What Is The Function Of Dynamic Separator Of Raw Mill

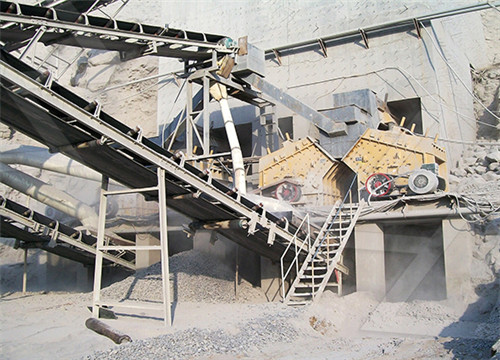

Power savings by bypassing the dynamic separator in a raw mill

The application of this model to a raw mill circuit indicates that although the circulating load of the separator alone varies in the range 60-120% of the fine product from the separator, it is only 16-25% of the fresh feed. This suggested conversion of the existing closed-circuit

Rawmill Wikipedia

OverviewHistoryMaterials groundControl of minor elementsWet rawmillsDry rawmills

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the eff

Cement Milll Separator Cyclone Air Separator in Cement

The function of the separator is to separate the fine-sized particles from the coarse-sized particles, so as to avoid material condensation and over grinding in the mill, and improve

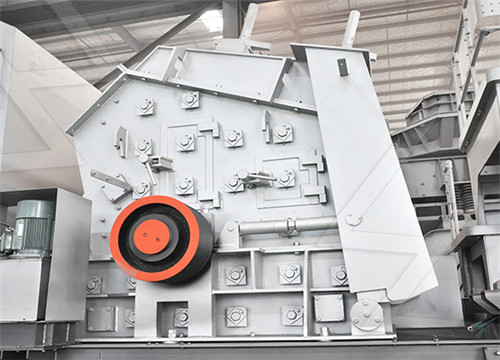

DEG Dynamic Separator Dal Technic Machinery A

Dynamic separator is a device that separates course and fine materials as reject and product. It can be used in many areas of industry such as cemet, energy, mine, metals and agriculture. Dynamic separator consists of

DEG Dynamic Separator Dal Machinery

Dynamic separator is a device that separates course and fine materials as reject and product. It can be used in many areas of industry such as cemet, energy, mine, metals

Dynamic separator efficiency, SEPOL, O-Sepa, Sepax etc

online cement plant live calculator for dynamic separator calculation, Efficiency on Coarse basis, fine basis, efficiency against residues of mill output separator input and return

Cement Plant: Raw Mill Separator • SAMSON SAMSON GROUP

A significant damage to the raw mill dynamic separator was prevented. By fixing a small problem ahead of time, a greater problem causing shutdown and lost production was

Separators in the cement industry

The separator material feed is carried out mechanically by means of suitable continuous conveyors. Fines are conveyed by air in external cyclones or directly to a bag filter. The main separating device is a

what is the function of dynamic separator of raw mill

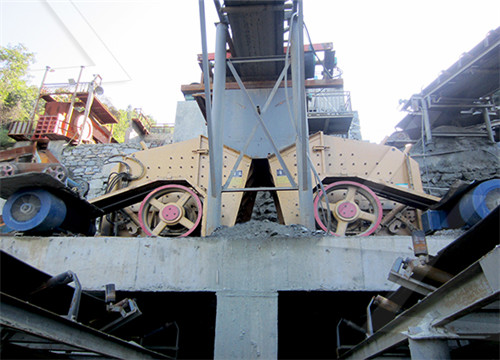

mill (CM) is fed with raw materials. The milled product is fed via a recycle elevator to a dynamic separator. The high fineness stream of the separator constitutes the final

what is the function of dynamic separator of raw mill

raw mill separator drag force Home / raw mill separator drag force . raw mill separator drag force. Separator sizing - PetroWiki. The balance of drag and buoyancy is given as

