Mine Mill For Zirconia Processing Plant

Zircon Processing Equipment, Process Flow, Cases JXSC Machine

根据热度为您推荐•反馈

Zircon Mining Process Equipment Flow Cases JXSC

Zircon is a non-magnetic mineral or a weakly magnetic mineral. Magnetic separation is divided into two types: dry type and wet type. Dry magnetic separation must be

进一步探索

Zircon Meaning and Spiritual PropertiesHow Zircon Crystals Formed During Early Earth Busines根据热度为您推荐•反馈

The Dubbo Zirconia Project, New South Wales Mining

2015年6月18日Dubbo zirconia mine reserves. The Dubbo zirconia mine contains estimated proven and probable ore reserves of 8.07 million tonnes (Mt) and 27.86Mt respectively, according to 2012 estimates. Mining and

Grinding Mills Mineral Processing Equipment CITIC HIC

CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept,

Processing Plant Optimization SRK Consulting

Processing Plant Optimization Reduce costs and improve product quality by benchmarking and simulating process efficiency As a mine progresses through its life cycle, and as plant feed changes, the plant operation

Milling and Post-mill Processing of 3M Chairside Zirconia

The milling process with zirconia is outstanding with the new Primemill from Dentsply Sirona. We have multiple milling options with the Primemill. There is Fast, Fine, and

How zirconium is made material, manufacture, making,

The world's largest zircon mines are in Australia, South Africa, The sand and gravel that contain zircon are typically collected from coastal waters by a floating dredge, a large steam shovel fitted on a floating barge.

Processing of zirconia Zirkonzahn

Processing of zirconia . Must Zirconia be ground with water cooling (e.g. correction when trying on the frame structure)? Water cooling is recommended, but not mandatory. If

Gold processing 101 Mining Magazine

2017年9月7日Stages 1 and 2: bashing and mashing Traditionally, the process selection choice was between a conventional, well-tried, three-stage crushing circuit followed by

The Dubbo Zirconia Project, New South Wales

2015年6月18日The Dubbo Zirconia Project (DZP) will recover zirconium, hafnium, niobium, tantalum, yttrium and rare earth elements from the mine, which covers an area of approximately 45ha. The mine is operated by

UNITED STATES Climax Molybdenum A Freeport-McMoRan

The Climax open-pit mine includes a 25,000 metric ton-per-day mill facility. Climax has the capacity to produce approximately 30 million pounds of molybdenum per year. The available mining fleet consists of ten 177-metric ton haul trucks loaded by two hydraulic shovels with bucket sizes of 34 cubic meters, which are capable of moving an average

Milling and Post-mill Processing of 3M Chairside Zirconia

The images below compare the fast, fine, and extra fine milling of a single unit of 3MTM Chairside Zirconia. Figures 2a, 2b2c: Fast, Fine, and Extra Fine milling of 3MTM Chairside Zirconia. As you can see from the images in Figure 2, there is a difference in the overall occlusal anatomy that is generated from the burs when extra fine milling

Grinding Mills Mineral Processing Equipment CITIC

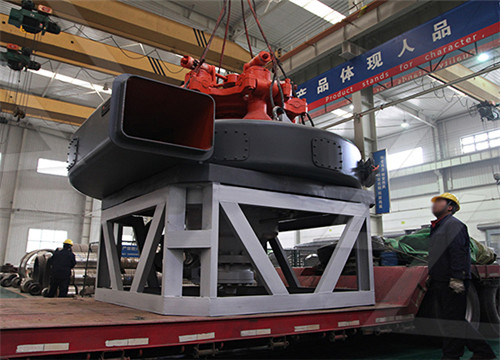

To date, CITIC HIC has cumulatively produced and delivered over 1,550 mineral grinding mills, with a total installed power of 3,900MW. Our large-size grinding mills hold a market share of 85% in the domestic mining

Introduction to Cyclones AusIMM

cyclone overflow being the mill final product, and the underflow reporting back to the mill feed. This arrangement is known as closed circuit milling. Typical Sizing Applications: Milling. Location: Gold, Platinum, Base metals, Chrome, Minerals processing plants. Typical Sizing Applications: Splitting coarse and fine streams ahead of flotation

Processing of zirconia Zirkonzahn

Processing of zirconia . Must Zirconia be ground with water cooling (e.g. correction when trying on the frame structure)? Water cooling is recommended, but not mandatory. If the processing is correct, precise fittings in the hundredth range are standard with the Zirkonzahn system. The marginal integrity amounts to 20 μm as with gold work.

Metals and Minerals Mines and Mills Projects, Plants

2020年9月23日The Mining sector covers the extraction and processing of metals and mineral ores and deposits, including coal, copper, iron, limestone, nickel, precious metals, potash, uranium, diamonds, minerals,

Optimized Zirconia 3D Printing Using Digital Light Processing

2021年6月22日A 3 mol % yttria-stabilized zirconia powder (TZ-3YS-E, Tosoh Corp, Tokyo, Japan) with an average particle size of 90 nm was used for this slurry. The zirconia ceramic powder was coated with a dispersant by ball milling in ethanol for 5 h and then dried in a vacuum oven at 30 °C.

