Iron Ore Crushing Plant Banda?Aceh?

The six main steps of iron ore processing Multotec

Screening. We recommend that you begin by screening the iron ore to separate fine

Magnetic Properties of Manggamat, Aceh Selatan Iron Ore

2013年5月10日The magnetic mineral identification of the iron ore from Manggamat, Aceh Selatan, Indonesia has been done. Universitas Syiah Kuala, Darussalam, Banda

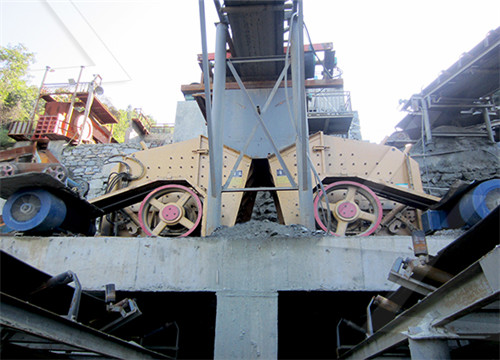

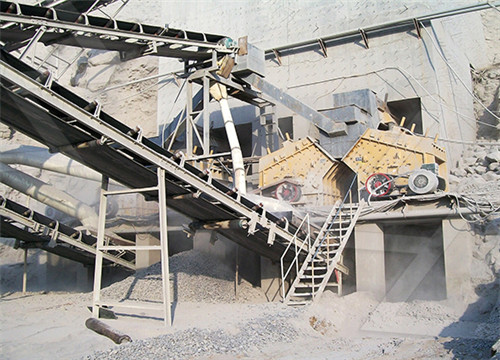

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日Bayan Obo is rich in iron, rare earth, niobium and other metals. Iron is one of the main minerals here. Iron is harder than most stones. According to the traditional

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After

BIG AND HARD BOULDER CRUSHED BY 1600 TPH

2022年2月15日big and hard boulder crushed by 1600 tph kobelco gyratory cone crusher ii iron ore crushing plant ii1600 tph kobelco gyratory cone crusher1 iron ore crushing...

MULTIPLE VIEW OF IRON ORE MINING AND

2022年4月14日MULTIPLE VIEW OF IRON ORE MINING AND PROCESSING, CONTINUOUS FINES IRON ORE DUMPING IN CRUSHING PLANT YouTube MULTIPLE VIEW OF IRON ORE

Beneficiation of Iron Ores IspatGuru

2014年4月3日Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron,

Open Access proceedings Journal of Physics:

2022年8月25日The iron ore was collected from the Lampakuk mining area, Aceh Besar. The iron ore was washed and dried around 4 hours in the air. Then, to have fine

Crushing Plant an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was

Beneficiation Plants and Pelletizing Plants for Utilizing Low

1. Iron ore supply and demand outline 1.1 Types of iron ore Iron ores can be classified in different ways. The most important has to do with the iron content. In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low grade.

The six main steps of iron ore processing Multotec

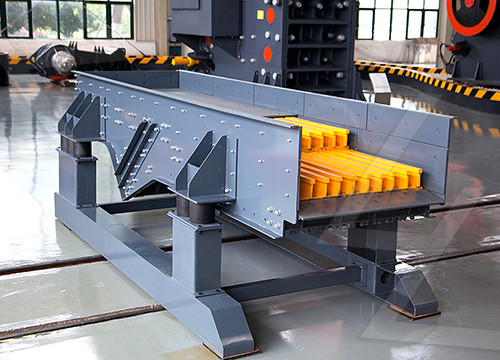

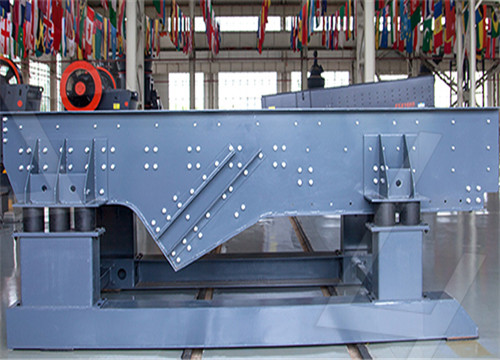

When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles. The large particles are diverted back into the crusher and the fine particles will undergo a spiral gravity separation process. 5. Spiral gravity separation

Crushing Plant FlowsheetDesign-Layout Mineral

2016年3月10日In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work

Magnetic Properties of Manggamat, Aceh Selatan

2013年5月10日Iron Ore Magnetic Properties of Manggamat, Aceh Selatan Iron Ore At: Lampung, Indonesia Authors: Zulkarnain Jalil Faculty of Mathematics and Natural Sciences, Syiah Kuala University...

