Dry Wet Magnetic Separator For Benificiation

Dry Iron Ore Beneficiation ST EquipmentTechnology

Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic

(PDF) Recovery of magnetite from dry crushed feed using

2019年9月29日The aim of this study is to examine the performance of wet drum magnetic separation on the recovery of magnetite from dry crushed feed. The steel industry has depended on iron (Fe) concentrate

Dry coal preparation without the use of water • STEINERT

Dry coal beneficiation with sorting systems; wet drum magnetic separators for traditional processing (de-stoning for greater efficiency) Even today, traditional coal beneficiation

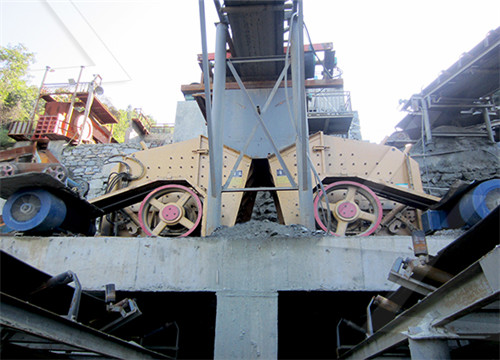

For dry and wet processing Low Intensity Magnetic

stationary magnet array. The Low intensity magnetic separators are available in several types for vast number of duties and could be seen as split into two categories, i.e. dry

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy

Dry or Wet Magnetic Separator? Mining-pedia

2018年11月7日Wet magnetic separator is a magnetic separator commonly used in iron ore dressing plants. It can be used not only for sorting operations, but also for replacing the magnetic dewatering tank

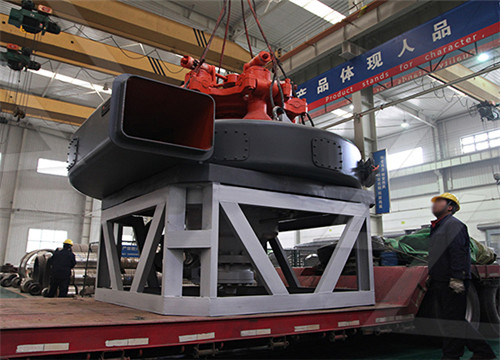

Dry magnetic separator, Beneficiation Equipment Dry ZENITH

2.They are particularly suitable for primarily separating low-grade ores, improve raw ore grade for feeding mills and lower magnetic separating costs. 3.The magnet system of

Dry magnetic separator, wet magnetic separator,

Dry magnetic separator, wet magnetic separator, permanent ma Mineral Processing Service Process To provide you with one-stop solution in the construction of the plant!

Dry Magnetic Separator Magnets By HSMAG

Introduction and function of Dry magnetic separator BY HSMAG. The dry magnetic separator is commonly used iron ore and manganese ore beneficiation equipment. It is the mainstream strong magnet separator,

Design and Construction of a Magnetic Separator for Dry

The aim of the project is to develop a 150W magnetic separator for the dry beneficiation of magnetic minerals. The main objectives include to: increase the metal content of the ore; reduce the gangue content so as to lower the slag formed in extraction of metal and decrease the thermal energy to separate liquid metal form mineral.

Mineral beneficiation of nepheline syenite with combination

the dry magnetic separation should be used to eliminate iron bearing minerals at coarser grain sizes. However, it is known from literature that wet high intensity magnetic separation must be used to

Beneficiation of South African chromite tailings using

The gravity separation process is the main beneficiation process used to recover chromite mineral. characterised with the objective of recovering fine and ultrafine chromite using wet magnetic separation process. MMME 138-2 2. Materials and Methods Particle size distribution analysis was carried out on a dry screen shaker and the

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

(PDF) Recovery of magnetite from dry crushed feed

2019年9月29日The studies showed that, dry comminution prior to wet magnetic separation has the potential to reduce the water requirements in magnetite beneficiation as well as improved mineral...

For dry and wet processing Low Intensity Magnetic

stationary magnet array. The Low intensity magnetic separators are available in several types for vast number of duties and could be seen as split into two categories, i.e. dry separation and wet separation. The dry models are intended predominantly for material 2 to 200 mm in dry or nearly dry state like crushed iron ore.

The PTMS magnetic separator control technology realizes system

The Potash feldspar PTMS magnetic separator system uses computer control technology to automate and centrally monitor large-scale construction systems. Push the technical level of the construction system to a new height; The contactless system is adopted to improve the flexibility of the control system, which can adapt to the changeable

dry drum magnetic separator quality dry drum magnetic separator

Dry Magnetic Separator for Sale Features Dry drum magnetic separators are the perfect choice for the recovery of iron ore in dry areas such as Chile, Mongolia, the Southwest of the US, the Northwest region of China and many other dry or desert areas. The application of a dry drum separator lowers the beneficiation plants reliance on water and is

dry magnetic separator quality dry magnetic separator for sale

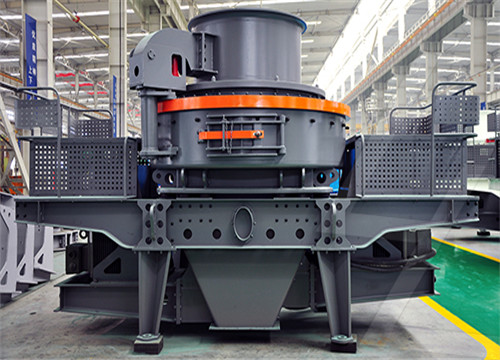

Dry Magnetic Separator Machine Ore River Sand Gold Fluorite Beneficiation Plant Magnetic separator introduction: The iron ore dry magnetic separator is a piece of mineral processing equipment used to recover ferromagnetic materials. It is fit for processing fine, feebly magnetic materials, such as magnetite, pyrrhotite, ilmenite and other

