Gyratory Crusher Surge Pocket

CG800i Gyratory Crushers — SRP

根据热度为您推荐•反馈

Industrial Solutions Gyratory crushers ThyssenKrupp

The bevel gear and pinion of the crusher are both of a cyclo-palloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed. A B C C D F E I J

Rock Crushing Rule of Thumb Mineral Processing

Crusher SelectionCrusher DesignCrusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application

The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S...The desired grizzly opening for an underground jaw crusher is equal to 80% of the gape of the crusher. Source: Jack de la VergneThe maximum feed size for a jaw crusher should be about 85% of the gape. Source: Arthur Taggart展开选择时,新内容将添加到焦点当区域上方在911metallurgist上查看更多信息

Gyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily

Heavy duty, maintenance-friendly Gyratory Crusher

The Gyratory Crusher “NT” incorporates all of the TC’s heavy-duty design features (Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing,

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary

Primary Crusher (Gyratory) Surge Bin Below the Mantle

Home Industries MineralsMining Primary Crusher (Gyratory) Surge Bin Below the Mantle Application Conditions: Water dust suppression sprays, dust, build-up. Level Technology Choice: To detect a reversing truck (a)

Gyratory Crusher Explained saVRee

Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Cone and gyratory crusher considerations. Make sure the cone crusher does not get ring bounce or chatter. Variable flow controlled by level sensors will ensure

CG800i Gyratory Crushers — SRP

CG800i crushers offer excellent reliability and saferfaster maintenance up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough

Metso SUPERIOR® gyratory crushers Metso

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine Metso’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy

Gyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily

Superior™ MKIII 62-75 primary gyratory crusher

The core of the Superior™ MKIII 62-75 primary gyratory crusher is a robust design. Resistant U-shaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as

Gyratory Crushers Dorr-Oliver Eimco PDF

This entire Gyratory Crusher is engineered from the ground up with Safety and Maintenance in mind. The feature that distinguishes the "TS" design from other Gyratory r Crushers is * that the "TS" machine is designed to

Gold Ore Roasting Plant Mineral Processing

2016年5月31日The surge pocket variable live operating capacity ranges between 60 and 100 tons. The gyratory crusher product conveyor discharges onto the cone crusher feed conveyor (502). Primary crushed

Rock Crushing Process in Mining Mineral

2015年7月18日The 1067 mm gyratory crusher has essentially the same capacity as the 1600 mm (1600 x 2000) jaw crusher. Gyratory crushers tend to offer more flexibility than most other crushers with respect to

DEPARTMENT OF ENVIRONMENTAL CONSERVATION AIR

2023年1月1日41 Gyratory Crusher 11-CRU-100 5,100 ton/hr 42 Gyratory Crusher Surge Pocket 11-BIN-150 5,100 ton/hr 43 Gyratory Crusher Apron Feeder 11-FEE-150 5,100 ton/hr 44 Gyratory Crusher Discharge Conveyor 11-CVB-100 5,100 ton/hr 45 Stockpile Feed Conveyor 14-CVB-200 5,100 ton/hr 46 . Apron Feeder 14-FEE-200 :

Primary Crusher (Gyratory) Surge Bin Below the Mantle

Home Industries MineralsMining Primary Crusher (Gyratory) Surge Bin Below the Mantle Application Conditions: Water dust suppression sprays, dust, build-up. Level Technology Choice: To detect a reversing truck (a)

Superior™ MKIII Series primary gyratory crushers Metso Outotec

Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to the Metso Outotec Outotec Superior™ MKIII crushers brings up to 70% reduction in downtime. Crusher maintenance downtime has also produced a significant

选煤专业英语词汇汇总.._百度文库

30碎矿仓-crushed ore pocket 31粉碎产品-crushed product 32粉碎粒度-crusher size 33粉碎腔-crushing cavity rod mill旋转(圆锥)形破碎机Gyratory crusher ; cone crusher准备破碎3)Auxiliary breaking preliminary breaking; auxiliary crushing; preliminary crushing最终破碎Finished breaking; finished crushing; final

Crusher an overview ScienceDirect Topics

The Gyradisc crushers have head diameters from around 900-2100 mm. These crushers are always operated in choke feed conditions. The feed size is less than 50 mm and therefore the product size is usually less than 6-9 mm. View chapter Purchase book Mineral Processing Swapan Kumar Haldar, in Mineral Exploration (Second Edition), 2018 13.3.1

CG850 Primary Gyratory Crusher With Large Feed

CG830i crusher offer excellent reliability and saferfaster maintenance up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical spider bearing offers 5 times longer wear life than competing spider bushing design.

