Cs75d Hydraulic Concrete Crushers Maintenance

Excavator Attachments Demolition Equipment Epiroc US

But it hasn’t stopped there since then many other excavator have been added to the

进一步探索

8 Popular Excavator Attachments And Their Uses MachiShop Online Epiroc根据热度为您推荐•反馈

Concrete Crushers, Concrete Pulverizers NPKCE

Visit each concrete crusher model page below for additional images and specifications.

进一步探索

Used Concrete Pulverizer for sale. NPK equipmentmore Used Concrete Pulverizers for sale for Hunt Tractor根据热度为您推荐•反馈

Hydraulic Concrete Crusher YouTube

2013年6月4日This video shows you how to use the hydraulic concrete crusher to

Concrete Crusher Hydraulic Crusher International

The rotational crusher includes an integrated hydraulic installation that permits the multi

Pulverizer Attachments Concrete and Rock Crusher

Hydraulic bulk pulverizer BP 3050 R for excavators of 30-40 tons (66,100-88,200 lb),

Use of Hydraulic Concrete Crusher in Demolition Works

2022年8月8日Use of Hydraulic Concrete Crusher (HCC) in Demolition Works Noise

New Concrete crushers for sale Machinery Partner

We offer a range of compact crusher buckets and standalone units to match your

4 Types of Stone Crushers' Maintenance and Efficient

2023年2月15日The regular maintenance and repair include adjustment of the gap

Hydraulic Concrete CrusherPulveriser 10-16 Tonne

Hydraulic Concrete CrusherPulveriser 10-16 Tonne JB Equipment Ltd Call the JB

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a machine

Concrete Crushers, Concrete Pulverizers NPKCE

Visit each concrete crusher model page below for additional images and specifications. If you require a booster service manual or would like a hard copy of the operation and maintenance manual, please contact the Sales department at 440-232-7900 or by email at sales@npkce.

Hydraulic Concrete Crusher YouTube

2013年6月4日This video shows you how to use the hydraulic concrete crusher to break concrete walls and facade. It is a "silent demolition" tool. This equipment is availa...

Concrete Crusher Hydraulic Crusher International Attachments

The rotational crusher includes an integrated hydraulic installation that permits the multi-system to make a 360° rotation in both directions for fast, accurate and efficient positioning of the jaws in any working condition. This makes it ideal for operators who use excavators with very long booms. The concrete crusher is made of reinforced

Jaw Crushers MEKA CrushingScreening Plants

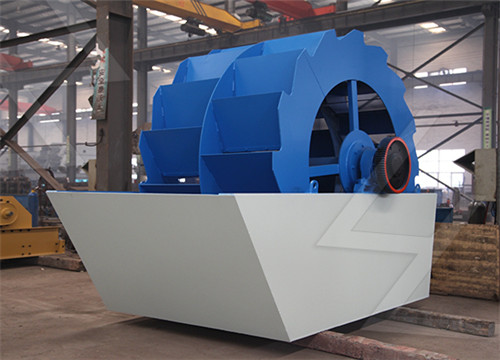

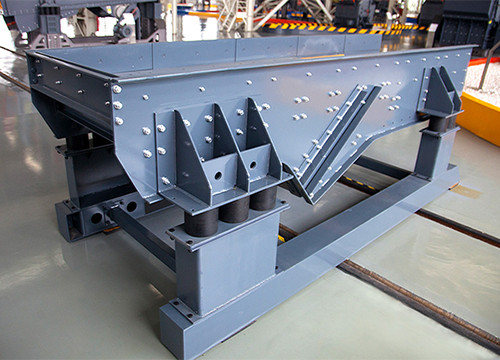

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds

concrete processor Avada Construction

Using a Sjheavy hydraulic concrete crusher in demolition or construction operations is highly recommended. Sjheavy concrete processor is the ideal demolition partner since it is powerful, adaptable, and easy to use. They were designed to be a multi-purpose crusher capable of performing primary and secondary demolition operations.

Jaw Crushers Parker Plant

Rocksizer Jaw Crushers. RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range. Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well

Concrete Pulverizer Concrete Crusher Attachment Kenco

THIS CONCRETE CRUSHING MACHINE IS A TOOL DESIGNED FOR CONTROLLED DEMOLITION AND RECYCLING OF CONCRETE SLABS, WALLS, BRIDGE DECKS, AND MORE! The Kenco concrete pulverizer jaw requires no hydraulics for it to operate.

