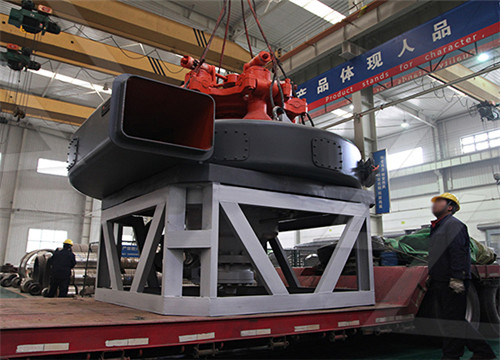

Cement vertical mill is a grinding equipment which emerges grinding, drying, powder separating and conveying into a single. It is widely used in the cement plant and electric power industry because of its high

Cement Grinding Unit Cement Grinding Plant

The cement grinding machine includes cement vertical mill, cement ball mill, cement roller press, cement seperator, conveyor and other cement equipment. We can provide scheme design for free according to the

Cement Equipment, Cement Plant Equipment Cement Plant

cement equipment for clinker plant mainly include cement kiln, preheater, and other cement plant equipment, to ensure the smooth operation of equipment and

进一步探索

What Equipment is Used for Cement Manufacturing?Typical cement manufacturing process flow diagram [4]. 根据热度为您推荐•反馈

Vertical Roller Mill Operation in Cement Plant

The Material Layer of The MillThe Vibration of The MillThe Grinding Pressure of The MillThe Gas Temperature at The Discharging PortThe Air Volume in The MillThe Hot Gas from The Kiln

The grinding pressure is one of the key factors that have a great impact on the yield and quality of products. The grinding pressure of the mill should be adjusted according to the fed quantity, the particle size, and the grindability of the material. It must be well controlled to maintain the thickness of the material layer, reduce the vibration o...

Cement Mill Cement Grinding Machine AGICO Cement

AGICO offers EPC cement projects and different kinds of equipment needed for cement plant, such as a series of cement mills: cement ball mill, rod mill, cement vertical mill,

Cement Manufacturing Equipment AGICO Cement Plant

AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher. Jaw Crushers Jaw crushers are popular size reduction

Cement Plants Cement Plant Equipment, Rotary Kiln

50 TPD-1000 TPD. Cement Plants- with Vertical Shaft Kilns. 50 TPD-300 TPD. Cement Plants- with Rotary Kilns. 200 TPD-1000 TPD. Individual equipment and components

背靠华润渠道的中药OTC龙头——华润三九 【公司概况】

【公司概况】 华润三九医药股份有限公司成立于1999年3月,注册地址位于广东省深圳市龙华区,公司于2000年3月上市。华润三九主要从事医药产品的研发、生产、销售及相关健康

广东省区县工业百强出炉!宝安南山龙岗龙华光明上榜十

宝安南山龙岗龙华光明上榜十. 近日,赛迪顾问广东分支机构正式发布《2022广东省区县工业百强研究》。. 深圳市宝安区、南山区、龙岗区、龙华区、光明区上榜评估结果名单

Premium solutions for the cement industry

Ball mill for cement grinding EXCEL™ premium trunnion-supported mill parts For new cement plants, our process expertise and product portfolio deliver plants with the minimum environmental footprint. And what is good for the environment can also be good for profitability, as energy efficiency coincides with minimising the cost of fuel and

Volume 3, Issue 5, November 2013 Study of Processing and

Ball mill is used in cement industry. After the dry chamber material enters the 1st grinding chamber. 1stgrinding chamber: The chamber allows grinding of the harder limestone that is more common than chalk. A ball mill consists of a horizontal cylinder that rotates on its axis.

Cement mill Wikipedia

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. https://en.wikipedia/wiki/Concrete_grinder

Grinding Mill Grinding Equipment Cement Mill AGICO

Cement vertical mill is a grinding equipment which emerges grinding, drying, powder separating and conveying into a single. It is widely used in the cement plant and electric power industry because of its high efficiency, energy-saving and stable output.

Cement Euipment Overview Cement Making Machines Cement Plant

2019年9月27日Cement mill is another necessary cement equipment of the cement plant. After raw material crushing, cement mill plays vital role in the further cement manufacturing process. Cement ball mill, vertical cement mill, and cement roller press are common types of cement grinding plant. cement ball mill. Cement mill has two

Vertical Roller Mill Operation in Cement Plant

The cement rotary kiln. When operating the vertical roller mill, the operator must control the inlet and outlet air valves to make the air volume of the system in a balanced state, so as not to affect the air pressure at the back end of the rotary kiln. We are AGICO, a professional cement equipment manufacturer and cement plant contractor.

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement Equipment

Low investment: the vertical raw mill set crushing, drying, grinding, grading transportation in one, simple system, compact layout, less space, it also can be arranged in the open air, save a lot of investment costs. Low operation cost: small energy consumption and less damage reduce the running cost. Environment protection and clean: small vibration, low

HardfacingRebuilding Ecorporates

Hardfacing, also known as hard surfacing, is the application of buildup or wear-resistant weld metals to a part's surface by means of welding or joining. Most worn parts don't fail from a single mode of wear, such as impact, but from a combination of modes, such as abrasion and impact. For example, vertical mill grinding rollers are usually

Cement Milll Separator Cyclone Air Separator in Cement Plant

Product Name: cement mill cyclone air separators Capacity: 10 250 TPD Condition: brand new. Airflow: 16000 240000 m3/h SEND INQUIRY Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants.

