How To Maintain A Stone Crusher

Tips for Crusher Maintenance Thomasnet

2018年11月28日Stone wheels grind grain or other items into a fine powder through weight and the abrasiveness of the grinding surface.

How to maintain stone crusher equipment? linkedin

2023年2月1日To maintain the stone crusher equipment, follow these steps: Regularly inspect the equipment: Check for loose bolts, leaks in the hydraulic and lubrication

How to maintain the stone crusher linkedin

2023年2月20日Here are some tips on how to maintain a stone crusher: 1.Regularly inspect and clean the machine: Check the machine for any signs of wear or damage, and

Tips to maximize crushing efficiency PitQuarry

2019年5月13日This promotes stone-on-stone crushing, breaking up flaky or slabby particles. If you seek fewer fines, trickle feeding material into the jaw crusher could

How to Effectively Maintain Mobile Crushers goldenmeancap

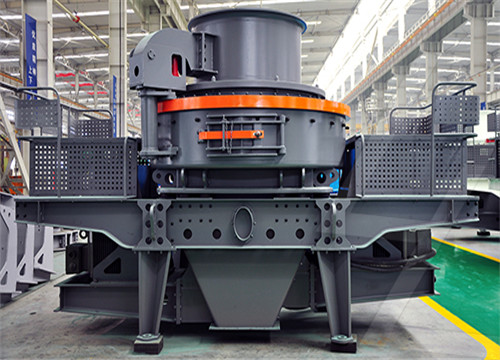

A stone crusher machine is a machine used to pulverize rocks and minerals into smaller particles. It is typically used in mineral processing plants, quarries, and other industrial

Stone Crusher Crushing BIG Stone YouTube

2013年2月7日Stone Crusher Crushing BIG StoneA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.Crushers may be used to reduce...

How Do I Maintain Crusher Fines Trails? Home Guides SF Gate

7. Refresh the trail surface by adding a 2- to 4-inch layer of fresh crusher fines on top of the old surface. Dampen it slightly by sprinkling with water, and then compact the entire trail

Amazing Quarry Primary Rock Crushing Machine

2020年6月19日Amazing Quarry Primary Rock Crushing Machine Working, Stone Processing by Crusher🔥🔥 Subscribe Fantastic Machinery: bit.ly/2rJL9StDream Catcher by Ke...

How to Maintain Jaw Crusher for Stone? stonecrushercn

(3) Overhaul of jaw crusher for stone: Except all the medium repair work, overhaul includes replacing the eccentric shaft and moving jaw mandrel, do casting on the babbitt metal on

FAQ: Tips and Techniques for using Crusher fines

Crusher fines applied over landscape fabric to a depth of 4-6 inches. Accessible crushed stone trails should be designed and constructed at grades less than 8% grade to

Tips for Crusher Maintenance Thomasnet

2018年11月28日Keep a log of maintenance checks to ensure they are completed on time. Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies

Tips to maximize crushing efficiency PitQuarry

2019年5月13日To keep your site crushing efficiently and reduce the number of fines produced, here are some tips and best practices you can follow: Feeding jaw crushers Jaw crushers are routinely choke fed, as this maximizes production capacity and ensures particles are uniformly broken.

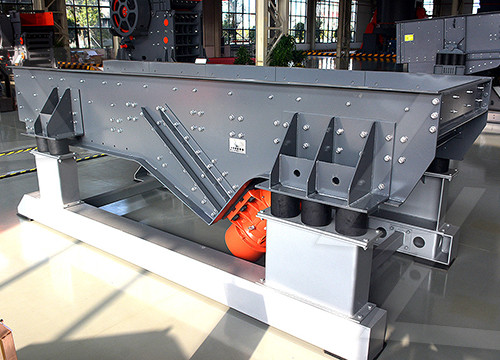

Tips for maintaining efficiency in crushing circuits

2019年4月1日Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber. Low oil temperature should prevent operation of the unit. High oil temperature

How to Effectively Maintain Mobile Crushers goldenmeancap

The maintenance of a stone crusher machine involves regular inspection and maintenance to ensure that it operates properly and efficiently. In addition, it is important to regularly clean the surface of the device to ensure that it does not become clogged with dirt, debris, or

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

DIY Home Made Rock Pulverizer Rock Crusher YouTube

2017年6月25日My Homemade / DIY Drill Mount Rock Crusher for small batch sampling.Just a regular grinder and all-thread rod mounted to a drill. Work real good.

How to Maintain Jaw Crusher for Stone? stonecrushercn

(3) Overhaul of jaw crusher for stone: Except all the medium repair work, overhaul includes replacing the eccentric shaft and moving jaw mandrel, do casting on the babbitt metal on the upper part of the connecting rod head, replacement or repair of all wear parts. In General overhaul cycle is about five years.

Stone Crusher Crushing BIG Stone YouTube

2013年2月7日Stone Crusher Crushing BIG Stone MrZygy3 3.2M subscribers Subscribe 536 277K views 9 years ago Stone Crusher Crushing BIG Stone A crusher is a machine designed to reduce

FAQ: Tips and Techniques for using Crusher fines surfacing for trails

Crusher fines applied over landscape fabric to a depth of 4-6 inches. Accessible crushed stone trails should be designed and constructed at grades less than 8% grade to promote accessible use. Overall trail grade averages of less than 6% will provide the most user-friendly experience and offer the most sustainable natural trail surface if

Cone Crushers VS Impact Crushers, Which Is Better?