Crushing and Screening Safety is our #1 Priority

2017年9月20日Hydraulically adjustable conveyors are safer as workers don’t have to manually lift conveyors. Tag Lines a pull cable goes the full length of the conveyor, so if pulled, the tag line kills the power and stops the crushing spread if a worker detects a dangerous situation. 4. The Hydraulic GrizzlyJaw Safety

4 Types of Stone Crushers' Maintenance and Efficient

2023年2月15日The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the hammer, lining plate, bearing temperature, etc. Replace badly wearing parts in time. Regularly inspect temperature of the rotor, motor and

Hydraulic Breakers for Excavators Jack Hammers Epiroc US

Hydraulic breakers are the oldest hydraulic attachments for carriers. The first serial manufactured rock breaker was the Krupp HM 400 in 1967 and the patent was secured in 1963. Excavator jack hammers are impact devices designed to break any kind of rock or concrete with any hardness or physical property. They have a wide range of applications

Xypex Patch’n Plug: Hydraulic Concrete Patch Compound

Patch’n Plug. Xypex Patch’n Plug is a specially designed, fast-setting hydraulic cement compound for concrete patching and repair. It stops flowing water in seconds and is used to seal cracks, tie holes, and other defects in concrete. The high performance characteristics of Patch’n Plug are enhanced by Xypex’s unique Crystalline

Hydraram HCC 95V Concrete Crusher in action! YouTube

The Hydraram concrete crushers are designed for the demolition of heavy concrete structures, where the main element is concrete with steel reinforcement.The

Pile Breaker Concrete Pile Crusher International Attachments

Hydraulic Pile Breakers. The hydraulic pile breaker is an advanced, efficient and time-saving system for trimming concrete outcrops and foundation piles. The pile breaker produces a perfect horizontal pile cutting finish, it doesn’t damage the reinforcement or leave cracks below the cut-off level. This efficient pile cutting system is.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure.

Concrete Crushers, Concrete Pulverizers NPKCE

Visit each concrete crusher model page below for additional images and specifications. If you require a booster service manual or would like a hard copy of the operation and maintenance manual, please contact the Sales department at 440-232-7900 or by email at sales@npkce.

Concrete Crusher Hydraulic Crusher International Attachments

The concrete crusher is made of reinforced HARDOX and WELDOX steel and features a two-cylinder system for improved durability and reliability. The clutching installation permits a constant 360° rotation making it perfect for excavators without a rotation installation. New PRV System Auto Frictioning Rotation Valve Reversed Cylinder

Jaw Crushers MEKA CrushingScreening Plants

“Crusher performance may vary depending on the feed gradation, feed moisture content, crushability of the material, crusher rpm, installed power and the crushing circuit design. Please consult MEKA for specific applications” Jaw Crusher PDF, 9.3 MB LEADER IN PRIMARY JAW CRUSHERS

Jaw Crushers Parker Plant

Rocksizer Jaw Crushers. RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range. Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well

Pile Breaker Concrete Pile Crusher International Attachments

Hydraulic Pile Breakers. The hydraulic pile breaker is an advanced, efficient and time-saving system for trimming concrete outcrops and foundation piles. The pile breaker produces a perfect horizontal pile cutting finish, it doesn’t damage the reinforcement or leave cracks below the cut-off level. This efficient pile cutting system is.

Hydraulic Breakers for Excavators Jack Hammers Epiroc US

Hydraulic breakers are the oldest hydraulic attachments for carriers. The first serial manufactured rock breaker was the Krupp HM 400 in 1967 and the patent was secured in 1963. Excavator jack hammers are impact devices designed to break any kind of rock or concrete with any hardness or physical property. They have a wide range of applications

Hydraram HCC 95V Concrete Crusher in action! YouTube

The Hydraram concrete crushers are designed for the demolition of heavy concrete structures, where the main element is concrete with steel reinforcement.The

concrete processor Avada Construction

Using a Sjheavy hydraulic concrete crusher in demolition or construction operations is highly recommended. Sjheavy concrete processor is the ideal demolition partner since it is powerful, adaptable, and easy to use. They were designed to be a multi-purpose crusher capable of performing primary and secondary demolition operations.

Xypex Patch’n Plug: Hydraulic Concrete Patch Compound

Patch’n Plug. Xypex Patch’n Plug is a specially designed, fast-setting hydraulic cement compound for concrete patching and repair. It stops flowing water in seconds and is used to seal cracks, tie holes, and other defects in concrete. The high performance characteristics of Patch’n Plug are enhanced by Xypex’s unique Crystalline

Stone Crushers for Skid Steers FAE FAE Group

Stone crushers with fixed-tooth rotor for skid steers for crushing stones and rocks up to 6" deep. the STC/SSL shreds processed material into the size you want and a hydraulic hood allows you to adjust the dosage. building and maintaining hiking trails, bike paths and horse trails, dirt and gravel road maintenance. Watch the video of

Tehma CC300 Hydraulic Concrete Crusher Specialised Force

It can break concrete with ease and incredible power, without producing noise, vibration or dust. Structures such as reinforced concrete or brick walls, floors, pillars, stairways and other concrete or composite constructions up to 25 cm thickness can be crushed with ease.

MSD Saber-Lube Series Shears For Construction Pros

2007年6月19日Concrete CrushersShears Epiroc Adds Two Models to Combi Cutter Line Epiroc's CC 2300 and CC 3100 are designed for carriers in the 20- to 30-ton and 25- to 40-ton operating weight classes