TECHNICAL INNOVATION'S EXTEND LIFE OF cvdyn

conveyor from the in-pit gyratory crusher to the mill feed stockpile. The primary crusher has a -200 OSS. The design flow rate is 6500 t/h, with a 4 m/s belt The belt feeder speed was linearly regulated to the crusher surge pocket level. A low pocket level shut down the feed. High rock turbulence,

Superior™ MKIII Series primary gyratory crushers Metso Outotec

Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to the Metso Outotec Outotec Superior™ MKIII crushers brings up to 70% reduction in downtime. Crusher maintenance downtime has also produced a significant

CG850 Primary Gyratory Crusher With Large

CG830i crusher offer excellent reliability and saferfaster maintenance up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough

Metso SUPERIOR® gyratory crushers Metso

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine Metso’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy

Superior™ MKIII 62-75 primary gyratory crusher

The core of the Superior™ MKIII 62-75 primary gyratory crusher is a robust design. Resistant U-shaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as

Clearing Blocked Crushers Health and Safety Authority

A gyratory crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear resistant mantle, and the enclosing concave hopper. As oversize rock enters the top of the gyratory crusher, it becomes wedged and squeezed between the mantle and hopper. Large pieces of rock are broken once, and then fall

Gyratory Crushers Dorr-Oliver Eimco PDF

This entire Gyratory Crusher is engineered from the ground up with Safety and Maintenance in mind. The feature that distinguishes the "TS" design from other Gyratory r Crushers is * that the "TS" machine is designed to

Gold Ore Roasting Plant Mineral Processing

2016年5月31日The surge pocket variable live operating capacity ranges between 60 and 100 tons. The gyratory crusher product conveyor discharges onto the cone crusher feed conveyor (502). Primary crushed

Rock Crushing Process in Mining Mineral

2015年7月18日The 1067 mm gyratory crusher has essentially the same capacity as the 1600 mm (1600 x 2000) jaw crusher. Gyratory crushers tend to offer more flexibility than most other crushers with respect to

TECHNICAL INNOVATION'S EXTEND LIFE OF cvdyn

conveyor from the in-pit gyratory crusher to the mill feed stockpile. The primary crusher has a -200 OSS. The design flow rate is 6500 t/h, with a 4 m/s belt The belt feeder speed was linearly regulated to the crusher surge pocket level. A low pocket level shut down the feed. High rock turbulence,

选煤专业英语词汇汇总.._百度文库

30碎矿仓-crushed ore pocket 31粉碎产品-crushed product 32粉碎粒度-crusher size 33粉碎腔-crushing cavity rod mill旋转(圆锥)形破碎机Gyratory crusher ; cone crusher准备破碎3)Auxiliary breaking preliminary breaking; auxiliary crushing; preliminary crushing最终破碎Finished breaking; finished crushing; final

Heavy duty, maintenance-friendly Gyratory Crusher

The Gyratory Crusher “NT” incorporates all of the TC’s heavy-duty design features (Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components) and focuses on coupling these historical characteristics with updated maintenance-friendly features.

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日A gyratory crusher uses a mantle that gyrates, or rotates, within a concave bowl. As the mantle makes contact with the bowl during gyration, it creates compressive force, which fractures the rock. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. Gyratory crushers often are built into a cavity in

Gyratory Crusher l Introduce, Working Principle JXSC Mine

The gyratory stone crusher changes the size of the ore discharge port is using to adjust the rise or fall of movable cone. Cone crushers adjust the height of the fixed cone to realize the adjust of the width of the ore discharge mouth. Get more stone crusher machine price, contact us. Previous Post Next Post

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Follow the steps outlined in this article to achieve the best crushing efficiency for jaw, cone, gyratory and impact crushers and to ultimately increase profits and reduce fines production. By taking these steps, you’re reducing the amount fines produced and adding dollars to your pocket. Information for this article courtesy of McLanahan Corp.

- 不同比重如何定量给料机

- 2014年4月23日的法制报版临汾石亦军

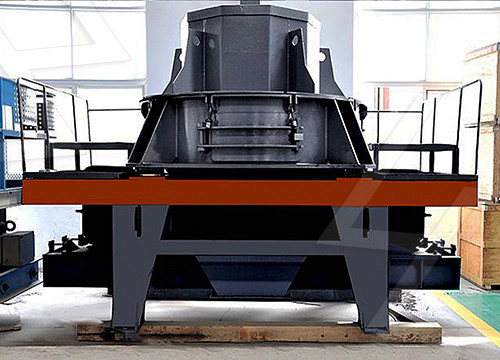

- 平安碎石生产线

- Crushing Equipment Suppliers For Quartz Sand Bali?Indonesia

- 甲板筛分机

- 矿石破碎机械厂家哪家的设备好设备产品目录

- Antifraudinternational Next Of Kin Copper Mining 2012

- 2011 Most Popular Use Advanced Mobile Crusher In China

- 链条锅炉怎么烧蒙煤

- 振动给料机上橡胶减震弹簧的作用

- 石墨棒生产厂

- 磷铁矿石的功效

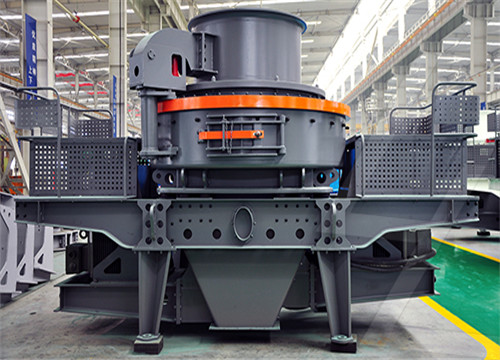

- 粗砂打成细沙设备

- 抚顺水泥厂生产工艺

- 移动式制砂机组