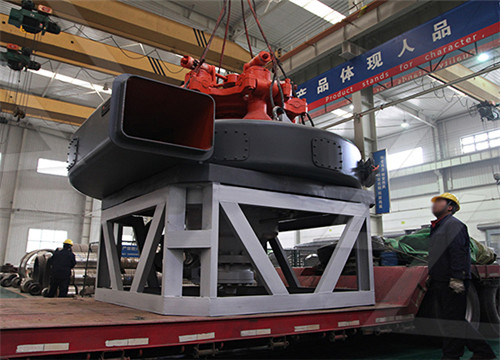

2023年3月7日The cone crusher mainly includes a single-cylinder cone crusher, multi-cylinder hydraulic cone crusher, full-liquid pressure cone crusher, etc., the high crushing cavity type, and the high broken

how to stone crusher machine works linkedin

2023年3月10日 group. Stone crusher machines are designed to crush and grind various types of rocks and minerals into smaller pieces. The process of crushing and grinding starts with the raw material

How to Stabilize a Steep Gravel Driveway TRUEGRID Pavers

The stone dust will settle and become compact to create a semisolid surface that is smooth. It is important that you know that this type of surface gravel needs to be sloped towards the sides of your driveway for better drainage. 3. Pea Gravel Pea gravel is popular gravel for driveway aesthetics.

How Much Crushed Stone Do You Need? A Sure-Fire Formula

2022年2月25日Multiply the length (L), in feet, by the width (W), in feet, by the height (H), in feet, and divide by 27. This number is how many cubic yards of crushed stone you need. As an example, let's say your DIY project is a patio, and it calls for the use of crushed stone as a base. If your patio is 20 feet long and 10 feet wide, and you need 6 inches

How to Keep Gravel in Place on Driveways and Walkways

One easy, DIY way to help prevent the spread of gravel is to tamp and pack it a bit. This simply means using a hoe or other tool to pack your gravel down tightly, and then spraying it down with water. The water will help the gravel shift around and settle into place better, loosening the soil below and allowing it to better accept the rocks.

Maintenance of Material Handling Equipment

On crushers, those other parts may include blow bars (on impact crushers), shoes and anvils, and wear plates, among others. Checking oil and filters daily, and changing those out at manufacturer-recommended

Tips to maximize crushing efficiency PitQuarry

2019年5月13日To keep your site crushing efficiently and reduce the number of fines produced, here are some tips and best practices you can follow: Feeding jaw crushers Jaw crushers are routinely choke fed, as this maximizes production capacity and ensures particles are uniformly broken.

How to Maintain Mobile Crushers For Construction

2015年8月5日A daily visual inspection of the crusher is recommended. Wear on this component depends on the application and the rock being crushed, therefore you need to keep a close eye on it. Conveyors...

Crusher Maintenance Screening Equipment

The efficiency of your crusher and screening equipment will ensure the rest of your process runs smoothly and with minimal maintenance. This equipment receives harsh wear from the material it’s processing, so

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

How to Maintain Jaw Crusher for Stone? stonecrushercn

(3) Overhaul of jaw crusher for stone: Except all the medium repair work, overhaul includes replacing the eccentric shaft and moving jaw mandrel, do casting on the babbitt metal on the upper part of the connecting rod head, replacement or repair of all wear parts. In General overhaul cycle is about five years.

DIY Home Made Rock Pulverizer Rock Crusher YouTube

2017年6月25日DIY Home Made Rock Pulverizer Rock Crusher OaksTrails Hirst 801 subscribers Subscribe 141K views 5 years ago My Homemade / DIY Drill Mount Rock Crusher for small batch

Amazing Quarry Primary Rock Crushing Machine Working, Stone YouTube

2020年6月19日Amazing Quarry Primary Rock Crushing Machine Working, Stone Processing by Crusher Fantastic Machinery 102K subscribers Subscribe 2.2K 616K views 2 years ago Amazing

5 Granite Stone Crushers: Which is Best for Granite Crushing?

2023年3月9日1, Granite is easy to obtain and rich in reserves. Granite is a kind of volcanic rock formed by the cooling condensation of magma below the surface. It is widely distributed in the world and has

Cone Crushers VS Impact Crushers, Which Is Better?

2023年3月7日The cone crusher mainly includes a single-cylinder cone crusher, multi-cylinder hydraulic cone crusher, full-liquid pressure cone crusher, etc., the high crushing cavity type, and the high broken

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher. Between these capacities, you have a choice. Source: Chris Ottergren For a hard rock mine application below 540 tonnes/hour, a jaw crusher is more economical.

FAQ: Tips and Techniques for using Crusher fines surfacing for trails

Crusher fines applied over landscape fabric to a depth of 4-6 inches. Accessible crushed stone trails should be designed and constructed at grades less than 8% grade to promote accessible use. Overall trail grade averages of less than 6% will provide the most user-friendly experience and offer the most sustainable natural trail surface if

6 Granite Crushers for Efficient Granite Crushing Fote Machinery

2023年2月28日To achieve efficient granite stone crushing, the following factors should be considered when choosing a granite crusher. 1. Wear-resistance Granite rock has high hardness and high silicon content. It is difficult to crush or requires relatively high crushing costs. The wrong choice of granite crusher will speed up the damage of wear parts, and

SAFE MAINTENANCE QUARRYING SECTOR Varnost in

A worker at a stone crushing and screening plant was seriously injured while carrying out corrective maintenance on a moving conveyor belt. The worker’s right hand was trapped in the moving belt and his right arm was dragged between the return belt and tail drum. Because the worker was wearing gloves he managed to free his arm.