Latest Production Of Sand Machine For Aluminum

Advances in Core Making Technology Foundry

LKBinder, GMBOND, and ECOLOTEC, are examples of recent innovations. LKBinder is intended primarily for aluminum castings. It is reported to be free of odor, dimensionally

进一步探索

Cold Box Casting Process IndustrialmetalcastingsA STUDY OF CORE AND ITS TYPES FOR CASTING PRO根据热度为您推荐•反馈

Aluminum Association Releases 2021 Edition of Standards

2021年1月28日The latest Aluminum Association Molten Metal Incident Report found reported injuries at their lowest level since the report’s inception in the 1980s. the

进一步探索

Aluminum Standards and Data The Aluminum AssociationAluminum Design Manual 2020 The Aluminum Association根据热度为您推荐•反馈

Sand Aluminum Casting Market to Grow ly by

2023年2月23日The global major manufacturers of Sand Aluminum Casting include Alcoa, Dynacast International, Gibbs Die Casting, Ryobi, Martinrea Honsel, United

Aluminum Sand Casting Market 2023 LATEST [ R and D ]

2023年2月24日The USA market for Aluminum Sand Casting is estimated to increase from USD million in 2022 to reach USD million by 2028, at a CAGR of Percent during the

Military Aluminum Sand Castings Aerospace Castings Defense

Danko Arlington is an AS9100D, ISO 9001:2015 Registered, ITARHUBZone Certified full-service jobbing manufacturing company which specializes in military and commercial

3D sand printing for casting moldscores Voxeljet

With a 2,000-liter job box, it is one of the world's most productive 3D printing systems for sand casting. It is compatible with many sands and all furan and phenolic resin binders from voxeljet. Learn More. VX4000. The VX4000

Automated Sandblasting System and Equipment IST

AUTOMATED SANDBLASTING SYSTEMS. Ideal for integrated cell manufacturing and large-volume applications, ISTblast automated sandblasting systems integrate perfectly

Machined Aluminum vs Cast Aluminum, What’s the Difference

2022年2月22日The machined aluminum adopts the shape of the equal cross-section with little change, such as the heat sink of bulb lamp and the aluminum profile of doors and

Amazing Automatic Melting Aluminum Manufacturing

2018年11月29日About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features NFL Sunday Ticket Press Copyright

Aluminum Production and Processing The Aluminum Association

The latest Aluminum Association Molten Metal Incident Report found reported injuries at their lowest level since the report’s inception in the 1980s. Secondary production makes new aluminum from recycled scrap that for many products, like cans, is completely suitable for the same high quality. Sand, permanent mold and die casting

Aluminum Sand Casting Market 2023 LATEST [ R and D ]

2023年2月24日10 Production and Supply Forecast 11.1 Global Forecasted Production of Aluminum Sand Casting by Region (2023-2028) 11.2 North America Aluminum Sand Casting Production, Revenue Forecast (2023-2028

Military Aluminum Sand Castings Aerospace Castings Defense

Danko Arlington is an AS9100D, ISO 9001:2015 Registered, ITARHUBZone Certified full-service jobbing manufacturing company which specializes in military and commercial aluminum and bronze sand castings, 3-D sand, and 3-D plastic printing of rapid prototypes and production parts.

EMI Low Pressure Molding Machines

Dual cope ejection system for two cavity molds. Up to 20 channels of cooling water/air. Loose piece capabilities. 6 heavy duty side pulls for drag mold. Manual tool locks for ease of tooling loading. Tooling size up to 55″ x 64″

What is Sand Casting Process Application JC casting

2021年7月2日Sand casting, known as sand molding casting, is a casting process that uses sand as a mold. Then pour the liquid metal into this mold to create a casting part.It is one of the oldest casting processes. It can be

Metal Casting--Industry of the Future NREL

elements on the properties of aluminum die casting alloys is enabling die casters to reduce the weight of automotive castings by as much as 7%. Worcester Polytechnic Institute and over 20 industry partners •Saves energy in melting (est. 1.9 TBtu/yr in 2020) •Creates new markets for cast aluminum components Aluminum Alloy Microstructure

Sand Casting For Manufacture

Usually sand used to manufacture a mold for the casting process is held together by a mixture of water and clay. A typical mixture by volume could be 89% sand, 4% water, 7% clay. Control of all aspects of the properties of sand is crucial when manufacturing parts by sand casting, therefore a sand laboratory is usually attached to the foundry.

