How To Calculate Aggrigate In Crusher Screen Plant

Crusher Efficiency Calculations Mineral Processing

19 行2014年9月15日The screen area needed under the jaw crusher

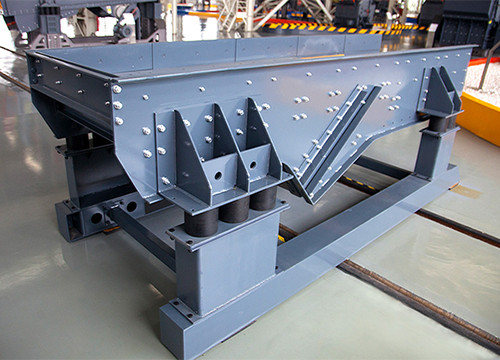

How To Size and Select a Vibrating Screen for an

2022年2月15日The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen.

11.19.1 Sand And Gravel Processing US EPA

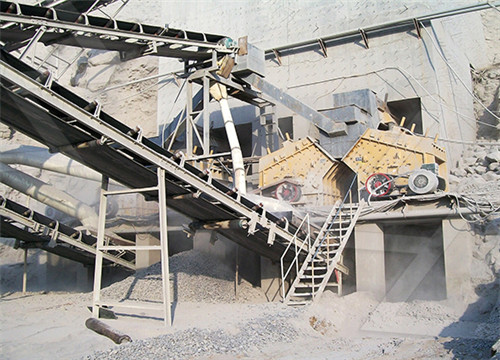

produce crushed aggregate, or to produce manufactured sands. Crushing generally is carried out in one or two stages, although three-stage crushing may also be performed.

Potential To Emit Calculator for Stone Quarrying,

2018年4月10日Potential To Emit Calculator for Stone Quarrying, Crushing, and Screening Plants 8/23/2016 This workbook is designed to calculate the potential to

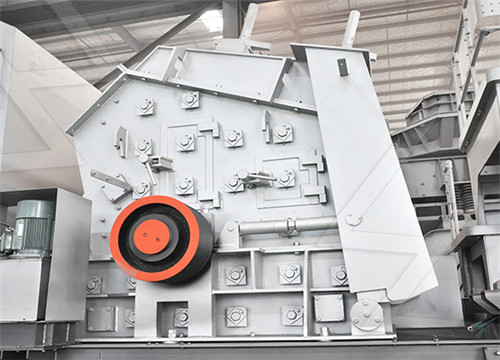

Aggregate Crushing Plant How to Run a Crushing Plant

The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h. if want a higher output, only by increasing the crushing production line.

Aggregates Crushing and Screening Plant PDF

高达$3返现By Screening of crushed stone is necessary. processing the material over a screen that in order to separate the aggregate by size. retains all of the product, the clay and

P&Q University Lesson 8- Screening : PitQuarry

2019年10月11日Scalping screening plants are built to handle the toughest materials but are not as precise as standard screening plants. Material is fed directly onto the

Aggregate Screen Problems and Solutions JXSC Rock

Check the power supply voltage of the vibrating screen. 5. Check the interlock control device of the vibration motor. 6. Remove the end cap of the motor, and check the relative phase angle of the sector is consistent,

A Guide to Mechanical Screening Aggregates Equipment, Inc.

2015年6月11日Do so at your own detriment. To learn more about mechanical screening processes and equipment, contact AEI with specific questions about your processes or

11.19.2 Crushed Stone Processing and Pulverized Mineral

screens and classifiers (for the production of manufactured sand). Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th inch). Crushed stone from the tertiary sizing screen is sized in a vibrating inclined screen (fines screen) with relatively small mesh sizes.

P&Q University Lesson 8- Screening : PitQuarry

2019年10月11日Screening efficiency is calculated as the percentage of the undersize materials passing through the openings divided by the percentage of undersize in the feed. For example, if a screen is only 75 percent efficient, then 25 percent of the material within the desired product range is being rejected with the oversize material.

Crushing Plant Performance Optimization Agg-Net

A typical plant design comprises a number of different production units. A production unit is defined as a machine or larger arrangement used to move, store, separate or crush material in the crushing plant. A production unit can be a crusher, screen, feeder, storage bin, stockpile or conveyor.

sbm/sbm formula of calculate aggrigate in crusher screen plant

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Principles of Screening and Sizing MetallurgistMineral

Principles of Screening and Sizing MetallurgistMineral Processing

Plant simulation software aids crushing and screening Aggregates

2012年3月12日BedRock Software's AggFlowSite is described by the company as the next evolution in plant simulation and optimisation for the global aggregate industry. AggFlowSite delivers the full functionality of the company's traditional Aggflow program to users via the internet, but is specifically intended for unlimited users simulating one

Cost Analysis for Crushing and Screening Part II CORE

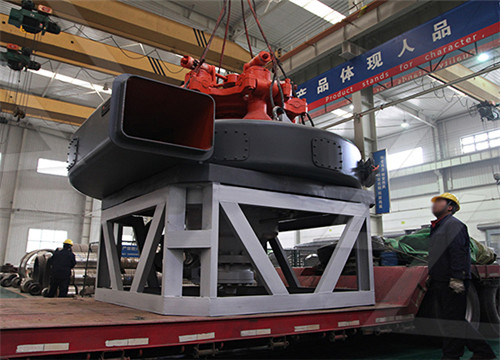

production is concentrated to jaw crushers and cone crushers. 1.1.3.2 Process Flow The process flow described in figure.. is a typical process flow built up by a primary crushing stage, secondary crushing stage. The primary stage usually has a jaw or a gyratory crusher and screening equipment. The secondary have a single or several cone, VSI

Screen Aggregate Equipment For Sale MachineryTrader

2023年3月3日AGGREGATE DESIGNS CO. GRAND JUNCTION, Colorado 81505. Phone: (970) 260-2435. Email Seller Video Chat. 2019 JCI 7' x 20' Triple Deck Portable Screen 50 HP Motor, 48” Underscreen Discharge Conveyor 2 cross conveyors Atlas Electric NEMA Switchgear Panel on Skid-stand (4) Four Run-on Hydraulic Lev See More Details.