Dynamic Separator Manufacturer -Greenfield Tech

2023年3月1日A Dynamic Separator is an industrial machine which sorts materials by a combination of size, shape, and density. It works by injecting the material stream to be sorted into a chamber which contains a column

Dynamic separator efficiency, SEPOL, O-Sepa, Sepax etc

online cement plant live calculator for dynamic separator calculation, Efficiency on Coarse basis, fine basis, efficiency against residues of mill output separator input and return coarse material

Separators in the cement industry

This separator is from KHD Humboldt Wedag AG. The V-separator is generally used with a pregrinding system (Roller Press). Applications mainly for raw meals, clinker and slag. The main objective of this

SAM GUARD • SAMSON USA

Cement plant: raw mill separator Broken tooth of dynamic separator in raw mill. SAM GUARD gave pinpointed alerts, directing maintenance staff to the exact separator. The overlooked defective tooth could be replaced. A significant damage to the dynamic separator of the raw mill was prevented. ? Go to case study

Dynamic Separator Karthi PDF Mill (Grinding) Force Scribd

separator will treat them as a big particle. The return of the agglomerates for further grinding. will hamper the process and reduce the overall. efficiency. The separator is constructed in such a way that it. will ensure a high degree of dispersion of the. individual particles in all the agglomerates.

ATOX coal mill

The ATOX coal mill is suited for various installation types, whether inert or non-inert, and direct or indirect firing systems. An inert system designed for indirect firing is the most common solution for cement plants. Equipped with the high-efficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the required

SAM GUARD • SAMSON SAMSON GROUP

Cement plant: raw mill separator Broken tooth of dynamic separator in raw mill. SAM GUARD gave pinpointed alerts, directing maintenance staff to the exact separator. The overlooked defective tooth could be replaced. A significant damage to the dynamic separator of the raw mill was prevented. ? Go to case study

05 Separating PDF Mechanical Fan Mill (Grinding)

Tikaria_Mill Workshop. SEPT-07 Dynamic Separators of 2nd Generation (Wedag) to filter Air flow direction. fresh air. 42. HGRS. Tikaria_Mill Workshop. SEPT-07 Dynamic Separators of 2nd Generation Basic function: Material enters the separator at the top. Air stream is generated by the external fan and. is recirculated. Coarse material is

Function Of Separator In Vertical Roller Mill

separator in vertical raw mill crusher distributor. Cement plant, what is the function of dynamic separator of raw mill. function of vertical roller mill liming heavy industry. Vertical roller mills are divided into vertical ore mill and vertical coal mill. Both the roller mills are used in for reGrinding under the function of

what is the function of dynamic separator of raw mill

mill (CM) is fed with raw materials. The milled product is fed via a recycle elevator to a dynamic separator. The high fineness stream of the separator constitutes the final circuit product, while the coarse material returns back to the CM to be ground again.

Cement Cyclone Separator In Cement Plant Factory Price

The material enters from the feed pipe and is scattered into the rising airflow through the dispersion plate. The pulverized medium debris in the material overcomes the falling resistance of the rising airflow under the action of gravity and is discharged through the slag discharge outlet.

Ball Mill an overview ScienceDirect Topics

To minimise over-grinding modern ball mills are fitted with dynamic separators (otherwise described as ‘classifiers’ or more simply as ‘separators’). as in raw mills, is integral with the mill body. In the Loesche mill, Fig. 2.23, 16 two pairs of rollers are used. In each pair the first, smaller diameter, roller stabilises the bed

sbm/sbm grinding system with static and dynamic separators.md

Contribute to changjiangsx/sbm development by creating an account on GitHub.

