Dimension And Diagram Of Hippo Crusher Machine

Hippo Hammer Mills pleasanthillgrain

Hippo Hammer Mill Size Recommendations. Check out the Baby Hippo small hammer mill and Hippo #1 hammer mill for smaller machines (5-10 HP) that are extremely affordable, yet have remarkably high output, and toughness equal to their larger siblings. Look into

进一步探索

Schutte-Buffalo Hammermill Announces New OwnershipElectric Wood Hammer Mill for Sawdust Making Biopellet Small Electric Wood Hammer Mill for Home UseSmall Hammer Mill JXSC MachineSmall Hammer Mill Grain Hemp Grinder, Pleasant Hill Grain根据热度为您推荐•反馈

Hippo Hammer mills ABC Hansen Africa

Hippo Hammer Mills. A household name where hammer mills are concerned. Cast Iron. Constructed of easily replaceable special alloy cast iron wearing parts. Supplied with two

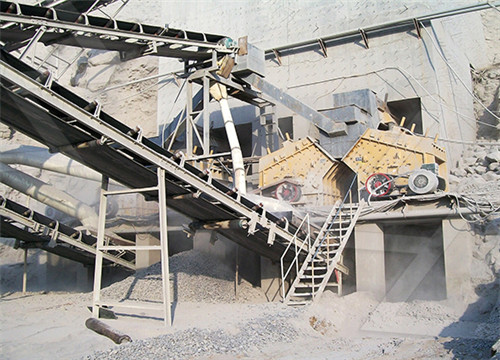

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary

(PDF) Design of Impact stone crusher machine

2019年5月31日Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at

Industrial Solutions Jaw crushers ThyssenKrupp

gle-toggle jaw crushers which can be integrated into either stationary or semi-stationary crushing plants to a model specially designed for integration into road-transportable

Jaw Crushers McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first

Dimension And Diagram Of Hippo Grinding Machine

dimension and diagram of hippo grinding machine The company mainly manufactures mobile crushers, stationary crushers, sand-making machines, grinding mills and

Dimension And Diagram Of Hippo Grinding Equipment

A Diagram Of A Grinding Machine. 2016 04 03 diagram of a grinding machine, diagram of a grinding diagram of a grinding machine products are most popular in africa, mid east,

dimension and diagram of hippo grinding machine

dimension and diagram of hippo grinding machine what is the dimension of 7af grinding machine labelled diagram of grinder Mining grinding machine diagram with

dimension and diagram of hippo grinding machine

2013 Myford Cylindrical Grinding Machine MG12 Myford Precision Cylinderical Grinders Brochure I notice the early grinder wheel head had a 1 1/2hp motor and the latter 12"

® HP400™ cone crusher Metso Outotec

Less downtime, more confidence. ® HP400™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp

Crusher an overview ScienceDirect Topics

These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The common primary crushers are of jaw and gyratory types. The jaw crusher reduces the size of large rocks by dropping them into a “V”-shaped mouth at the top of the crusher chamber.

Hippo Hammer Mills pleasanthillgrain

Hippo Hammer Mill Size Recommendations. Check out the Baby Hippo small hammer mill and Hippo #1 hammer mill for smaller machines (5-10 HP) that are extremely affordable, yet have remarkably high output, and toughness equal to their larger siblings. Look into the Hippo #1.5, Hippo #47 and Hippo #57 hammer mills for medium size (15

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Hippo Hammer mills ABC Hansen Africa

The table below shows the specifications of the various Hippo mills. All capacities based on maize through a 1.6mm screen. How Hippo Mills got its name Hubert the Famous Hippo Watch on Subscribe To Our Newsletter Join our mailing list to receive the latest news and updates from our team. SUBSCRIBE!

All Metso Corporation catalogs and technical brochures

RCS™ 300 Flotation Machine Brochure. 8 Pages. RCS™ Flotation Machines Brochure. 8 Pages. Air Classifiers Accurate Fines Control for Engineered Sands Brochure. Barmac® B Series™ Vertical Shaft Impact (VSI) Crusher Orange Series Rotor Brochure. 16 Pages. ® MP 2500 Cone Crusher Brochure. 4 Pages. ® MP 1250 Cone

Industrial Solutions Jaw crushers ThyssenKrupp

gle-toggle jaw crushers which can be integrated into either stationary or semi-stationary crushing plants to a model specially designed for integration into road-transportable plants. The single-toggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 r.p.m. possible

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

and the required dimensions of the crusher for the optimum performance have been found. These data’s were then transformed into a real time model by manufacturing it. The designed crusher was then checked and the crusher effectively crushed all the components with ease and with reduced human effort.

Dimension And Diagram Of Hippo Grinding Machine

dimension and diagram of hippo grinding machine The company mainly manufactures mobile crushers, stationary crushers, sand-making machines, grinding mills and complete plants that are widely used in mining, construction, highway, bridge, coal, chemical, metallurgy, refractory matter, etc. Product quality is

Design and Development of a Plastic Bottle Crusher IJERT

bottle crushing machine is a hand operated machine and thus it is important to have an optimum usage of effort. Accordingly, the mechanism was designed. This conceptualized machine should also have the agility to crush bottles of different dimensions and hence the dimensions and other design aspects were chosen accordingly.

