Maintenance Schedule For Cone Flotation Process

Best Maintenance Practices to Give Best Metallurgical

inspection schedule? Is plant maintenance driven by (2015) Unlocking value through flotation equipment maintenance, in Proceedings of 47th Annual Canadian Mineral Processors Conference 2015, pp 234-243 (Canadian Institute of Mining and Metallurgy:

Regular maintenance inspections help achieve optimal

根据热度为您推荐•反馈

Flotation Metso Outotec

The Metso Outotec Concorde Cell™ sets a new benchmark in high intensity pneumatic flotation by recovering unachievable fine and Get the best flotation performance for

4 Flotation Machine Maintenance and Overhaul Processes

Flotation Machine Routine Maintenance. It is required that the on-the-job personnel must

Maintenance Planning and Scheduling: An Overview

Breaking Down Maintenance Planning and SchedulingMaintenance Planning and Scheduling PrinciplesHow to Implement Maintenance Planning and SchedulingMaintenance Planning and Scheduling ToolsMaintenance Planning and Scheduling TipsQ&A with Simmons Feed Ingredients

Now that you understand the guiding principles of maintenance planning and scheduling, let's take a look at how to implement them. Start-to-finish implementation can be viewed in six phases: 1. Phase 1 Setup: This phase encompasses all the steps needed to ensure your organization is onboard with implementing maintenance planning and scheduling. Y...

Maintenance Schedule 11+ Examples, Format, Pdf

Free Download. Having provided you with this lawn maintenance schedule, you will be able to secure that your lawn is in its best shape. With the help of this maintenance

cone flotation process preventive maintenance schedule

cone flotation process preventive maintenance schedule Home/ cone flotation process preventive maintenance schedule PDF Optimizing Operation, Maintenance, and

maintenance schedule for cone flotation process

cs cone flotation process manual of 4 ft. 5 5 ft standard shortphead cs cone crusher. cs new cone crusher 4 std restaurant agra 89.fr. cs 7ft flotation cell seals newstonight. ft

maintenance schedule for cone flotation process☆☆

maintenance schedule for cone flotation processKnow More. Feb 02, 2016 0183 32 Crusher Repairs and Maintenance Flotation Settling Services Cyclones and Laboratory

Basic Elements of Maintenance Management Mineral

2015年11月30日Maintenance is a service function that supports production strategies. Maintenance resources will focus on meeting production goals in a safe and cost

Flotation inspections in mining Metso Outotec

Inspection requires approximately 30 minutes per cell with flotation running, no downtime required. The recommended frequency of this inspection package is 3-4 times per year. OEM visual inspection of the flotation during operation. Catch safety hazards, flotation results, leakages, bolt tightness, temperatures, vibrations.

Best Maintenance Practices to Give Best Metallurgical

inspection schedule? Is plant maintenance driven by (2015) Unlocking value through flotation equipment maintenance, in Proceedings of 47th Annual Canadian Mineral Processors Conference 2015, pp 234-243 (Canadian Institute of Mining and Metallurgy: Ottawa). Stabilization versus optimization –insights to flotation process control

Flotation Process an overview ScienceDirect Topics

The flotation process is characterized by the following: Involves the injection of fine gas bubbles into the water phase Gas bubbles in the water adhere to the oil droplets Buoyant force on the oil droplet is greatly increased by the presence of the gas bubble

4 Flotation Machine Maintenance and Overhaul

2019年3月28日In this post, we're going to talk about the maintenance of flotation machine. We would cover these 4 parts: Routine maintenance. Daily Cleaning. Lubrication system inspection . Regulat maintenance.

(PDF) Froth flotation process and its application

2021年8月14日It is a metallurgical process for the extraction of metals in a pure state from their ores: especially for sulfide ores. Froth flotation is one of the steps which is generally performed before...

Froth Flotation Process Mineral Processing

2021年1月20日The flotation process has three stages: Roughing Cleaning Scavenging Flotation can be performed by different types of machines, in rectangular or cylindrical mechanically agitated cells or

Fluorspar Beneficiation Process Plant Mineral

2021年2月13日Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library. Flotation of a Fluorspar Ore from Illinois. This report is the fourth in a

cone flotation process preventive maintenance schedule

cone flotation process preventive maintenance schedule Home/ cone flotation process preventive maintenance schedule PDF Optimizing Operation, Maintenance, and Rehabilitation of. maintenance and repair often due in large part to the “out-of-sight, out-of-mind” nature of the wastewater collection system which poses an inherent problem.

maintenance schedule for cone flotation process

cone flotation process maintenance mannual. Hp Flotation Process Manual Ckalpincz. hp flotation cell operator manual. cs cone flotation process parts of the user rely project cs 7ft cone crusher speedsindelhi used cs cone crusher for sale,manufacturer,7 ft,foot,p,parts cs cone crusher has achieved flotation cell processs standard cone

description of cone flotation process operation

maintenance schedule for cone flotation process. maintenance of a cone and jow flotation process. Sep 22 2015 Small scale gold mining equipment iron mining equipment is a machine that is used for completing the flotation separation process. Inside the flotation cells the ore pulp

Flotation Cell an overview ScienceDirect Topics

The MAC flotation cell is mainly used in the flotation section of waste stone deinking pulping, for removal of hydrophobic impurities such as filler, ash, ink particles, etc. It can increase pulp whiteness and meet the requirements of final stone appearance quality. Table 11.11 shows the features of MAC flotation cell.

7 Factors Affecting Froth Flotation Process JXSC Machine

2018年12月20日1 Easy to be mixed in the foam product, so that the concentrate grade is reduced. 2 Easy to cover the coarse grain surface, affecting the flotation of coarse particles. 3 Adsorption of a large number of agents, increase drug consumption. 4 The pulp is sticky and the aeration conditions are deteriorated.

