How To Use Impact Crushers

Impact Crusher an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness. Effect of process conditions on the production capacity of crushed materials is listed in

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As

How to use the impact crusher

2023年1月9日To use an impact crusher, you will need to select the appropriate size and model for your specific needs. Some general steps for operating an impact crusher are:

Impact Crusher Working Principle Mineral Processing

2015年6月22日Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by

Why use an impact crusher instead of other crushers?

2023年3月6日Impact crushers use the force of impact to crush material into a consistent and uniform size, making it easier for downstream processing. Impact crushers from

Tips to maximize crushing efficiency PitQuarry

2019年5月13日If closing the circuit at 1 in. to produce a 1-in.-minus product, set the crusher at or near 1 in. or slightly below. Feeding impact crushers Size reduction in

Impact Crusher Blow Bars The Ultimate Guide RUBBLE MASTER

RUBBLE MASTER impact crushers feature a single apron with 3 crushing stages that require only one setting to be set correctly. Rotor speed: the faster the rotor spins the

Choosing a mobile impact crusher for recycling what

2021年3月12日The impact crusher is a first- and second-stage crusher in one unit, so you can crush a 600-mm product down to a final product for resale as recycling aggregate.

ImpactCement Crusher Manufacturer Stedman

Stedman Machine has extensive experience crushing a variety of materials, a testing facility with full-sized equipment, and more than 10,000 test reports to help you

Home made Impact mill rock crusher for gold ore.

2015年4月27日This video examines the makeup and use of my home made impact mill rock crusher for liberating gold from gold ore. I explain hoe to make a rock crusher or a...

How does an impact crusher work? RUBBLE MASTER

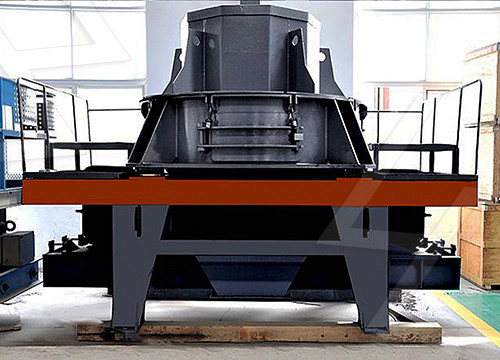

Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall. The striking and impacting causes the material to shatter into smaller pieces.

Crushing McLanahan

Impact crushing reduces material by utilizing the theory of mass versus velocity in two ways. In one method, material can be broken by its collision with hammers that are fixed to a spinning rotor. The material is broken

Choosing a mobile impact crusher for recycling what you

2021年3月12日The impact crusher is a first- and second-stage crusher in one unit, so you can crush a 600-mm product down to a final product for resale as recycling aggregate.

Finlay I 120RS impact crusher (concrete recycling)

2019年2月22日A key component of the machine is the on-board innovative quick detach 3.66m x 1.53m (12’ x 5’) two deck screen. For applications not requiring recirculation of materials for further

Impact Crusher Blow Bars The Ultimate Guide RUBBLE MASTER

RUBBLE MASTER impact crushers feature a single apron with 3 crushing stages that require only one setting to be set correctly. Rotor speed: the faster the rotor spins the more the material is hit. Operational factors The way how you run your impact crusher affects your wear life greatly.

ImpactCement Crusher Manufacturer Stedman Machine

An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized. Types of Impact Crushers: Horizontal shaft impactors (HSI) Cage mill pulverizers

How to crush aggregates?

2023年3月7日Choose the appropriate equipment for the job. Crushing equipment can range from small hand-held devices to large industrial machines. Some common types of equipment used for crushing aggregates...

Primary Impact Crushers Primary Impact Crushing Equipment

Mega Slam Horizontal Impactor Features. Reduction ratios up to 20:1. 360° Bearing contact = long bearing life. Features 2” thick housing liners. Solid Rotor with 3 or 4 breaker bar rows. Manual or power assist apron adjustment. Max-Yield™ automatic apron adjustment system. Reversible manganese monoblock aprons. Interchangeable side liners.

Vertical Shaft Impact Crusher AF Minerals Equipment

The output screen analysis of vertical impact crushers varies according to different parameters, the feed-screen analysis, the feed material, and the rotor speed. Material that is crushed using impact has a much more

Home made Impact mill rock crusher for gold ore. YouTube

2015年4月27日This video examines the makeup and use of my home made impact mill rock crusher for liberating gold from gold ore. I explain hoe to make a rock crusher or a...

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日The material enters the crusher and shatters upon impact with swinging hammers that are secured to a spinning rotor. The particles rebound off the breaker plates into the hammer circle and are carried into

Rotor centrifugal crusher Selective crusher with a vertical...

