Classifying Equipment Maintenance

1.4 Maintenance, including major maintenance PwC

2022年12月31日Many agreements to obtain access to machinery or other equipment are accounted for as leases and implicitly include operations and maintenance services. Maintenance services are an executory cost of the lease or are considered “other

进一步探索

Accounting for Repair and Maintenance Journal Entry Major overhaul IAS 16Major overhauling IFRS CPDbox1.1 Capitalization of costs chapter overview PwCAICPA根据热度为您推荐•反馈

Types of Maintenance (Definitions, Benefits, Cost, Examples)

2020年8月19日Emergency maintenance is similar to reactive maintenance—both processes require a last-minute response to the abrupt breakdown of equipment. However, emergency maintenance entails

9 Types of maintenance: How to choose the right

2021年10月22日There are 9 types of maintenance split between Preventive Maintenance and Corrective Maintenance. Preventive

(PDF) Classification of Machine Equipment ResearchGate

2011年1月1日Maintenance activities can be broadly categorized as either preventive maintenance (PM) or reactive maintenance (RM), both of

The 5 levels of maintenance Mobility Work

The 1st level maintenance corresponds to the simple interventions, necessary and realized

Classification of Maintenance Plan SAP Blogs

2019年7月7日Classification of Maintenance Plan. 4 15 5,199. Maintenance planner creates maintenance plans to ensure proper level of preventive care for various assets and avoid costly breakdowns. It is

Classifying Equipment (SAP Library Plant Maintenance

Classifying Equipment (SAP Library Plant Maintenance (PM)) Classifying Equipment Prerequisites A master record must exist for the piece of equipment The required

Classification of Assets by Criticality Enhancing Your

2018年12月1日Classification of Assets by Criticality. Classifying the Equipment by how critical they are to the process, allows the maintenance planners to better plan

Project Definition and Work Classification United

Work classification equipment classification • 2 8, page : 18: Work classification funded and unfunded project costs • 2 9, page : 27. Contents—Continued: ii : DA PAM

How to Implement Machine Learning For Predictive

2019年11月7日Predictive maintenance makes use of multi-class classification since there are multiple possible causes for the failure of a machine or component. These are possible outcomes that are classified

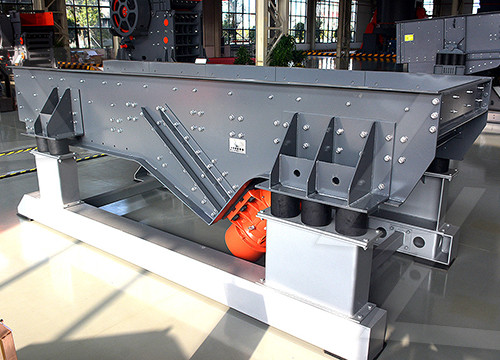

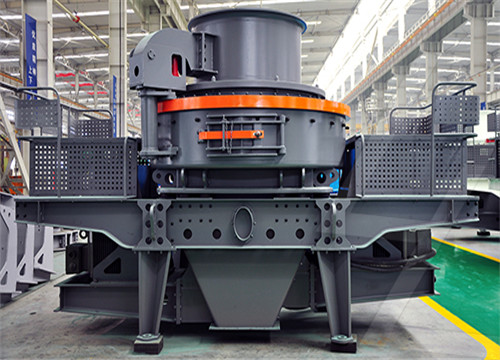

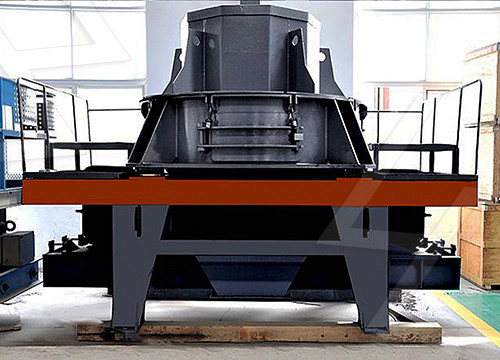

The Complete Guide to WashingClassifying McLanahan

These deposits often contain deleterious material such as clay, silt, twigs and other debris that can decrease the quality, efficiency and durability of the final products if not removed. Crushed sands often contain an excess of harmful

Optimize Equipment Hierarchy and Classification in CMMS

Once you have optimized your equipment hierarchy and classification in your CMMS, you can use them to improve your maintenance management in various ways. For example, you can create and assign

Types of Maintenance: 5 Methods Worth Training For Interplay

2020年1月14日The 5 Types of Maintenance 1. Preventive Maintenance Preventive maintenance is aimed at catching and fixing problems before they happen. It is most commonly carried out in the form of regular inspections, usually occurring multiple times

Critical Equipment Identification and Maintenance

2016年8月2日Chiefly, the common critical asset identification process should include the following aspects: A quantifiable inventory of assets. Support documentation including location, manufacturer, model number,

Data-driven Approach to Equipment Taxonomy

An equipment taxonomy is a systematic classification of equipment into a hierarchical grouping where levels are based on the complexity of equipment characterization (ISO, 2004). For example, “rotating equipment” is high-level a characterization which includes pumps, turbines and compressors but has similarities that differentiate this

Classification of Maintenance Plan SAP Blogs

2019年7月7日Newly created class can be assigned to the maintenance plans to classify it with required information as shown below. Such assignment can be done with transactions to create or change

Classification of Assets by Criticality Enhancing Your Business

2018年12月1日Equipment classified as highly profitable or with high customer service needs or high volume demands. Equipment with high repair cost when they fail. Criticality B Some reduced capacity, equipment that can be bypassed economically for a period. Components on a single line. Criticality C Comfort items (HVAC, air make-up units, etc.)

