Working Operation Of A Crushing Unit

Crushers: A Brief Guide to Crushers and Crushing Operations

2023年3月6日Essentially, there are four types of crushing operations: shearing, compression, abrasion, and impact. Shearing is a cutting action that cleaves a workpiece

进一步探索

(PDF) Crushing and Screening Handbook Academia.eduRock Crushing Rule of Thumb Mineral ProcessingMetal根据热度为您推荐•反馈

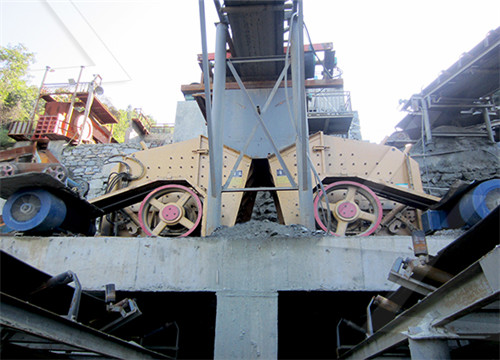

How does the operation of crusher plants work?

2022年12月23日The basic operation of most crusher plants include sorting, crushing, and sizing the material. Once these steps are completed, the material is ready for

Guidelines for Management Crushing and Screening

C. Refer to “Guideline for Safe Operation of Mobile Plant in Surface Mines and Quarries.” 2.0 PRIMARY STOCKPILES A. Live stockpile accident are all too common. The limits of

Rock quarry crushing operations HD YouTube

2021年12月14日Rock quarry crushing operations HD. Check out this fully operational rock crushing operation making gravel. I show you all the equipment in operation

Rock Crushing Process in Mining Mineral Processing

2015年7月18日Let’s follow a rock through a crushing cycle to see what variables will have to be controlled. First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow

Hammer Mill Operating Principle Mineral ProcessingMetallurgy

2016年2月25日Dry crushing of ores for dry or wet concentration. Concrete recycling 3″, or 4″ and under, in one operation, the one unit doing the work ordinarily done by two or

Systems / Unit Operations Crushing / grinding HSE

Measures to prevent, control or mitigate major accidents involving impurities effects of Crushing / Grinding are: Prevention Operating Procedures Control Relief Systems

Performance Monitoring for a Crushing Plant Cmms

Crushing plant availability can be assessed as well. The availability report calculates time periods for each crushing unit during which the unit is running. By storing the

training.gov.au RIIPRO201D Conduct crushing operations

This unit develops a participant’s skills and knowledge required to conduct crushing operations in Coal and Metalliferous mining and Extractive. This unit is appropriate for

Crushers: A Brief Guide to Crushers and Crushing Operations

2023年3月6日Types of Crushing Operation. Essentially, there are four types of crushing operations: shearing, compression, abrasion, and impact. Shearing is a cutting action that cleaves a workpiece between the edges of two surfaces. Compression involves squeezing with a workpiece between two opposing surfaces with increasing pressure until it breaks.

How does the operation of crusher plants work?

2022年12月23日The basic operation of most crusher plants include sorting, crushing, and sizing the material. Once these steps are completed, the material is ready for shipment or further processing. Crusher

Guidelines for Management Crushing and Screening final feb10

C. Refer to “Guideline for Safe Operation of Mobile Plant in Surface Mines and Quarries.” 2.0 PRIMARY STOCKPILES A. Live stockpile accident are all too common. The limits of safe tipping areas change as material is loaded out, and operating rules and procedures must fully account for this.

Measuring Work Efficiency of the Rock-Crushing Operation of

2016年12月6日In this , we measure a work efficiency of the rock crushing operation of the underwater robot hydraulic system and presents effective parameters for the maximum work efficiency. Because of the power resource is not enough to work in underwater environment for a long time, it is important to know the work efficiency of the

Hammer Mill Operating Principle Mineral Processing

2016年2月25日Hammermills are capable of accomplishing: reductions very much greater than any other type of crushing equipment. It is possible, though not always economical, to make reductions as high as 20:1 in open circuit, and

Loading and Haulage Equipment Selection for Optimum

at no time during the loading and haulage operation await other trucks, unless there is a problem at the crushing unit. The optimal determination of the number of trucks that will be effective for the continuous operation of any selected excavator to yield the desired output of the company forms the basis of this research.

training.gov.au RIIPRO201D Conduct crushing operations

This unit develops a participant’s skills and knowledge required to conduct crushing operations in Coal and Metalliferous mining and Extractive. This unit is appropriate for those working in operational roles. No licensing, legislative or certification requirements apply to this unit at the time of publication. Unit Sector. Coal mining

SAG Mill Grinding Circuit Design Mineral

2016年6月6日Adding pebble crushing as a unit operation is the most common variant to closed-circuit AG/SAG milling (instead of direct recycle of oversize material ). Simple repeatable work index tests are usually

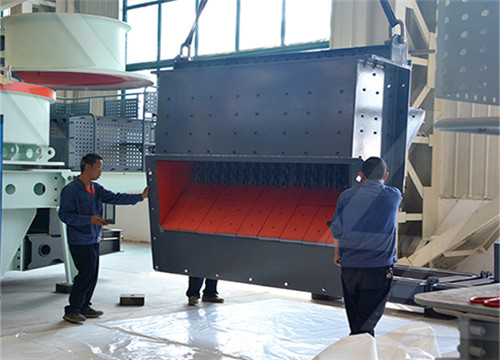

Shut down management Plant Maintenance

Crushing and Screening plant Transfer house 1 Unloading plant Unloading unit no 2 Unloading unit no 1 4.2 Sequencing machines with eight-hour shift: List out the critical defects of each machine. Spilt up the maintenance work or activity of each machine in smallest part. List the resources required for each work.

