2013 Mining Copper Ore Grinding Mill

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017年3月4日Ball mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas

Grinding Mills Mineral Processing Equipment CITIC HIC

Western Mining Group's Yulong Copper Mine Project in Tibet (Altitude 4660m 60,000t/d) 4 SAG mills, Ø8.8×4.8m 4 overflow discharge ball mills, Ø6.2×10.5m Kamoa-Kukula Copper Mine Phase IPhase II in DR

Inside a mining company’s AI transformation McKinsey

2020年2月5日The mood was apprehensive as data scientists, metallurgists, and engineers from Freeport-McMoRan filed into the

Copper Flotation Mineral ProcessingMetallurgy

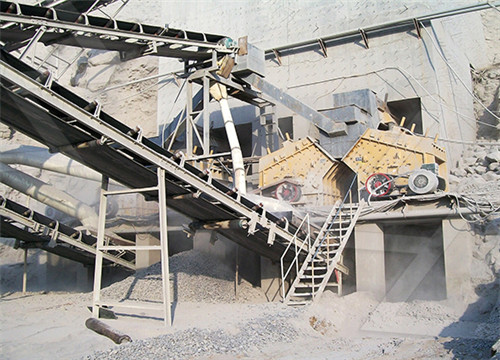

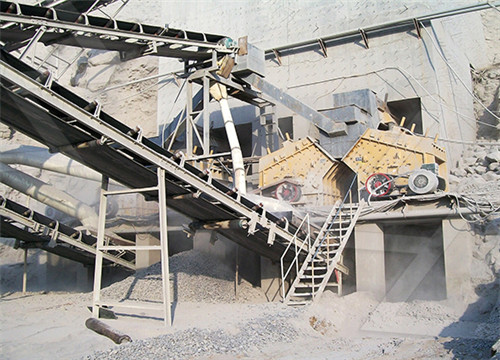

2016年5月16日During prolonged periods of crusher maintenance the ore walls can be bulldozed over the ore feeders to provide an uninterrupted supply of ore for milling. GRINDING COPPER ORE. As it is shown in

Copper Mining and Processing: Processing Copper Ores

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday

Copper Ore Crushing, GrindingFlotation

2017年5月21日Grinding and Flotation. Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the open-circuit 2600mm x 3960mm (8’-6 x 13’-0) Hardinge rod mill at an average feed rate of 2,106 STPD or

Mineral Processing Equipment Ore Grinding Machine CITIC HIC

CITIC HIC is an experienced company specialized in designing and manufacturing mineral processing equipment, including grinding mills, crushers, vertical stirred mills, mine

Rod Mills Grinding Mills DOVE

DOVE Rod Mills are highly efficient grinding mills commonly used in minerals processing and particle size reduction through friction, attrition and compressive forces, designed to

Factors Influence Ore Grinding Mill Efficiency JXSC Mining

2019年5月10日By the way, the larger the diameter of the ball mill, the lower the filling rate. For the rod mill, the filling rate is generally 10% lower than that of the ball mill of the

A comparative study on the effects of dry and wet grinding on

2019年9月1日Grade and recovery of PGM in different HPGR-rod mill grinding environments . (2013) showed that dry grinding of a PGM ore by using mild steel media could liberate a higher percentage of PGM particles than wet grinding by mild steel and Copper ore grinding in a mobile vertical roller mill pilot plant. Int J Miner Process, 136

A STUDY OF FLOTATION KINETICS OF THE HYDROCYCLONE

underflow is returned to the grinding process in the ball mill. Grinding and classification of high-grade copper ore is shown in Figure 1. Capacity of industrial processing of high-grade copper ore in the Copper Mine Bor is 80 t/h. Designed fineness of the final grinding product is 60 % with class participation -0.074 mm.