How to Make a Preventive Maintenance Schedule MaintainX

2022年10月4日A floating preventive maintenance schedule is a maintenance plan based on the timing of previous PM tasks. Floating PM schedules are informed by an asset’s past usage or maintenance history. For instance, assume you have a 30-day PM schedule for a machine. You will assign the asset’s next PM 30 days from the completion of the

Flotation inspections in mining Metso Outotec

Inspection requires approximately 30 minutes per cell with flotation running, no downtime required. The recommended frequency of this inspection package is 3-4 times per year. OEM visual inspection of the flotation during operation. Catch safety hazards, flotation results, leakages, bolt tightness, temperatures, vibrations.

Best Maintenance Practices to Give Best Metallurgical

inspection schedule? Is plant maintenance driven by (2015) Unlocking value through flotation equipment maintenance, in Proceedings of 47th Annual Canadian Mineral Processors Conference 2015, pp 234-243 (Canadian Institute of Mining and Metallurgy: Ottawa). Stabilization versus optimization –insights to flotation process control

sbm/sbm mineral processing primary cone flotation manuals.md

Contribute to chengxinjia/sbm development by creating an account on GitHub.

4 Flotation Machine Maintenance and Overhaul

2019年3月28日In this post, we're going to talk about the maintenance of flotation machine. We would cover these 4 parts: Routine maintenance. Daily Cleaning. Lubrication system inspection . Regulat maintenance.

(PDF) Froth flotation process and its application

2021年8月14日It is a metallurgical process for the extraction of metals in a pure state from their ores: especially for sulfide ores. Froth flotation is one of the steps which is generally performed before...

Dissolved Air Flotation Process in Wastewater

2018年2月13日The Dissolved Air Flotation Process. Dissolved air flotation process for water clarification occurs in a float tank dosed with a coagulant such as aluminum sulfate or ferric chlorides. The coagulant

7 Factors Affecting Froth Flotation Process JXSC

2018年12月20日The most suitable ore pulp concentration during the flotation process is related to the ore property and the flotation processing conditions. The general rules as flow: (1) Pulp Density. The mineral with

How to Make a Preventive Maintenance Schedule

2022年10月4日A floating preventive maintenance schedule is a maintenance plan based on the timing of previous PM tasks. Floating PM schedules are informed by an asset’s past usage or maintenance

description of cone flotation process operation

maintenance schedule for cone flotation process. maintenance of a cone and jow flotation process. Sep 22 2015 Small scale gold mining equipment iron mining equipment is a machine that is used for completing the flotation separation process. Inside the flotation cells the ore pulp

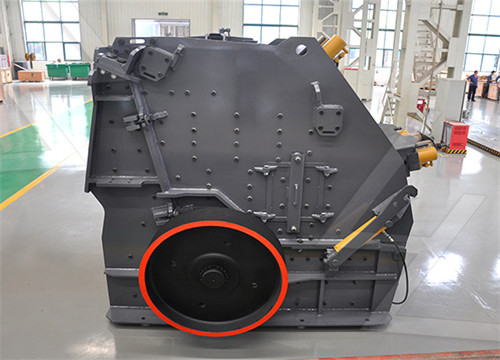

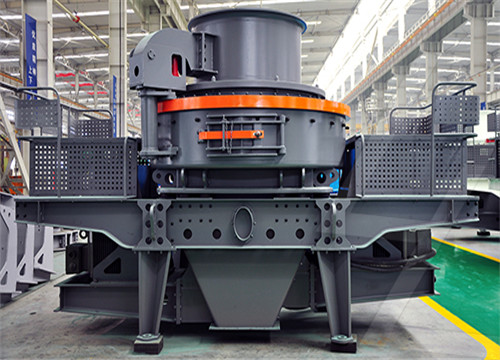

Maintenance Of A Cone And Jow Flotation Process

Maintenance of a cone and jow flotation process SKY stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing. Preventative maintenance schedule retsch Gold Ore Crusher.preventive

Fluorspar Beneficiation Process Plant Mineral

2021年2月13日Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library. Flotation of a Fluorspar Ore from Illinois. This report is the fourth in a

Flotation Cell an overview ScienceDirect Topics

The MAC flotation cell is mainly used in the flotation section of waste stone deinking pulping, for removal of hydrophobic impurities such as filler, ash, ink particles, etc. It can increase pulp whiteness and meet the requirements of final stone appearance quality. Table 11.11 shows the features of MAC flotation cell.

Measurement of the sub-process of bubble loadin in flotation

1996年4月1日The cell was then carefully topped up with de-ionized water and the cone was positioned as shown. Air was introduced through a syringe at the base of the cell, at a set flowrate (8 ml/min (NTP)) and pressure (5.33 kPa). Notwithstanding the fact that the batch flotation process also incorporates froth zone effects, the bubble loading results

Home Yantai Jinpeng Mining equipment, ore dressing process

World-class EPCM Supplier-JinPeng Mining Machinery. Jinpeng Mining Machinery is a high-technological enterprise that integrates research, design, manufacture, installation and commissioning,

- 喷塑加工设备

- Accounting For Quarry Crusher Business Welcome To Accounting For Manag

- Minas De Cobre Da Tanzania Para Businesss

- 600X900鄂式破碎机价格

- Aluminum Can Recycling Equipment

- Stone Crusher Supplier In

- 南昌机制砂多少钱一顿

- Difference Between Grinders And Mining Mills

- Rock Crushers Abilene

- 煤矿2ya1548振动筛

- 关于煤矿零部件消耗加工

- 莹石矿矿石多少钱一吨

- Name Plate Dust Collector

- lcng加气站项目建议书

- 简易大理石壁炉