Wear protection solutions cut cement plant downtime

2023年1月23日This article outlines how the Castolin Eutectic wear protection solutions can make a major contribution to uptime and productivity in four main areas: the vertical roller mill (VRM), roller press rollers, kiln tyres and fan refurbishment. VRM fast response and extended life expectancy Castolin Eutectic Home page News

Ball Mill for Cement Grinding Process cementmillequipment

Cement Ball Mill Structure. When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed. The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc.); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of

Cement Seperator Improves Cement Grinding System

Separator Cement Seperator Scope of application: In the cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used. As an important part of t Read More Get In Touch Now!

Rod Mill Ball Mill Cement Milll AGICO Cement Equipment

The overflow, end peripheral discharge and center peripheral discharge are the three main types of rod mill, while only the wet overflow type rod mill is usually used as the pre-grinding equipment in the cement plant. In order to make the discharging particle size reach the set standard, the grinding time should be 3-4 minutes, the grinding

Nelson Machinery Int'l SALE LIST of Second-Hand Equipment

This is our page listing all of the New surplus equipment for cement manufacturing plants that we currently have for sale. Other good used second hand equipment is also listed on this page. 8' X 16' Ball Mills, Dry Grinding, 320kW 50Hz (4 units) 2.2m X 6m FLS Tirax Coal Mill, 165kW 50Hz. BALL MILL PARTS. 4.4m X 16.5m Cement Mill Shells

Premium solutions for the cement industry

Ball mill for cement grinding EXCEL™ premium trunnion-supported mill parts For new cement plants, our process expertise and product portfolio deliver plants with the minimum environmental footprint. And what is good for the environment can also be good for profitability, as energy efficiency coincides with minimising the cost of fuel and

Cement mill Wikipedia

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. https://en.wikipedia/wiki/Concrete_grinder

Nelson Mach Sellers of Second-Hand Cement Plant Equipment

This POLYSIUS plant features a POLYCOM High-Pressure Grinding Roll (Roller Press), Static Separator, followed by a 5800kW single chamber ball mill, SEPOL dynamic separator, 2 cement coolers, all anciliaries. 50Hz electrics. For other Grinding Plants go to the full listing in our SALE LIST KOVAKO M-130-D4 SHIPUNLOADER

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor

Cement Milll Separator Cyclone Air Separator in Cement Plant

Product Name: cement mill cyclone air separators Capacity: 10 250 TPD Condition: brand new. Airflow: 16000 240000 m3/h SEND INQUIRY Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants.

11.6 Portland Cement Manufacturing US EPA

1971年8月17日Classification Code (SCC) for portland cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns is 3-05-007. Portland cement accounts for 95 percent of the hydraulic cement production in the United States. The balance of domestic cement production is primarily masonry cement. Both

Cement Seperator Improves Cement Grinding System

Separator Cement Seperator Scope of application: In the cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used. As an important part of t Read More Get In Touch Now!

HardfacingRebuilding Ecorporates

Hardfacing, also known as hard surfacing, is the application of buildup or wear-resistant weld metals to a part's surface by means of welding or joining. Most worn parts don't fail from a single mode of wear, such as impact, but from a combination of modes, such as abrasion and impact. For example, vertical mill grinding rollers are usually

How to Improve Cement Plant Process for Better Cement Quality

In order to improve cement quality of cement plant, we must first control the raw material source of cement plant. For raw materials were supplied by many clinker plants and the sources were complicated. According to the production needs of cement plants, the strength of incoming clinker should be controlled within the range of 28 ~32MPa, and 1

Equipment For Rebuilding Of Tyre Of Insitu Coal Grinding Mill

The rods may require rebuilding after grinding. sale in situ grinding machines of crankshaft coal mining equipment in n.z; Home Grinding Equipment vertical roller mill Cement Mill; Raw Mill; Coal Mill; The comparison of vertical roller mill and ball mill in cement grinding

Nelson Machinery Int'l SALE LIST of Second-Hand Equipment

This is our page listing all of the New surplus equipment for cement manufacturing plants that we currently have for sale. Other good used second hand equipment is also listed on this page. 8' X 16' Ball Mills, Dry Grinding, 320kW 50Hz (4 units) 2.2m X 6m FLS Tirax Coal Mill, 165kW 50Hz. BALL MILL PARTS. 4.4m X 16.5m Cement Mill Shells

Cement manufacturing components of a cement plant Understanding Cement

Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions. This blended raw material is called the 'raw feed' or 'kiln feed' and is heated in a rotary kiln where it reaches a temperature of about 1400 C to 1500 C.

Sugar Plant Mill Machinery PartsEquipment Tyres

Manufacturer of Sugar Plant Mill Machinery PartsEquipment Tyres, 100 TPD Pinion Gears, Kiln Pinion Gears and Girth Gear offered by Shape Machine Tools Private Limited, Ghaziabad, Uttar Pradesh. Rotary Coolers, Dryers for cement plants, power plants, steel plants, mineral grindingprocessing plants etc. Crusher mills, crush rolls