(PDF) INVESTIGATION ON FLOTATION BEHAVIOR

2019年8月1日Such an improved performance in cement grinding operations encouraged the research studies on ore grinding applications. of Mining and Metallurgy, 2013. Mill in a sulphide Copper-Gold ore

Microwave Pretreatment on Copper Sulfide Ore: Comparison of Ball Mill

2021年7月8日A copper sulfide ore was crushed to 100% passing 3.36 mm, then the crushed product was ground by bed breakage or ball milling. The effect of microwave pretreatment on ball mill grinding and bed breakage was investigated in terms of mineral liberation, particle shape, and floatability.

sbm/sbm 2013 mining grinding mill for copper ore.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Minerals Free Full-Text Evaluation of the Relationship between

The study evaluated the milling kinetics of three copper ores, from a multi-mineralised deposit, which were identified as sulphide 1 (with bornite as a dominant copper mineral), sulphide 2 (mainly composed of chalcopyrite) and oxide (with malachite as a dominant copper mineral) and related the breakage parameters to the mineral composition data.

(PDF) Effects of High Pressure ORE Grinding on the

2014年1月20日High pressure grinding rolls in AG/SAG mill circuits -the next step in the evolution of grinding plants for the new millennium. SAG 2001, Conference, Vancouver, B.C. 2001. Vol.

Factors Influence Ore Grinding Mill Efficiency JXSC Mining

2019年5月10日Take a gold mine as an example, reducing ore particle from -15mm to -10mm improve the grinding efficiency from 1150 tons per day to 1500 tons per day, and decrease the steel consumption and electric power consumption by 1.53kg/t to 1.1kg/t and 41.57kWh to 29.2kWh respectively. 2 Milling medium

左蔚然- 福州大学紫金地质与矿业学院 Zijin School of Geology and Mining

2009.09-2013.07 中国矿业大学化工学院 博士研究生 矿物加工工程 . 2005.09-2008.07 中国矿业大学化工学院 硕士研究生 矿物加工工程

Ore Grade Control Procedures

ore grade control in mining ? Grinding Mill China June 17th, 2018 Grade Control Classification of Ore and Waste A Critical Review of Estimation and Simulation Based Procedures ? Learn More ore grade control in December 31st, 2013 Understanding blast movement to optimise grade control designs to promote controlled blast movement

Rod Mills Grinding Mills DOVE

DOVE Rod Mills are highly efficient grinding mills commonly used in minerals processing and particle size reduction through friction, attrition and compressive forces, designed to grind and blend various bulk material ranging from soft, fibrous to hard and brittle material. Mainly used in size reduction of Coal/ Coke, Feldspar, Quartz minerals, Tungsten Tin

Buy Ore Ball Mill for Mineral Processing IronGold Ore Ball Mill

Ore Ball Mill. Output size: 0.074-0.89mm. Motor power: 18.5-480kw. Specification (mm): Φ750×750-Φ2700×4500. Applications: It is used for processing various grindable mineral materials, non-ferrous metal mineral processing, new building materials, etc. Email: info@ballmillssupplier. Now.

Gold, Silver, Copper, Oil, Gas, Mining # 💥💥[HOT SALE] 1- 20 tph

# [HOT SALE] 1- 20 tph Copper Ore Grinding ball mill # click our official website for【pricedetails】: #...

Floor Mounted Laboratory Grinding Mill 911Metallurgist

This Grinding Mill is fully enclosed with sound dampening material for a quiet workplace. The sheet metal steel fabrication provides full enclosure around the main frame and door. The yoke (grinding cylinder) is totally balance and

A comparative study on the effects of dry and wet grinding on

2019年9月1日Grade and recovery of PGM in different HPGR-rod mill grinding environments . (2013) showed that dry grinding of a PGM ore by using mild steel media could liberate a higher percentage of PGM particles than wet grinding by mild steel and Copper ore grinding in a mobile vertical roller mill pilot plant. Int J Miner Process, 136

A STUDY OF FLOTATION KINETICS OF THE HYDROCYCLONE

underflow is returned to the grinding process in the ball mill. Grinding and classification of high-grade copper ore is shown in Figure 1. Capacity of industrial processing of high-grade copper ore in the Copper Mine Bor is 80 t/h. Designed fineness of the final grinding product is 60 % with class participation -0.074 mm.