Project Definition and Work Classification United States

Work classification equipment classification • 2 8, page : 18: Work classification funded and unfunded project costs • 2 9, page : 27. Contents—Continued: ii : DA PAM 420–11 • 18 March 2010: grade, maintenance, repair, construction, revitalization, improvement, and demolition. These words have a variety of mean-

How to Maintain Construction Equipment? [PDF]

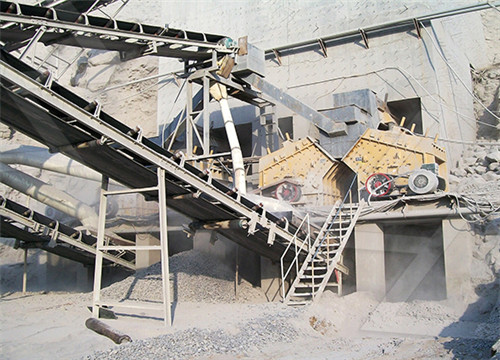

🕑 Reading time: 1 minute Proper maintenance of construction equipment decides the actual life of machinery. Maintenance of heavy machinery used in construction, industrial, or mining application is necessary to keep it in

What Is Criticality Analysis? Reliable Plant

Put together a team of personnel from the operations, maintenance, engineering and procurement side of the organization to conduct a survey of the plant equipment. Equipment operators should be included in this

Federal Wage System Job Grading Standard for

Maintenance Mechanic, 4749 TS-30 May 1974 MAINTENANCE MECHANIC, GRADE 9 General: The grade 9 maintenance mechanic performs a variety of tasks involved in the upkeep of buildings, grounds and related structures, fixtures, and utilities. Typical work assignments include the visual examinations and operational tests to determine the need

JMSE Free Full-Text Research on Multi-Fault Identification of

The marine vertical centrifugal pump is an important piece of auxiliary equipment for ships. Due to the complex operating conditions of marine equipment and the frequent swaying of the hull, typical pump failures such as rotor misalignment, rotor unbalance and mechanical loosening occur frequently, which seriously affect the service life of the marine vertical

COMMON MAINTENANCE TOOLS AND THEIR USES

your equipment and replace it. Perform maintenance periodically according to applicable procedures. Remember that leather and nylon belts are treated in different manners. 1-3

How to Implement Machine Learning For Predictive

2019年11月7日Predictive maintenance makes use of multi-class classification since there are multiple possible causes for the failure of a machine or component. These are possible outcomes that are classified

The Complete Guide to WashingClassifying McLanahan

These deposits often contain deleterious material such as clay, silt, twigs and other debris that can decrease the quality, efficiency and durability of the final products if not removed. Crushed sands often contain an excess of harmful

Optimize Equipment Hierarchy and Classification in CMMS

Once you have optimized your equipment hierarchy and classification in your CMMS, you can use them to improve your maintenance management in various ways. For example, you can create and assign

Critical Equipment Identification and Maintenance

2016年8月2日Chiefly, the common critical asset identification process should include the following aspects: A quantifiable inventory of assets. Support documentation including location, manufacturer, model number,

Classification of Maintenance Plan SAP Blogs

2019年7月7日Newly created class can be assigned to the maintenance plans to classify it with required information as shown below. Such assignment can be done with transactions to create or change

Classifying Equipment for maintenance There are four

Classifying Equipment for maintenance There are four components of RCM program which are, 1. Reactive Maintenance 2. Preventive Maintenance 3. Predictive Maintenance 4. Proactive...

Project Definition and Work Classification United States

Work classification equipment classification • 2 8, page : 18: Work classification funded and unfunded project costs • 2 9, page : 27. Contents—Continued: ii : DA PAM 420–11 • 18 March 2010: grade, maintenance, repair, construction, revitalization, improvement, and demolition. These words have a variety of mean-

Chapter 5. Autonomous Maintenance. Part 1

2020年11月30日The 7 steps for developing Autonomous Maintenance can be grouped into the three stages described below: Stage 1. Steps 1 to 3 constitute Stage 1. This is where the basic equipment conditions are

COMMON MAINTENANCE TOOLS AND THEIR USES

your equipment and replace it. Perform maintenance periodically according to applicable procedures. Remember that leather and nylon belts are treated in different manners. 1-3

How to Maintain Construction Equipment? [PDF]

🕑 Reading time: 1 minute Proper maintenance of construction equipment decides the actual life of machinery. Maintenance of heavy machinery used in construction, industrial, or mining application is necessary to keep it in

A Smart Predictive Maintenance Scheme for Classifying Diagnostic

2021年10月26日On the use of lstm networks for predictive maintenance in smart industries. In: 2019 IEEE International Conference on Smart Computing (SMARTCOMP). IEEE (2019) Google Scholar Wu, H., Huang, A., Sutherland, J.W.: Avoiding environmental consequences of equipment failure via a LSTM-based model for predictive maintenance.

Fine Material Screw Washers McLanahan

The design of a McLanahan Fine Material Screw Washer provides significant advantages over other sand screws you could consider that include: Larger pool settling areas behind the feed box/baffle plate that provide higher retention of +75 micron (200 mesh) product sized solids. A machine design that has a 2.5" (65mm) gap between the screw shaft

CapEx vs OpEx: Capital ExpendituresOperating Expenses

2021年4月1日When it comes to procuring new equipment, capabilities, and software, IT professionals generally have two options: Obtaining new capabilities and equipment as a capital expenditure (CapEx). Obtaining them as an operating expense (OpEx).