Kilograms Capacity Jaw Crusher

CJ411 Single-Toggle Jaw Crusher For High

Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and production capacity. Wider intake opening enables

CJ613 Single-Toggle Jaw Crusher With A Heavy

Welded frame ensures equal strength in all directions, and excellent durability. Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and

Capacities and performance characteristics of jaw crushers

for the effect of feed size on jaw crusher capacity Capacity, th-I Size of Rose and feed, m Hersam, W, English, WR WaIWR 0.076 0.102a 0.271 0.368 0.74 0.051 1923). For

Estimate Jaw Crusher Capacity Mineral Processing

2016年2月17日Estimate Jaw Crusher Capacity jaw crusher production capacity Example capacity calculation of a 10″ x 20″ (250 mm x 500

Jaw Crushers Parker Plant

With a range of drive options and six jaw sizes to choose from RockRanger RQ RockRanger RE 1 Feed Hopper Externally reinforced heavy duty steel plate hopper. (RE1180 folds down for travelling). 2 Feeder Grizzly

Jaw Crushers Heavy Duty Finlay

The Finlay® J-1480 tracked mobile crusher incorporates the Finlay® Jaques JW55 single toggle jaw which boasts a throughput capacity up to 750mtph depending on application

Industrial Solutions Jaw crushers ThyssenKrupp

The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw crusher with the same feed opening. The diversity of feed mate

Mobile Jaw Crusher RUBBLE MASTER

Mobile Jaw Crusher Capacity 385 TPH Inlet opening 43" x 27" Weight 110,231 lbs Imperial / metric Meet us at ConExpo 2023 Silver Lot March 14-18 learn more A Mobile Jaw Crusher Taking the Brunt The RM

KPI-JCI PDF Catalogs Technical Documentation

Innovative crusher design produces MODEL Jaw Opening Weight Capacity Up Tounmatched capacity. (in / mm) (Ibs / kg) (tph / mpth) Fly-wheel design reduces 2640 26 / 660 29,500 / 13,393 240 / 218

® C Series™ jaw crushers Proven reliability and

C Series jaw crushers have a strong pinned and bolted, non-welded frame Crusher throughput capacity, scalped feed material 12 Crusher throughput capacity, non-scalped material 14 Aftermarket parts and services 16 Proven case studies 18. Basic crusher weight *) 7 650 kg 16 870 lbs 10 150 kg

CJ411 Single-Toggle Jaw Crusher For High

Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and production capacity. Wider intake opening enables the equipment to handle a larger feed. Technical data. Weight. 28,000 kg

CJ815 Single-Toggle Jaw Crushers For High Production

CJ815 single-toggle jaw crusher is engineered for even the toughest applications thanks to its heavy-duty design. Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and production capacity; Technical data; Weight: 72,500 kg (160,000 lb) Feed opening: 1,500 x 1,300 mm (59 x 51 in.) Feed size: 1,170

Product datasheet Jaw Gyratory Crusher BK 54-67 Pro

Total weight5 Approx. 175,000 kg Heaviest piece for transportation6 Approx. 46,000 kg Heaviest piece for maintenance7 Approx. 34,000 kg 1. Crusher capacity calculated based on a feed material bulk density of 1.6 metric t/m³. Actual values depend on feed material characteristics and crusher configuration. All data

Jaw Crushers Heavy Duty Finlay

LJ-130 Hybrid. The Finlay® LJ-130 hybrid mobile jaw crusher is the largest mobile jaw crusher in our range and has been developed for large-scale quarry and mining operations.The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies. The machine features a robust 1300 x 1000mm (51

Fine Jaw Crushers

HSC550 Jaw Crusher a proven trouble-free performer, It delivers greater throughput at 180 kg/hr, with a higher reduction ratio of 50:1 producing a consistent 2 mm product size. You also have the flexibility to collect crushed material in a drawer with a capacity of two or five litres, or, in the case of large samples, to work

Mobile Jaw Crusher RUBBLE MASTER

43" x 27" mobile jaw crusher ideal for heavy-duty primary crushingconcrete recycling applications. It features a large hopper and magnet for steel. Jaw Crusher Capacity 350 tph 385 TPH: RM HS3500M;

Industrial Solutions Jaw crushers ThyssenKrupp

The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw crusher with the same feed opening. The diversity of feed mate [mm] [kg/unit] [kW] [r.p.m.] 4 Jaw crushers 5. Throughput rates and grain size distribution curves The rates are based on theoretical calculations that have

® C Series™ jaw crushers Metso Outotec

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that

CEN00175-04 BR300JG-1E0 MOBILE CRUSHER Komatsu

34000 kg 74,960 lb The newly designed Komatsu BR380JG-1E0 mobile crusher looks simple but is very powerful. Komatsu’s original large-capacity jaw crusher and the most advanced control systems have considerably increased its output capacity, making it easy to manage large workloads.

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

How to Calculate and Solve for Capacity of Jaw Crusher Mineral

2021年11月21日Let’s solve an example; Find the width of crusher when the capacity of jaw crushers is 4, the gape size is 2 and the closed single setting of jaw crusher is 8. This implies that; C JC = Capacity of Jaw Crushers = 4. G = Gape Size = 2. CSS = Closed Single Setting of Jaw Crushers = 8. W = CJC x CSS / G.

