Sme Vibrating Screen Process Planning

Simulation of the screening process on a circularly

2011年9月1日Fig. 3a shows that the average velocity has significant periodic variations induced by the vibrating screen deck.At a time of about 1.5 s particulates cover the

(PDF) A dynamic programming model for Reconfigurable

2020年1月1日A dynamic programming model for Reconfigurable Vibrating Screen machine operations planning in a fluctuating market environment January 2020

Linear vibrating screens LinaClass® Schenck Process

The applications are wide-ranging. Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based

Vibrating Screen Working Principle Mineral Processing

IntroductionNamingMechanismApplicationsPurposeCauseUseSpecificationsSafetyOperationAssessmentCriticismsAnalysisExampleAdvantagesConstructionTypesDesign

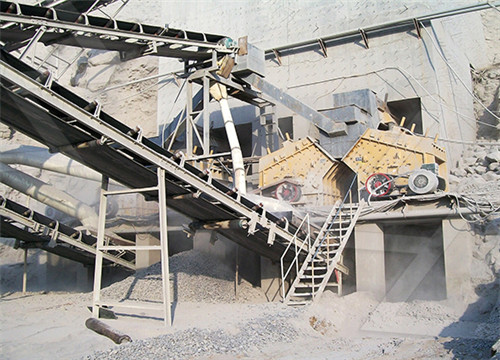

The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame. The frame is mounted on springs. The vibration is generated from an unbalanced flywheel. A very erratic motion is developed when this wheel is rotated. You will find these simple screens in smaller operations and rock qua...

Simulation of the screening process on a circularly

2011年9月1日The screening efficiency is highest when the vibration amplitude, throwing index, and screen deck inclination angle are 3–3.5mm, 2.7 and 15°, respectively. This

Collaborative and Adaptive Process Planning for

• developing a series of innovative and adaptive process planning services to support SMEs to simulate, evaluate, plan and optimise their dynamic and complex manufacturing

Solved with COMSOL Multiphysics 5.1 Vibrating

2 VIBRATING MEMBRANE (1) The values k ij. are derived from the roots of the Bessel functions of the first kind. In . Table 1 the computed results are compared with the results

Separation Engineers, India SME

Metal Powder Vibrating Screening Machines All the Metal Powders whether they are used for manufacturing of Welding Rods, Sintered Components, or for making Alloys, required

Planning the Process for Additive Manufacturing SME

2020年6月4日Starting with the additive machine itself, medical manufacturers must meet numerous requirements for parts that can be safely used for health care applications.

Process model of vibrating screen based on DEM and physics

2022年9月1日This study develops a new process model for vibrating screens by the combination of discrete element method simulation and physics-informed machine learning. First, based on the assumption that the particle passing in a part of a screen is dependent on the local screen and flow conditions, the relationship between the passing flow rate

Simulation of the screening process on a circularly vibrating screen

2011年9月1日Fig. 3a shows that the average velocity has significant periodic variations induced by the vibrating screen deck.At a time of about 1.5 s particulates cover the entire screen and the screening process is in a stable state.The overall average velocity of the particles is stable at 0.373 m/s.. In this work, the screen-deck was divided into six equal

A dynamic programming model for Reconfigurable Vibrating

Screen (RVS) machine is a screening machine designed at the outset to accommodate rapid adjustment of the structural components of the machine in order to quickly adjust the machine mineral

Process model of vibrating screen based on DEM and physics

Vibrating screens are widely used in industry but it is difficult to consider the enormous controlling variables and complicated particle-particle interactions in current screen process models. This study develops a new process model for vibrating screens by the combination of discrete element method simulation and physics-informed machine

(PDF) A dynamic programming model for Reconfigurable Vibrating Screen

2020年1月1日A dynamic programming model for Reconfigurable Vibrating Screen machine operations planning in a fluctuating market environment Authors: Olasumbo Makinde Tshwane University of Technology...

Linear vibrating screens LinaClass® Schenck Process

Linear vibrating screens, which can be specially adapted to the tasks, are critical here to achieving high and consistent quality. Schenck Process already provides linear screens in standard format in a variety of designs. For example as single or multiple-decks.

PROCESS PLANNING SpringerLink

Process planning is a preparatory step before manufacturing, which determines the sequence of operations or processes needed to produce a part or an assembly. This step is more important in job shops, where one-of-a-kind products are made or the same product is made infrequently. The outputs of this step are: route sheet and operations sheet.

Collaborative and Adaptive Process Planning for Sustainable

• developing a series of innovative and adaptive process planning services to support SMEs to simulate, evaluate, plan and optimise their dynamic and complex manufacturing processes and execution systems in collaborative value chains, in a bid to achieve efficiency, cost-effectiveness, robustness, sustainability, smartness and user intervene

Solved with COMSOL Multiphysics 5.1 Vibrating Membrane

2 VIBRATING MEMBRANE (1) The values k ij. are derived from the roots of the Bessel functions of the first kind. In . Table 1 the computed results are compared with the results from Equation 1 . The agreement is very good. The mode shapes for the first six modes are shown in Figure 1 through Figure 6.