(PDF) INVESTIGATION ON FLOTATION BEHAVIOR

2019年8月1日Such an improved performance in cement grinding operations encouraged the research studies on ore grinding applications. of Mining and Metallurgy, 2013. Mill in a sulphide Copper-Gold ore

sbm/sbm 2013 mining grinding mill for copper ore.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Minerals Free Full-Text Evaluation of the Relationship between

The study evaluated the milling kinetics of three copper ores, from a multi-mineralised deposit, which were identified as sulphide 1 (with bornite as a dominant copper mineral), sulphide 2 (mainly composed of chalcopyrite) and oxide (with malachite as a dominant copper mineral) and related the breakage parameters to the mineral composition data.

(PDF) Effects of High Pressure ORE Grinding on the

2014年1月20日High pressure grinding rolls in AG/SAG mill circuits -the next step in the evolution of grinding plants for the new millennium. SAG 2001, Conference, Vancouver, B.C. 2001. Vol.

Rod Mills Grinding Mills DOVE

DOVE Rod Mills are highly efficient grinding mills commonly used in minerals processing and particle size reduction through friction, attrition and compressive forces, designed to grind and blend various bulk material ranging from soft, fibrous to hard and brittle material. Mainly used in size reduction of Coal/ Coke, Feldspar, Quartz minerals, Tungsten Tin

Factors Influence Ore Grinding Mill Efficiency JXSC Mining

2019年5月10日Take a gold mine as an example, reducing ore particle from -15mm to -10mm improve the grinding efficiency from 1150 tons per day to 1500 tons per day, and decrease the steel consumption and electric power consumption by 1.53kg/t to 1.1kg/t and 41.57kWh to 29.2kWh respectively. 2 Milling medium

左蔚然- 福州大学紫金地质与矿业学院 Zijin School of Geology and Mining

2009.09-2013.07 中国矿业大学化工学院 博士研究生 矿物加工工程 . 2005.09-2008.07 中国矿业大学化工学院 硕士研究生 矿物加工工程

Ore Grade Control Procedures

ore grade control in mining ? Grinding Mill China June 17th, 2018 Grade Control Classification of Ore and Waste A Critical Review of Estimation and Simulation Based Procedures ? Learn More ore grade control in December 31st, 2013 Understanding blast movement to optimise grade control designs to promote controlled blast movement

Microwave Pretreatment on Copper Sulfide Ore: Comparison of Ball Mill

2021年7月8日A copper sulfide ore was crushed to 100% passing 3.36 mm, then the crushed product was ground by bed breakage or ball milling. The effect of microwave pretreatment on ball mill grinding and bed breakage was investigated in terms of mineral liberation, particle shape, and floatability.

Buy Ore Ball Mill for Mineral Processing IronGold Ore Ball Mill

Ore Ball Mill Output size: 0.074-0.89mm Motor power: 18.5-480kw Specification (mm): Φ750×750-Φ2700×4500 Applications: It is used for processing various grindable mineral materials, non-ferrous metal mineral processing, new building materials, etc. Email: info@ballmillssupplier Now Product Details Mineral Processing Working

Gold, Silver, Copper, Oil, Gas, Mining # 💥💥[HOT SALE] 1- 20 tph

# [HOT SALE] 1- 20 tph Copper Ore Grinding ball mill # click our official website for【pricedetails】: #...

Flexible milling and grinding solutions that last

Milling and grinding Overview Products Our technology Customer stories Optimal feed material milling and grinding solutions Carefully crafted to meet your milling and grinding needs, our robust and well-designed solutions are