2023 Wet Magnetic ore washing, beneficiation and purification

2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Find Complete Details about 2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Magnetic Separator Separator Magnet

Magnetic Separators Multotec

5 top benefits of the Wet Drum magnetic separators Prevents large particles from blocking the tank Allows optimal setting of the high-performance magnetic arc relative to the discharge lip, thus, allowing

Economic and Socio-Environmental Benefits of Dry Beneficiation

2020年10月26日In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energy-efficient technologies for dry processing of magnetite ores. The present study investigates the economic and socio-environmental benefits of applying these technologies in

Assessing the performance of a novel pneumatic magnetic separator for

2020年9月1日Comparative studies between an innovative dry magnetic separator and wet magnetic separators, i.e., DTR and DMS, were performed. Before that, the effect of selected operational parameters (air velocity, magnet disc speed, and feed particle sizes) on the performance of the PMS was investigated to optimise it. The low intensity dry

Dry coal preparation without the use of water • STEINERT

The entire product palette for optimal coal beneficiation Dry coal beneficiation with sorting systems; wet drum magnetic separators for traditional processing (de-stoning for greater efficiency) Even today, traditional coal beneficiation is performed using coal washing with large amounts of water.

Economic and Socio-Environmental Benefits of Dry Beneficiation

2020年10月26日This study aims to investigate the potential economic benefits of a conceptual dry beneficiation flowsheet (Flowsheet 1) of hard, fine-grained magnetite ore involving the SFC and PMS and to compare the outcome with a conceptual wet beneficiation flowsheet (Flowsheet 2) for the same ore.

Design and Construction of a Magnetic Separator for Dry

The aim of the project is to develop a 150W magnetic separator for the dry beneficiation of magnetic minerals. The main objectives include to: increase the metal content of the ore; reduce the gangue content so as to lower the slag formed in extraction of metal and decrease the thermal energy to separate liquid metal form mineral.

Beneficiation of South African chromite tailings using

The gravity separation process is the main beneficiation process used to recover chromite mineral. characterised with the objective of recovering fine and ultrafine chromite using wet magnetic separation process. MMME 138-2 2. Materials and Methods Particle size distribution analysis was carried out on a dry screen shaker and the

(PDF) Recovery of magnetite from dry crushed feed

2019年9月29日The studies showed that, dry comminution prior to wet magnetic separation has the potential to reduce the water requirements in magnetite beneficiation as well as improved mineral...

For dry and wet processing Low Intensity Magnetic

stationary magnet array. The Low intensity magnetic separators are available in several types for vast number of duties and could be seen as split into two categories, i.e. dry separation and wet separation. The dry models are intended predominantly for material 2 to 200 mm in dry or nearly dry state like crushed iron ore.

Mineral beneficiation of nepheline syenite with combination

the dry magnetic separation should be used to eliminate iron bearing minerals at coarser grain sizes. However, it is known from literature that wet high intensity magnetic separation must be used to

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

The PTMS magnetic separator control technology realizes system

The Potash feldspar PTMS magnetic separator system uses computer control technology to automate and centrally monitor large-scale construction systems. Push the technical level of the construction system to a new height; The contactless system is adopted to improve the flexibility of the control system, which can adapt to the changeable

Dry magnetic separator, wet magnetic separator, permanent ma

Dry magnetic separator, wet magnetic separator, permanent ma Mineral Processing Service Process To provide you with one-stop solution in the construction of the plant! Mineral Processing Experiment Through The Analysis of The Pre-concentration Test, It is Used To Verify The Mineral Selectivity And Find Excellent Mineral Processing Methods.

2023 Wet Magnetic ore washing, beneficiation and purification

2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Find Complete Details about 2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Magnetic Separator Separator Magnet

Assessing the performance of a novel pneumatic magnetic separator for

2020年9月1日Comparative studies between an innovative dry magnetic separator and wet magnetic separators, i.e., DTR and DMS, were performed. Before that, the effect of selected operational parameters (air velocity, magnet disc speed, and feed particle sizes) on the performance of the PMS was investigated to optimise it. The low intensity dry

dry drum magnetic separator quality dry drum magnetic separator

Dry Magnetic Separator for Sale Features Dry drum magnetic separators are the perfect choice for the recovery of iron ore in dry areas such as Chile, Mongolia, the Southwest of the US, the Northwest region of China and many other dry or desert areas. The application of a dry drum separator lowers the beneficiation plants reliance on water and is

dry magnetic separator quality dry magnetic separator for sale

Dry Magnetic Separator Machine Ore River Sand Gold Fluorite Beneficiation Plant Magnetic separator introduction: The iron ore dry magnetic separator is a piece of mineral processing equipment used to recover ferromagnetic materials. It is fit for processing fine, feebly magnetic materials, such as magnetite, pyrrhotite, ilmenite and other

Magnetic Separator Fodamon Machinery

This series of magnetic separators are suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm, and also for iron removal of coal, non-metallic ore, building materials and other materials.

- Rock Crusher Mobile Specifications And How Much

- Gyratory Crushing Equipment Cylinder Upper Bushing Manufacturer

- 云南矿石加工机器市场

- sp500破碎机

- 吨石灰石破碎生产线

- How To Make Disk Mill

- 吉林白城钼矿

- 粉水国外价格

- Molino Automatico De Martillos Con Criva

- 河北巩义粉碎机厂13027712563

- 技术支持 中企动力机械

- 石材加工需要哪些设备

- 矿用超细磨

- Made In Shanghai The Best Sand Washing Machine Price

- 锤式粉碎机有多少规格