GRINDING AND SEPARATING TECHNOLOGY SYSTEMS

5 VERTICAL ROLLER MILL KTM Main data Type Min. motor power Max. motor power Min. capacity Max. capacity [kW] [kW] [t/h] [t/h] KTM 400 11 18,5 0,1 0,8 KTM 800 37 55 2 5 KTM 1000 55 90 4 8 KTM 1200 90 132 6 12 KTM 1400 132 200 9 18 KTM 1600 200 315 12 24 KTM 1800 315 400 20 38 KTM 2000 400 500 29 50 KTM 2200 500 630 39 64 KTM 2400

USA Dynamic separator for a grinding mill Google

A dynamic separator for a grinding mill having a stator installed in a stationary manner and a rotor provided on a rotary shaft such that it faces the stator. Between the stator and the rotor is provided a small gap for the passage of processed material in order to separate and discharge the processed material from the dispersion media.

Atox Raw Mill PDF Mill (Grinding) Bearing

Therefore the ATOX raw mill is equipped with the most updated version of the dynamic separator, which features: Cutsize and fineness adjusted by change in rotor speed Low bypass to reject ensures high separation

SAM GUARD • SAMSON USA

Cement plant: raw mill separator Broken tooth of dynamic separator in raw mill. SAM GUARD gave pinpointed alerts, directing maintenance staff to the exact separator. The overlooked defective tooth could be replaced. A significant damage to the dynamic separator of the raw mill was prevented. ? Go to case study

Dynamic Separator Karthi PDF Mill (Grinding) Force Scribd

PRINCIPLE OF DYNAMIC. SEPERATOR. SEPARTOR PRICIPLE: Separator has the key role to separating the mill product into two fractions, one containing finished products of desired fineness and the containing coarser material recycled to the mill for further grinding to achieve the fineness. Different elements of the separation process are

Separators in the cement industry

This separator is from KHD Humboldt Wedag AG. The V-separator is generally used with a pregrinding system (Roller Press). Applications mainly for raw meals, clinker and slag. The main objective of this

SAM GUARD • SAMSON SAMSON GROUP

The most important features and functions at a glance Coverage of the entire plant With SAM GUARD, you can keep track of the entire plant. SAM GUARD detects failures in rotating and static equipment as well as deviations in operating modes and process behavior. It's in your hands

sbm/sbm grinding system with static and dynamic separators.md

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Function Of Separator In Vertical Roller Mill

separator in vertical raw mill crusher distributor. Cement plant, what is the function of dynamic separator of raw mill. function of vertical roller mill liming heavy industry. Vertical roller mills are divided into vertical ore mill and vertical coal mill. Both the roller mills are used in for reGrinding under the function of

what is the function of dynamic separator of raw mill

mill (CM) is fed with raw materials. The milled product is fed via a recycle elevator to a dynamic separator. The high fineness stream of the separator constitutes the final circuit product, while the coarse material returns back to the CM to be ground again.

GRINDING AND SEPARATING TECHNOLOGY SYSTEMS

5 VERTICAL ROLLER MILL KTM Main data Type Min. motor power Max. motor power Min. capacity Max. capacity [kW] [kW] [t/h] [t/h] KTM 400 11 18,5 0,1 0,8 KTM 800 37 55 2 5 KTM 1000 55 90 4 8 KTM 1200 90 132 6 12 KTM 1400 132 200 9 18 KTM 1600 200 315 12 24 KTM 1800 315 400 20 38 KTM 2000 400 500 29 50 KTM 2200 500 630 39 64 KTM 2400

sbm/sbm function of separator in vertical roller mill.md at main

Contribute to dihog/sbm development by creating an account on GitHub.

crusher/sbm in cement mill seperator function and principle.md

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日The separator controls the product sizes from 400 to 40 μm. The moisture of the mill feed (cement raw material) can amount to 15–18 %. The fineness of the mill product can be adjusted in the range between 94 and 70 % passing 170 mesh. Capacities up to 400 t/h of cement raw mix are recorded [ 8 ]. 2.3.1.1. Cement quality

The SizingSelection of Hydrocyclones

vortex finder. The primary function of the vortex finder is to control both the separation and the flow leaving the cyclone. Also, the vortex finder is sufficiently extended below the feed entrance to prevent short circuiting of material directly into the overflow. The size of the vortex finder equals 0.35 times the cyclone diameter.