The input material is supplied to the center of the rotor centrifugal crusher from above. Once in the rotor, the material enters the two large centrifugal chambers, which ensure blockage-free operation and high throughput rates. The input material is propelled outwards with great force. This is followed by targeted impact against the fixed

Stationary VSI impact crushers, VSI Crusher Brochure

The results from using our VSI impact crushers speak for themselves, with 26% fewer wear parts compared to other leading VSI crushers, and up to 50% lower cost per ton when retrofitting Metso/Barmac VSI crushers. The perfect shape of aggregate to your requirements can be achieved due to our unique rotor and Bi-Flow design within

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Gyratory Crushers Jaw Crushers Impact Crushers; Typical rules for primary crusher selection: Rule 1: Always use a jaw crusher if you can due to lower costs. Rule 2: For low capacity applications, use jaw crusher and hydraulic hammer for oversize. Rule 3: For high capacities, use jaw crusher with big intake openings.

How does an impact crusher work? RUBBLE MASTER

Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall. The striking and impacting causes the material to shatter into smaller pieces.

Finlay I 120RS impact crusher (concrete recycling)

2019年2月22日A key component of the machine is the on-board innovative quick detach 3.66m x 1.53m (12’ x 5’) two deck screen. For applications not requiring recirculation of materials for further

Impact Crushers Primary McLanahan

Material enters an Impact Crushers' crushing chamber along a controlled feed angle. A spinning rotor assembly strikes the stone with a predetermined force sufficient to cause fragmentation. The trajectory of the material is then controlled to divert the flow back into the rotor circle, where the hammers (blowbars) continue to impact the material.

Impact Crusher Blow Bars The Ultimate Guide RUBBLE MASTER

RUBBLE MASTER impact crushers feature a single apron with 3 crushing stages that require only one setting to be set correctly. Rotor speed: the faster the rotor spins the more the material is hit. Operational factors The way how you run your impact crusher affects your wear life greatly.

Five Basic Safety Rules To Follow When Using An

2020年1月27日Below are five basic safety rules to follow when using an impact crusher to help keep accidents or injuries from occurring. 1. The only people who should work with or near the crusher are people who

Primary Impact Crushers Primary Impact Crushing Equipment

Mega Slam Horizontal Impactor Features. Reduction ratios up to 20:1. 360° Bearing contact = long bearing life. Features 2” thick housing liners. Solid Rotor with 3 or 4 breaker bar rows. Manual or power assist apron adjustment. Max-Yield™ automatic apron adjustment system. Reversible manganese monoblock aprons. Interchangeable side liners.

Vertical Shaft Impact Crusher AF Minerals Equipment

The output screen analysis of vertical impact crushers varies according to different parameters, the feed-screen analysis, the feed material, and the rotor speed. Material that is crushed using impact has a much more

Home made Impact mill rock crusher for gold ore. YouTube

2015年4月27日This video examines the makeup and use of my home made impact mill rock crusher for liberating gold from gold ore. I explain hoe to make a rock crusher or a...

Rock Crusher Eastman Rock Crusher

An impact crusher uses mass and velocity to break down feed material. First, the feed material is reduced as it enters the crusher with the rotating blow bars or hammers in the rotor. The secondary breakage occurs as

How to crush basalt rock?

2023年3月9日To crush basalt rock, you will need to use a secondary impact crusher or a cone crusher. This will make the rock smaller and more suitable for construction or landscaping uses. basalt rock crusher

Rotor centrifugal crusher Selective crusher with a

The input material is supplied to the center of the rotor centrifugal crusher from above. Once in the rotor, the material enters the two large centrifugal chambers, which ensure blockage-free operation and high throughput

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

Gyratory Crushers Jaw Crushers Impact Crushers; Typical rules for primary crusher selection: Rule 1: Always use a jaw crusher if you can due to lower costs. Rule 2: For low capacity applications, use jaw crusher and hydraulic hammer for oversize. Rule 3: For high capacities, use jaw crusher with big intake openings.

Stationary VSI impact crushers, VSI Crusher Brochure

Vertical shaft impact crushers accelerate the material to be crushed through a high energy rotor. This patented design moves the material into a crushing chamber and gives the “rock on rock” (autogenous) crushing action.

Impact Crushers and Screeners for Recycled Asphalt Kemper

Impact crushers are crucial in RAP production, and choosing the correct one for your needs is just as essential. There are two kinds of crushers you may use for your particular application. Mobile Impact Crushers If you require on-site recycling or have a smaller recycling operation, a mobile impact crusher might be the best tool for your