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

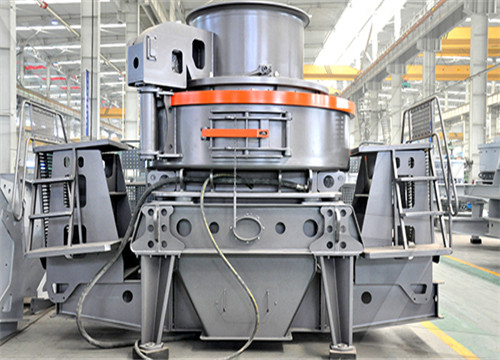

Challenges and opportunities in the iron ore crusher

2019年8月8日Analysis of iron ore crusher. The importance of iron ore crushing process; Before dry selection, the lean iron ore requires millimeter-scale fine crushing by the fine crusher. If the particle size of

Iron Ore Processing,Crushing,Grinding Plant

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

700tph Iron Ore Crushing Plant Eastman Rock Crusher

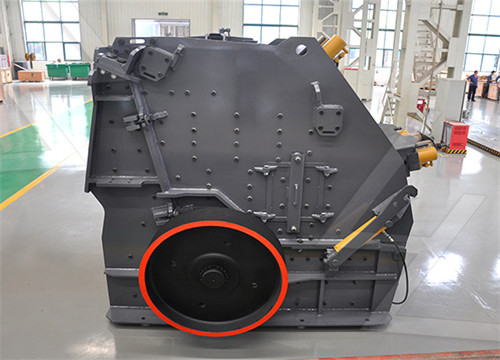

2020年8月24日Bayan Obo is rich in iron, rare earth, niobium and other metals. Iron is one of the main minerals here. Iron is harder than most stones. According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces.

CRUSHING PLANT IS IN OPERATION CONTINUE AT NIGHT, IRON ORE YouTube

2022年6月15日CRUSHING PLANT IS IN OPERATION CONTINUE AT NIGHT, IRON ORE PROCESSING PLANT RUNNING AT NIGHT#technical_info_fe2o3#crusherplant #boulder

Godawari Power and Ispat Limited Iron Ore Crushing

2008 Setting up of Iron Ore Crushing Plant at Gidhali of 12,00,000 TPA capacity. 2009 Iron Ore mining operations started at Ari Dongri, Dist. Kanker. 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation

Crusher Plant MineralAggregate Processing

Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materials. The purpose of the crushing process plant is to obtain

Beneficiation of Iron Ore Mineral Processing

2016年5月24日Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which

Solution-Jiaozuo zhongxin heavy industry

300tph Iron ore crushing plant 300tph limestone crushing plant 350tph pebble crushing plant 150-200tph Aluminum stone crushing production line Related Products XL series spiral sand washing machine ZXC European Type Jaw Crusher Jaw Crusher PC Series Mobile Jaw Crusher Plants Leave a Message Contact Form

Iron processing Ores Britannica

Crushing As-mined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (0.04 inch). The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle size.

The six main steps of iron ore processing Multotec

When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles. The large particles are diverted back into the crusher and the fine particles will undergo a spiral gravity separation process. 5. Spiral gravity separation

Beneficiation Plants and Pelletizing Plants for Utilizing Low

1. Iron ore supply and demand outline 1.1 Types of iron ore Iron ores can be classified in different ways. The most important has to do with the iron content. In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low grade.

Crushing Plant FlowsheetDesign-Layout Mineral

2016年3月10日In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work

Challenges and opportunities in the iron ore crusher

2019年8月8日Analysis of iron ore crusher. The importance of iron ore crushing process; Before dry selection, the lean iron ore requires millimeter-scale fine crushing by the fine crusher. If the particle size of

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Iron Ore Processing,Crushing,Grinding Plant

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日Bayan Obo is rich in iron, rare earth, niobium and other metals. Iron is one of the main minerals here. Iron is harder than most stones. According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces.

Beneficiation of Iron Ore Mineral Processing

2016年5月24日The Iron Ore Process Flowsheet The iron ore beneficiation flowsheet presented is typical of the large tonnage magnetic taconite operations. Multi-parallel circuits are necessary, but for

SNIM Open Pit Iron Ore Mining Mauritania Mining Technology

2021年5月13日Approximately 50% of the 10Mtpa–12Mtpa ore produced is processed at the mining area plants and the remainder at Point Central. SNIM markets several grades: 0mm to 90mm and 8mm to 30mm lump ores, sinter fines and high-phosphorus concentrates. In 2004, SNIM mined 10.7Mt of ore and shipped 11Mt of product, 14.3% more than in 2003.

Godawari Power and Ispat Limited Iron Ore Crushing

2008 Setting up of Iron Ore Crushing Plant at Gidhali of 12,00,000 TPA capacity. 2009 Iron Ore mining operations started at Ari Dongri, Dist. Kanker. 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation

Crushing Plant an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was determined as 12.2 kWh/t. A wet ball mill 1 m × 1 m was

Mining of Iron Ores IspatGuru

2014年3月14日In crushing and washing plants the processing of the ore is carried out. Processing of the ore ranges from simple crushing and screening and separating various size fractions of the ore to the processes that beneficiate or upgrade the

Ore crushing plant, iron ore crushing plant, copper ore crusher,

Attention: If the feeding size is smaller than 115mm, 150mm, 200mm, it can be crushed by the spring cone crusher directly, and avoid the primary stage crushing. Iron ore Crushing and Screening Production Line

Iron Ore Geoscience Australia

2018年12月31日Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4 ). Hematite is an iron oxide mineral. It is non-magnetic and has colour variations ranging from steel silver to reddish brown. Pure hematite contains 69.9% Fe by molecular weight.