Gyratory Crusher l Introduce, Working Principle

The crushing machine continuous working, which can make full use of the output energy of the driving motor. And it can make use of the strong kinetic energy of debris splashing produced in the process of rock crushing to

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

HSE Quarries Safe operation and use of mobile jaw crushers

The operation of the crusher catches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar). Struck by...

Cone crusher basics in 4 minutes — SRP

This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing. That’s what you’ll find here!

Gyratory Crusher an overview ScienceDirect Topics

Crushing takes place by the impact of material pieces with the high speed moving hammers and by contact with breaker plates. A cylindrical grating or screen is placed beneath the rotor. Materials are reduced to a size small enough to pass through the openings of the grating or screen.

Crushers: A Brief Guide to Crushers and Crushing Operations

2023年3月6日Types of Crushing Operation. Essentially, there are four types of crushing operations: shearing, compression, abrasion, and impact. Shearing is a cutting action that cleaves a workpiece between the edges of two surfaces. Compression involves squeezing with a workpiece between two opposing surfaces with increasing pressure until it breaks.

How does the operation of crusher plants work?

2022年12月23日The basic operation of most crusher plants include sorting, crushing, and sizing the material. Once these steps are completed, the material is ready for shipment or further processing. Crusher...

Measuring Work Efficiency of the Rock-Crushing Operation of

2016年12月6日In this , we measure a work efficiency of the rock crushing operation of the underwater robot hydraulic system and presents effective parameters for the maximum work efficiency. Because of the power resource is not enough to work in underwater environment for a long time, it is important to know the work efficiency of the

Guidelines for Management Crushing and Screening final feb10

C. Refer to “Guideline for Safe Operation of Mobile Plant in Surface Mines and Quarries.” 2.0 PRIMARY STOCKPILES A. Live stockpile accident are all too common. The limits of safe tipping areas change as material is loaded out, and operating rules and procedures must fully account for this.

Crushing in Mineral Processing

2015年12月26日In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate/surface. Less abrasive and softer rocks or stones are crushed by impact and

Hammer Mill Operating Principle Mineral Processing

2016年2月25日Hammermills are capable of accomplishing: reductions very much greater than any other type of crushing equipment. It is possible, though not always economical, to make reductions as high as 20:1 in open circuit, and

Loading and Haulage Equipment Selection for Optimum

at no time during the loading and haulage operation await other trucks, unless there is a problem at the crushing unit. The optimal determination of the number of trucks that will be effective for the continuous operation of any selected excavator to yield the desired output of the company forms the basis of this research.

training.gov.au RIIPRO201D Conduct crushing operations

This unit develops a participant’s skills and knowledge required to conduct crushing operations in Coal and Metalliferous mining and Extractive. This unit is appropriate for those working in operational roles. No licensing, legislative or certification requirements apply to this unit at the time of publication. Unit Sector. Coal mining

Shut down management Plant Maintenance

Crushing and Screening plant Transfer house 1 Unloading plant Unloading unit no 2 Unloading unit no 1 4.2 Sequencing machines with eight-hour shift: List out the critical defects of each machine. Spilt up the maintenance work or activity of each machine in smallest part. List the resources required for each work.

Unit Operations in Food Processing R. L. Earle NZIFST

In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the other reciprocating, so as to work the material down into a narrower and narrower space, crushing it as it goes. The gyrator crusher consists

Gyratory Crusher l Introduce, Working Principle

The crushing machine continuous working, which can make full use of the output energy of the driving motor. And it can make use of the strong kinetic energy of debris splashing produced in the process of rock crushing to

HSE Quarries Safe operation and use of mobile jaw crushers

The operation of the crusher catches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar). Struck by...

DESIGN AND CONSTRUCTION OF SUGARCANE JUICE

coupled with the shaft in the crushing chamber and the pinion gears were used on both sides of the rollers to connect to a chain drive. IV. MACHINE DESCRIPTIONOPERATION The crushing unit is made of two rollers which are 134 mm thick diameter and length of 26.5 mm, with crushing section of the roller of 17.8 mm length and

Principles and practices of small and medium scale fruit juice

These systems operate in parallel to insure continuous operation and can reduce or eliminate the need for filter aid; a purchase and disposal expense. 6.1.7 Deaeration. In the operations described crushing, comminution, pressing, shaker separation, centrifugation and filtration, the fruit and juice are subjected to considerable aeration.