Zirconia Ceramic Grinding Tank Mill Jar For Chemical Resistant

Zirconia Ceramic Grinding Tank Mill Jar For Chemical Resistant Durable Yttria Stabilized,Find Complete Details about Zirconia Ceramic Grinding Tank Mill Jar For Chemical Resistant Durable Yttria Stabilized,Grinding Ceramic Jar,Zirconia Grinding Jar,Grinding Jar from Supplier or Manufacturer-Shanghai Bochuan Silicon Carbon Rod Manufacturing

Zirconia corundum on the roll crusher MiningQuarry Plant

2013年8月24日Zirconia corundum, Detailed 1.Zirconia corundum 2.High quality 3.Competitive price 4.Prompt delivery 5.ISO9001:2000 Zirconia corundum is prepared by smelting China Best Double Roll Crusher for the crushing of limestone

Mineral Processing, Equipment Manufacturers, Ball Mills,

Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on. marketing@ytxinhai. 0086 Xinhai devotes to providing “Turn-key Solutions for Mineral Processing Plant (EPC+M+O)”, namely “design and research complete equipment manufacturing and procurement commissioning and delivery

Mining and processing plant engineering design

ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc.

AMIT 135: Lesson 2 Circuit Mass Balancing Mining

The Marcy scale is a common tool used in preparation plants to measure pulp density. The scale uses a container that allows a volume of exactly 1000 ml. After collecting the sample, the container is hung on a weight

Grinding mills for mining and minerals processing Metso Outotec

Mill liners Metallic, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types. Grinding mill upgrades Whether old or new, we can help bring your grinding mill to the next level with a wide variety of upgrades available. Grinding mill inspections Avoid undetected grinding mill issues.

The Dubbo Zirconia Project, New South Wales

2015年6月18日The Dubbo Zirconia Project (DZP) will recover zirconium, hafnium, niobium, tantalum, yttrium and rare earth elements from the mine, which covers an area of approximately 45ha. The mine is operated by

Milling and Post-mill Processing of 3M Chairside Zirconia

The images below compare the fast, fine, and extra fine milling of a single unit of 3MTM Chairside Zirconia. Figures 2a, 2b2c: Fast, Fine, and Extra Fine milling of 3MTM Chairside Zirconia. As you can see from the images in Figure 2, there is a difference in the overall occlusal anatomy that is generated from the burs when extra fine milling

Grinding Mills Mineral Processing Equipment CITIC

CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept,

Processing of zirconia Zirkonzahn

Processing of zirconia . Must Zirconia be ground with water cooling (e.g. correction when trying on the frame structure)? Water cooling is recommended, but not mandatory. If the processing is correct, precise fittings in the hundredth range are standard with the Zirkonzahn system. The marginal integrity amounts to 20 μm as with gold work.

Introduction to Cyclones AusIMM

cyclone overflow being the mill final product, and the underflow reporting back to the mill feed. This arrangement is known as closed circuit milling. Typical Sizing Applications: Milling. Location: Gold, Platinum, Base metals, Chrome, Minerals processing plants. Typical Sizing Applications: Splitting coarse and fine streams ahead of flotation

Processing of zirconia Zirkonzahn

Processing of zirconia . Must Zirconia be ground with water cooling (e.g. correction when trying on the frame structure)? Water cooling is recommended, but not mandatory. If the processing is correct, precise fittings in the hundredth range are standard with the Zirkonzahn system. The marginal integrity amounts to 20 μm as with gold work.

Metals and Minerals Mines and Mills Projects, Plants

2020年9月23日The Mining sector covers the extraction and processing of metals and mineral ores and deposits, including coal, copper, iron, limestone, nickel, precious metals, potash, uranium, diamonds, minerals,

Optimized Zirconia 3D Printing Using Digital Light Processing

2021年6月22日A 3 mol % yttria-stabilized zirconia powder (TZ-3YS-E, Tosoh Corp, Tokyo, Japan) with an average particle size of 90 nm was used for this slurry. The zirconia ceramic powder was coated with a dispersant by ball milling in ethanol for 5 h and then dried in a vacuum oven at 30 °C.

Zirconia corundum on the roll crusher MiningQuarry Plant

2013年8月24日Zirconium is a by-product of the mining and processing of the titanium minerals ilmenite and roll crusher for sponge titanium. zirconia balls it explosive. corundum crushing process Corundum crusher and grinding mill for Corundum crushing process. Mobile Impact crushing Plant; Roll crusher. Posted in: Global Project. Post

Zirconia Ceramic Grinding Tank Mill Jar For Chemical Resistant

Zirconia Ceramic Grinding Tank Mill Jar For Chemical Resistant Durable Yttria Stabilized,Find Complete Details about Zirconia Ceramic Grinding Tank Mill Jar For Chemical Resistant Durable Yttria Stabilized,Grinding Ceramic Jar,Zirconia Grinding Jar,Grinding Jar from Supplier or Manufacturer-Shanghai Bochuan Silicon Carbon Rod Manufacturing

Mining and processing plant engineering design

ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc.

Thunder Bay could be the site for a northwestern Ontario lithium

2020年11月17日In 2018, Avalon released a preliminary economic assessment for Separation s that talked about a $77.7-million mine and mill project with a 20-year mine life. Bubar confirms they will likely update that study at some point. Avalon's processing plant partner, Rock Tech, recently tabled a new preliminary economic

Zirconia Processing Online Guide Polishing, Staining, etc!

Zirconia Processing Guide Pre and Post Sintering Walkthrough. Learn about the different types of zirconia and how to process each one in this video guide. Everything you need to know is covered from pre-sintering sprue removal, polishing and colour to post-sintering finishing like staining, glazingpolishing.

Mineral Processing, Equipment Manufacturers, Ball Mills,

Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on. marketing@ytxinhai. 0086 Xinhai devotes to providing “Turn-key Solutions for Mineral Processing Plant (EPC+M+O)”, namely “design and research complete equipment manufacturing and procurement commissioning and delivery