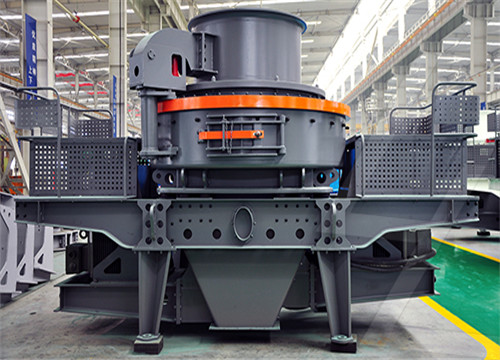

Stone Crushing Machine 315kw Cone Crusher Iron Ore Single

The new crusher structure, optimized laminated crushing chamber type and fully intelligent automatic control system make GP series single-cylinder hydraulic cone crusher have the performance characteristics that traditional cone crusher does not have. It can be widely used in medium crushing, fine crushing and ultra-fine crushing operations.

Jaw Crusher ScienceDirect

2016年1月1日The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. The crusher was next used to crush a second mineral of compressive strength 55 MN/m 2 at 5 kg/s. The feed size of the second mineral was –55 + 40 mm and yielded a

® C Series™ jaw crushers Proven reliability and

C Series jaw crushers have a strong pinned and bolted, non-welded frame Crusher throughput capacity, scalped feed material 12 Crusher throughput capacity, non-scalped material 14 Aftermarket parts and services 16 Proven case studies 18. Basic crusher weight *) 7 650 kg 16 870 lbs 10 150 kg

CJ411 Single-Toggle Jaw Crusher For High

Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and production capacity. Wider intake opening enables the equipment to handle a larger feed. Technical data. Weight. 28,000 kg

CJ815 Single-Toggle Jaw Crushers For High Production

CJ815 single-toggle jaw crusher is engineered for even the toughest applications thanks to its heavy-duty design. Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and production capacity; Technical data; Weight: 72,500 kg (160,000 lb) Feed opening: 1,500 x 1,300 mm (59 x 51 in.) Feed size: 1,170

Product datasheet Jaw Gyratory Crusher BK 54-67 Pro

Total weight5 Approx. 175,000 kg Heaviest piece for transportation6 Approx. 46,000 kg Heaviest piece for maintenance7 Approx. 34,000 kg 1. Crusher capacity calculated based on a feed material bulk density of 1.6 metric t/m³. Actual values depend on feed material characteristics and crusher configuration. All data

Jaw Crushers Heavy Duty Finlay

The Finlay® J-1480 tracked mobile crusher incorporates the Finlay® Jaques JW55 single toggle jaw which boasts a throughput capacity up to 750mtph depending on application and material. The machine has hydrostatic drive which offers reversible operation for clearing blockages and demolition applications.

Fine Jaw Crushers

HSC550 Jaw Crusher a proven trouble-free performer, It delivers greater throughput at 180 kg/hr, with a higher reduction ratio of 50:1 producing a consistent 2 mm product size. You also have the flexibility to collect crushed material in a drawer with a capacity of two or five litres, or, in the case of large samples, to work

Mobile Jaw Crusher RUBBLE MASTER

43" x 27" mobile jaw crusher ideal for heavy-duty primary crushingconcrete recycling applications. It features a large hopper and magnet for steel. Jaw Crusher Capacity 350 tph 385 TPH: RM HS3500M;

® C Series™ jaw crushers Metso Outotec

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

CEN00175-04 BR300JG-1E0 MOBILE CRUSHER Komatsu

34000 kg 74,960 lb The newly designed Komatsu BR380JG-1E0 mobile crusher looks simple but is very powerful. Komatsu’s original large-capacity jaw crusher and the most advanced control systems have considerably increased its output capacity, making it easy to manage large workloads.

Portable Jaw Crushers MEKA Concrete Plants

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use the Call Back option if you would like to be contacted by our sales team.

Jaw Crusher ScienceDirect

2016年1月1日Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are manufactured by Locomo, (Metso) and others. The Metso crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors. Table 4.1. Jaw

How to Calculate and Solve for Capacity of Jaw Crusher Mineral

2021年11月21日Let’s solve an example; Find the width of crusher when the capacity of jaw crushers is 4, the gape size is 2 and the closed single setting of jaw crusher is 8. This implies that; C JC = Capacity of Jaw Crushers = 4. G = Gape Size = 2. CSS = Closed Single Setting of Jaw Crushers = 8. W = CJC x CSS / G.

BR380JG-1E0 Crushers Komatsu Australia Komatsu Australia

380 kg/cm 2: Maximum travel speed: 3 km/h: System oil flow : Travel: 2 x 160 ltr/min: Crusher: High Performance Jaw The KCJ4222 large-capacity jaw crusher guarantees maximum crushing capacity in this class along with ease of maintenance. In addition, Komatsu's locking cylinder mechanism allows you to change the discharge clearance