(PDF) 3-D designing of an organic waste crusher ResearchGate

2019年6月11日The steps for designing the organic waste crusher involve determining a conceptual physical geometry, conducting mechanical design, and finally, developing a 3-D working drawing. Manufacturing...

Design and Construction of a Small Scale Sugarcane Juice Extractor

2019年10月16日The machine was designed to extract juice from sugarcane at small scale level suitable for small and medium scale sugarcane processors. The prototype machine was designed, fabricated and assembled

PNEUMATIC CAN CRUSHER IRJET-International Research

a can crushing machine that will reduce the volume of aluminum cans by approximate eighty percent. This machine primarily usage is to save space and for recycling. Can Crusher Calculations: Can Dimensions: 2.625in in diameter (1.3125in in radius), 4.875in in height Volume 1 uncrushed can 2V = πrh 2 V = π x 1.3125x 4.875

® HP6™ cone crusher Metso Outotec

Less downtime, more confidence. ® HP6™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed. The double accumulator combination provides better reactivity of the hydraulic system.

® HP400™ cone crusher Metso Outotec

Less downtime, more confidence. ® HP400™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp

Hippo Hammer Mills pleasanthillgrain

Check out the Baby Hippo small hammer mill and Hippo #1 hammer mill for smaller machines (5-10 HP) that are extremely affordable, yet have remarkably high output, and toughness equal to their larger siblings. Look into the Hippo #1.5,Hippo #47 and Hippo #57 hammer mills for medium size (15-40 HP) requirements.

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

(PDF) Design of Impact stone crusher machine ResearchGate

2019年5月31日Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to

All Metso Corporation catalogs and technical brochures

RCS™ 300 Flotation Machine Brochure. 8 Pages. RCS™ Flotation Machines Brochure. 8 Pages. Air Classifiers Accurate Fines Control for Engineered Sands Brochure. Barmac® B Series™ Vertical Shaft Impact (VSI) Crusher Orange Series Rotor Brochure. 16 Pages. ® MP 2500 Cone Crusher Brochure. 4 Pages. ® MP 1250 Cone

Industrial Solutions Jaw crushers ThyssenKrupp

gle-toggle jaw crushers which can be integrated into either stationary or semi-stationary crushing plants to a model specially designed for integration into road-transportable plants. The single-toggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 r.p.m. possible

Shredder Drawing, Shredder Specifications,Crusher Drawings

86 574-8730 5555. 86 574-8730 2337. prosino@sinobaler. prosino-shredder. 1206 Yinzhou Shanghui Nan Lou, 1299 Yinxian Avenue, Yinzhou District, Ningbo 315192, P.R.China

DESIGN AND FABRICATION OF THE DOUBLE ACTING CAN

stage .The design of this machine require optimum load to crush metals and will not strain the user or operator .we have designed the double acting crushing machine using modeling software's and required dimensions of the crusher for the optimum performance have been found. Designed crusher effectively crushed the components with easily and

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

and the required dimensions of the crusher for the optimum performance have been found. These data’s were then transformed into a real time model by manufacturing it. The designed crusher was then checked and the crusher effectively crushed all the components with ease and with reduced human effort.

Design and Development of a Plastic Bottle Crusher IJERT

bottle crushing machine is a hand operated machine and thus it is important to have an optimum usage of effort. Accordingly, the mechanism was designed. This conceptualized machine should also have the agility to crush bottles of different dimensions and hence the dimensions and other design aspects were chosen accordingly.

Design and Construction of a Small Scale Sugarcane Juice Extractor

2019年10月16日The machine was designed to extract juice from sugarcane at small scale level suitable for small and medium scale sugarcane processors. The prototype machine was designed, fabricated and assembled

PNEUMATIC CAN CRUSHER IRJET-International Research

a can crushing machine that will reduce the volume of aluminum cans by approximate eighty percent. This machine primarily usage is to save space and for recycling. Can Crusher Calculations: Can Dimensions: 2.625in in diameter (1.3125in in radius), 4.875in in height Volume 1 uncrushed can 2V = πrh 2 V = π x 1.3125x 4.875

® HP6™ cone crusher Metso Outotec

Less downtime, more confidence. ® HP6™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed. The double accumulator combination provides better reactivity of the hydraulic system.

Gyratory Crusher Explained saVRee

A crusher is a machine designed to reduce the size of Run of Mine (ROM) large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the ore via conveyors etc. Crushing is the first of many stages that lead to separation of the ore from the waste ( gangue) material.

- 砖料场简介

- 碎石洗选 环评

- 磨面机器

- 青海矿藏分布适合露开采的

- 碎布粉碎机

- Small Gold Ore Crushing Equipment Sand Mining In Kallada Riv

- 理石切割设备水泵

- 凹凸棒粘土生产工艺及设备开发

- Ball Mill Maintanance Checks In Yemen

- 鄂破3575破出来的料有多大

- Portable Crusher Contractor Texas

- Mineral Rubber Ball Mill With 550 950kgph

- Ore Ball Mills Sale Canada

- 山源M1214破碎机

- 乡镇砂石场安全管理实施方案