Crushing Plant Startup SequenceProcedure

2016年1月26日Start either cone crusher lube pumps and allow 5 seconds for pressure to build up and oil to be circulated through the crusher. Start conveyor #3 (30 second horn will sound).*. Start the cone crusher drive. Start the double deck screen. Once the screen has been started, a 15 second PLC timer will begin timing.

how to calculate aggrigate in thickener screen plant

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Screening Plants: Dirt, Soil, Rock,More Ritchie Bros. Auctioneers

Screens can be dry or wet (water spray system). Screens can exist as part of a screening plant, or a standalone machine like a topsoil screener or dirt screener. Create full-circuit system by pairing a screening plant with a crusher, so raw material is directly harvested and fed through to the screener.

What should I know about a crusher plant? linkedin

2023年3月2日Crusher plants are used in aggregate production, mining, recycling, and in many other industrial processes. They are used to process materials such as rocks, ores, and other aggregates for...

Texas Commission on Environmental Quality

Note: Drops on and off of crushers are accounted for in the crusher emission factors. Drops onto vibrating screens are accounted for in the screen emission factors. The first drops off vibrating screens are NOT accounted for and must be included. Type of Material: Sand, Washed Sand (WS), Aggregate, Washed Aggregate (WA)

Crushing and screening plants stationary, mobile and portable

Metso Outotec Nordplant™ is a stationary crushing and screening plant built using pre-designed modules, which allow quick delivery and easy assembly to get your plant up and running in the time you want. Whether you are building a complete, totally new plant or upgrading your existing plant, pre-designed plants provide high efficiency and

A Guide to Mechanical Screening Aggregates Equipment, Inc.

2015年6月11日Do so at your own detriment. To learn more about mechanical screening processes and equipment, contact AEI with specific questions about your processes or topics that you would like to investigate further. You can also email us at sales@AEIscreens or call (717)-656-2131.

sbm/sbm formula of calculate aggrigate in crusher screen plant

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Principles of Screening and Sizing MetallurgistMineral

Principles of Screening and Sizing MetallurgistMineral Processing

Crushing Plant Performance Optimization Agg-Net

The aim of the optimization is to maximize the gross profit of the crushing plant (ie, income minus production cost). The production cost is calculated using the process accounting method. This is based on a fixed and variable operating cost for all machines.

Plant simulation software aids crushing and

2012年3月12日BedRock Software's AggFlowSite is described by the company as the next evolution in plant simulation and optimisation for the global aggregate industry. AggFlowSite delivers the full functionality of

Screen Aggregate Equipment For Sale

2023年3月3日AGGREGATE DESIGNS CO. GRAND JUNCTION, Colorado 81505. Phone: (970) 260-2435. Email Seller Video Chat. 2019 JCI 7' x 20' Triple Deck Portable Screen 50 HP Motor, 48” Underscreen

Crushing Plant Startup SequenceProcedure

2016年1月26日Start either cone crusher lube pumps and allow 5 seconds for pressure to build up and oil to be circulated through the crusher. Start conveyor #3 (30 second horn will sound).*. Start the cone crusher drive.

Screening Plants: Dirt, Soil, Rock,More Ritchie

Aggregate Screening Equipment Screening Plant New and used screening plants for sale Browse a large selection of screening plants for sale near you from top manufacturers. Popular models include

how to calculate aggrigate in thickener screen plant

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

What should I know about a crusher plant? linkedin

2023年3月2日Crusher plants are used in aggregate production, mining, recycling, and in many other industrial processes. They are used to process materials such as rocks, ores, and other aggregates for...

Crushing and screening plants stationary, mobile and portable

Metso Outotec Nordplant™ is a stationary crushing and screening plant built using pre-designed modules, which allow quick delivery and easy assembly to get your plant up and running in the time you want. Whether you are building a complete, totally new plant or upgrading your existing plant, pre-designed plants provide high efficiency and

Aggregate Screens Screening Equipment Kemper Equipment

The best way to find the right aggregate screeners—as well as screen parts—for your operation is to work with a knowledgeable material handling solutions partner like Kemper Equipment. Discover Our Kemper Equipment Design/Build Capabilities Examples of Kemper Equipment Screening Plant Projects See More Custom Aggregate Screens

Guidance on Emission Factors for the Mining Industry Nevada

2017年5月31日aggregate facilities. These emission factors apply to all inputs to the screen, the screening itself, and all discharges from the screen. The emission factor applies to any type of screen (i.e. single deck, double deck, or triple deck). The BAPC had determined that the use of AP-42 Chapter 11.19.2-2 is appropriate for the gold mining