What is Manufacturing Process Planning Siemens Software

Manufacturing process planning is an aspect of product lifecycle management (PLM) that helps engineers to author, simulate, and manage manufacturing information while collaborating to align manufacturing plans with product design.

Vibrating Screen, Vibratory Screener, Mining Vibrating Screen

Mineral vibrating screen is an important equipment in mineral processing plant, we should pay attention to its maintenance. Let's see why and how! 2020-02-07 05:02:34

Computer-aided process planning Wikipedia

Computer-aided process planning. Computer-aided process planning ( CAPP) is the use of computer technology to aid in the process planning of a part or product, in manufacturing. CAPP is the link between CAD and CAM in that it provides for the planning of the process to be used in producing a designed part. [1]

AViTEQ: Linear vibrating screen

AViTEQ-Vibrating screen are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker or to provide a feed to a belt conveyor or crusher.Depending on the task, the devices are designed with a robust inlet area with liners (wearing plates) followed by two or three

Process model of vibrating screen based on DEM and physics

2022年9月1日This study develops a new process model for vibrating screens by the combination of discrete element method simulation and physics-informed machine learning. First, based on the assumption that the particle passing in a part of a screen is dependent on the local screen and flow conditions, the relationship between the passing flow rate

Process model of vibrating screen based on DEM and physics

2022年8月1日In the present , the sieving process of elliptically vibrating screen was numerically simulated based on the Discrete Element Method (DEM). The production quality and the processing capacity

Simulation of the screening process on a circularly vibrating screen

2011年9月1日Vibration parameters have significant effects on the circularly vibrating screening process. Too small a vibration amplitude, a throwing index, or a screen-deck inclination angle will cause the accumulation of particles on the deck. But too large values of these parameters will also reduce screening efficiency.

Process model of vibrating screen based on DEM and physics

Vibrating screens are widely used in industry but it is difficult to consider the enormous controlling variables and complicated particle-particle interactions in current screen process models. This study develops a new process model for vibrating screens by the combination of discrete element method simulation and physics-informed machine

A dynamic programming model for Reconfigurable Vibrating

Screen (RVS) machine is a screening machine designed at the outset to accommodate rapid adjustment of the structural components of the machine in order to quickly adjust the machine mineral

PROCESS PLANNING SpringerLink

Process planning is a preparatory step before manufacturing, which determines the sequence of operations or processes needed to produce a part or an assembly. This step is more important in job shops, where one-of-a-kind products are made or the same product is made infrequently. The outputs of this step are: route sheet and operations sheet.

Solved with COMSOL Multiphysics 5.1 Vibrating Membrane

2 VIBRATING MEMBRANE (1) The values k ij. are derived from the roots of the Bessel functions of the first kind. In . Table 1 the computed results are compared with the results from Equation 1 . The agreement is very good. The mode shapes for the first six modes are shown in Figure 1 through Figure 6.

Vibrating equipment for mining industry Vibroprocess

Rotational motion mechanical double deck vibroscreen 1000×3000 for limestone. The vibrating screen can separate product in three grain size with cut points of 10 mm and 40 mm. Thanks to the water addition system, composed of polyurethane nozzles placed above the screening decks, the vibroscreen can wash the limestone during the process.

Vibrating Screen, Vibratory Screener, Mining Vibrating Screen

Mineral vibrating screen is an important equipment in mineral processing plant, we should pay attention to its maintenance. Let's see why and how! 2020-02-07 05:02:34

Layout under Circular Vibrating Screen Machine and Matters

2021年12月7日Layout under Circular Vibrating Screen Machine and Matters Needing Attention in Process Design. When the vibrating screen is selected for screening equipment, the height between the center line and the floor can generally be equal to or slightly less than the width size of the screening machine. The screening machine should

Computer-aided process planning Wikipedia

Computer-aided process planning. Computer-aided process planning ( CAPP) is the use of computer technology to aid in the process planning of a part or product, in manufacturing. CAPP is the link between CAD and CAM in that it provides for the planning of the process to be used in producing a designed part. [1]

AViTEQ: Home

2023年1月31日From developing, producing and selling of drive components and controls to planning and realizing of whole vibrating and processing plants, the company is deeply rooted in German machine building, dedicating itself to a tradition of innovative engineering that sets highest quality standards. products activities references download

AViTEQ: Linear vibrating screen

AViTEQ-Vibrating screen are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker or to provide a feed to a belt conveyor or crusher.Depending on the task, the devices are designed with a robust inlet area with liners (wearing plates) followed by two or three