Crushing For Raw Material Quartz

Quartz Manufacturing Process Step by Step Bsg Glass

2021年11月16日The crushing process of quartz is done with a crusher while a vibrating screen is used to separate it. Next a ball milling is used to ground the quartz. Lastly, the

Jaw Crushers high quality and reliability from RETSCH

The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The

进一步探索

Laboratory Jaw Crusher 911MetallurgistWhat is a Jaw Crusher? MEKA Crushing Equipment根据热度为您推荐•反馈

Factory-Made Quartz Countertops Need To Be Cut Safely

2019年12月2日The mixture gets spread out onto what looks like a giant baking sheet, then goes through a machine that vibrates the material in a vacuum to remove any voids.

Extracting gold from rock OpenLearn Open University

The Challenge. Unlike alluvial gold, which is found as very small flakes on river banks, gold

3 Ways to Identify Gold in Quartz wikiHow

2023年2月9日Crush your quartz until it is a fine powder. Place your piece of quartz in the mortar, or bowl of your mortar and pestle set. Press hard on it with the pestle until pieces

Over 60 Aggregates for Quartz CountertopTile

Kafka Granite has nearly 60 colors of natural stone and recycled materials for use in manufactured quartz countertops and tiles. These beautifully colored crushed stone chips add natural color and unique character to

Table of Bond Work Index by Minerals Mineral Processing

2015年6月19日Source 1: Table of materials reported by Fred Bond Source 2: Outokumpu, The science of comminution Source 3: Equipment and pipelines Source 4:

Silica Sand Manufacturing Process Silica Sand Extraction

Then, the grinding product enters the grading operation, and the quartz sand which meets the particle size requirement can be used as the raw material quartz sand for the next stepping of removing and purifying

Aggregate Crusher Turn Stone Materials Into Building

PE750 1060 jaw crusher Model: PE-750*1060 Feed opening size (mm): 750*1060 Max.Feeding size (mm): 630 Adjusting range of discharge opening (mm): 80-140 Processing capacity (t/h): 110-320 Rotation speed

Innovative Processing Techniques for the Production of a Critical Raw

2013年1月1日Depending on the final quality and value,processing of the raw quartz into high purity quartz involves advanced beneficiation techniques including comminution technology, physical, thermal and chemical steps.

Assessing raw material’s role in bipolar and freehand

2018年5月8日The milky quartz bipolar flakes show significant differences in their higher ventral surface crushing and shearing technological strategy (bipolar or freehand), raw material (quartz or flint), and their interaction as the independent variables. Full size table. Fig. 8. Flake shape comparisons by raw material and technology. Full size image

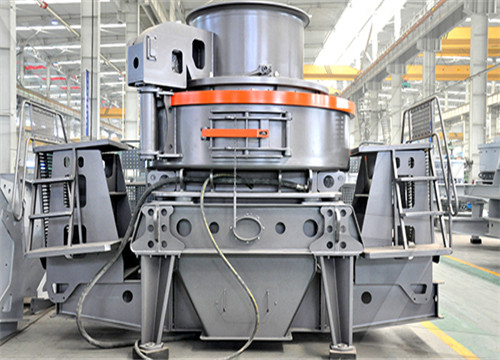

Cone crusher basics in 4 minutes SRP

It is vital that you know, as accurately as you can, the size distribution of the raw material. The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher. Sampling is a vital part of

Mineralogy and Processing of Hydrothermal Vein Quartz from

2017年7月19日Quartz occurs in many geological materials, and is used in numerous industrial fields as a raw material. Mineralogy and the processing of hydrothermal quartz were studied by optical microscope, electron probe microanalysis, scanning electron microscope, inductively coupled plasma-optical emission spectrometry, and inductively

CNU Raw material crushing device for quartz rod

The utility model discloses a raw materials breaker is used in quartz rod production, including breaker shell, first squeeze roll, stripper plate, second squeeze roll and third squeeze roll, the top of breaker shell is provided with the dog-house, the one end at top is provided with first squeeze roll in the breaker shell, the one end of first squeeze roll is

An evaluation of the procedure and results of laboratory

crushing plant, are products. EN testing standards are ap-plied to products, not raw materials. However, the quality of the rock ‘‘raw material’’ from which the aggregate is pro-duced is often established on aggregates that have been crushed with a laboratory crusher rather than a multi-stage crushing plant. Testing is performed

Silica Sand Manufacturing Process Silica Sand

Then, the grinding product enters the grading operation, and the quartz sand which meets the particle size requirement can be used as the raw material quartz sand for the next stepping of removing and purifying

Mechanochemistry in crushing of ceramic raw materials

2020年11月20日PDF On Nov 20, 2020, László A Gömze published Mechanochemistry in crushing of ceramic raw materials Find, read and cite all the research you need on ResearchGate

Aggregate Crusher Turn Stone Materials Into

PE750 1060 jaw crusher Model: PE-750*1060 Feed opening size (mm): 750*1060 Max.Feeding size (mm): 630 Adjusting range of discharge opening (mm): 80-140 Processing capacity (t/h): 110-320 Rotation speed

Quartz sand raw ore is separated by PTMS magnetic separator

Although quartz mineral resources are rich, but the quality is not good, the content of hybrid, more lean ore, less rich ore, high-grade quartz ore is rare, only by using certain means to separate and purify quartz sand ore can be used as industrial raw materials. Contact: DELLA Mob: +86- sales@powtechina

Applied Sciences Free Full-Text Rock Material Recycling in

2020年3月17日Via this selection process, small and concurrently inferior components—from a petrographical point of view—are excluded and thereby the overall quality of the to be processed raw material is improved. Thereupon, the preconditioned rock material experiences a pre-crushing and a second screening (ca. 32 mm of screen

Factory-Made Quartz Countertops Need To Be Cut Safely To Control NPR

2019年12月2日Cambria produces around 30,000 slabs of quartz countertop material every month, says Davis, who adds that the company has also spent millions of dollars on air-handling systems to control dust

Table of Bond Work Index by Minerals Mineral Processing

2015年6月19日Source 1: Table of materials reported by Fred Bond Source 2: Outokumpu, The science of comminution Source 3: Equipment and pipelines Source 4: Tenova Bateman mills (AG/SAG, Rod, Ball Mill) Source 5: Doering international GmbH cylpebs Source 6: SME handbook of mineral processing, N.L Weiss Editor, NY

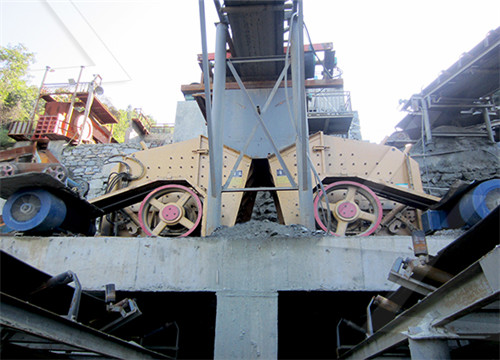

how to stone crusher machine works

2023年3月10日 group. Stone crusher machines are designed to crush and grind various types of rocks and minerals into smaller pieces. The process of crushing and grinding starts with the raw material

Assessing raw material’s role in bipolar and freehand

2018年5月8日The milky quartz bipolar flakes show significant differences in their higher ventral surface crushing and shearing technological strategy (bipolar or freehand), raw material (quartz or flint), and their interaction as the independent variables. Full size table. Fig. 8. Flake shape comparisons by raw material and technology. Full size image

Cone crusher basics in 4 minutes SRP

It is vital that you know, as accurately as you can, the size distribution of the raw material. The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher. Sampling is a vital part of

CNU Raw material crushing device for quartz rod

The utility model discloses a raw materials breaker is used in quartz rod production, including breaker shell, first squeeze roll, stripper plate, second squeeze roll and third squeeze roll, the top of breaker shell is provided with the dog-house, the one end at top is provided with first squeeze roll in the breaker shell, the one end of first squeeze roll is

An evaluation of the procedure and results of laboratory

crushing plant, are products. EN testing standards are ap-plied to products, not raw materials. However, the quality of the rock ‘‘raw material’’ from which the aggregate is pro-duced is often established on aggregates that have been crushed with a laboratory crusher rather than a multi-stage crushing plant. Testing is performed

Mechanochemistry in crushing of ceramic raw materials

2020年11月20日PDF On Nov 20, 2020, László A Gömze published Mechanochemistry in crushing of ceramic raw materials Find, read and cite all the research you need on ResearchGate

Over 60 Aggregates for Quartz CountertopTile

Kafka Granite is the expert in manufacturing crushed granite, quartz, marble and recycled materials (porcelain, smoked glass, two-sided mirror, etc.) for manufactured quartz countertops and tiles. We are able to

Silica Sand Manufacturing Process Silica Sand

Then, the grinding product enters the grading operation, and the quartz sand which meets the particle size requirement can be used as the raw material quartz sand for the next stepping of removing and purifying

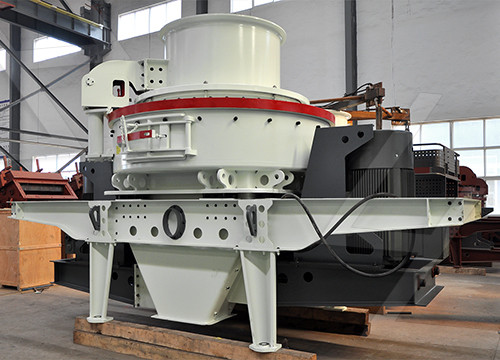

Artificial Sand What Is It and How to Make It Fote

2023年2月15日Quartz is a hard, wear-resistant, chemically stable silicate mineral mainly composed of silicon dioxide. It is an important industrial mineral raw material generally used in glass, building materials,

Aggregate Crusher Turn Stone Materials Into

PE750 1060 jaw crusher Model: PE-750*1060 Feed opening size (mm): 750*1060 Max.Feeding size (mm): 630 Adjusting range of discharge opening (mm): 80-140 Processing capacity (t/h): 110-320 Rotation speed

Quartz sand raw ore is separated by PTMS magnetic separator

Although quartz mineral resources are rich, but the quality is not good, the content of hybrid, more lean ore, less rich ore, high-grade quartz ore is rare, only by using certain means to separate and purify quartz sand ore can be used as industrial raw materials. Contact: DELLA Mob: +86- sales@powtechina

Minerals Free Full-Text Assessment of Gold-Bearing Quartz Vein

2023年2月13日Pretreatment stage: the cleaned and dried raw quartz was manually crushed to 20–50 mm, and then it was calcined at 900 °C for 1 h before water quenching. Finally, the water-quenched ore samples were broken into the required particle size with a crusher, and 60–80 µm quartz sand was screened out for use.

Mineralogy and Processing of Hydrothermal Vein Quartz from

2017年7月19日Quartz occurs in many geological materials, and is used in numerous industrial fields as a raw material. Mineralogy and the processing of hydrothermal quartz were studied by optical microscope, electron probe microanalysis, scanning electron microscope, inductively coupled plasma-optical emission spectrometry, and inductively

Gemstone Hardness and Wearability International Gem Society

The hardness of a material may vary slightly with composition and also with its state of aggregation. Measuring gemstone hardness can be tricky. Often, a mark that looks like a scratch is actually a trail of powder left by the supposedly harder material! Remember, quartz (hardness 7) is a component of dust and one of the most common