OEM Non-Standrd Great Mold Service Sand Investment Casting

Casting Method: Sand/Die/Investment Casting/ Casting Form Material: as Required Casting Metal: Iron/Steel/Aluminum/Alloy Steel/Stainless Steel Casting Form Usage Count: Permanent Surface Treatment: Powder Coating,Painting, Sand Blast Surface Roughness: Ra0.05-Ra12.5

mill/sbm grinding machine for aluminim sulphate.md at master

Machine Coolant Water Quality Carbide Processors The quality and pH levels of water can have a great effect on the Machine.Other ions contributing to hardness include iron,zinc,aluminum,potassium and silicon.and semi synthetics and soluble oils in both machining and grinding applications.Sulfate ions (SO4 2) can also contribute to corrosion

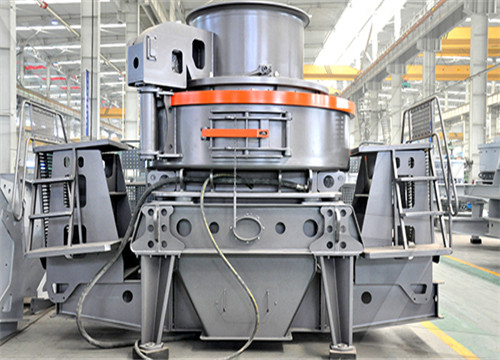

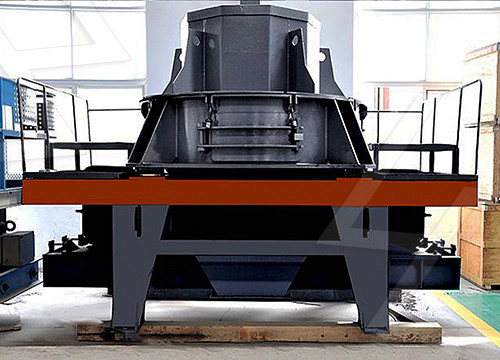

Sand casting equipment production line, cast iron

Sand casting equipment production line, cast iron cast aluminum molding machine 2,128 views May 9, 2019 Sand casting equipment production line, cast iron cast aluminum molding machine,...

Hot Delynn Sand Casting Quanzhou, China Core Shooting Small

Machine Features 1. The heat box core shooting machine is a kind of core shooting machine. It is a semi-automatic, vertical parting machine. 2. Simple, low cost, suitable for small quantity production. 3. The core shooting machine consists of three parts, such as mechanical part, pneumatic part and electrical part. 4.

Aluminium Gravity Die Casting Harrison Castings Ltd

Gravity Die Casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Undercuts, and cavities can be incorporated into the component form with the use of sand cores.

Sand Blasting Machine for Sale Mobile Portable Sandblaster Price

Features of Sand Blasting Machine for Sale in YG Machinery Simple operation. Ordinary workers can operate the machine after half an hour’s training, and an advanced automatic control system can prevent workers from operating by mistake. High production efficiency.

Aluminum Production and Processing The Aluminum Association

The latest Aluminum Association Molten Metal Incident Report found reported injuries at their lowest level since the report’s inception in the 1980s. Secondary production makes new aluminum from recycled scrap that for many products, like cans, is completely suitable for the same high quality. Sand, permanent mold and die casting

Aluminum Sand Casting Market 2023 LATEST [ R and D ]

2023年2月24日10 Production and Supply Forecast 11.1 Global Forecasted Production of Aluminum Sand Casting by Region (2023-2028) 11.2 North America Aluminum Sand Casting Production, Revenue Forecast (2023-2028

Military Aluminum Sand Castings Aerospace Castings Defense

Danko Arlington is an AS9100D, ISO 9001:2015 Registered, ITARHUBZone Certified full-service jobbing manufacturing company which specializes in military and commercial aluminum and bronze sand castings, 3-D sand, and 3-D plastic printing of rapid prototypes and production parts.

Handbook of Aluminum: Volume 2: Alloy Production and

2003年4月25日This reference provides thorough and in-depth coverage of the latest production and processing technologies encountered in the aluminum alloy industry, discussing current analytical methods...

Aluminium Gravity Die Casting Harrison Castings Ltd

Aluminium Gravity Die Casting at Harrison Castings Gravity die casting allows us to create high quality parts and components to even the most exacting of customer specifications. At Harrison Castings we produce

What is Sand Casting Process Application JC casting

2021年7月2日Sand casting, known as sand molding casting, is a casting process that uses sand as a mold. Then pour the liquid metal into this mold to create a casting part.It is one of the oldest casting processes. It can be

EMI Low Pressure Molding Machines

Dual cope ejection system for two cavity molds. Up to 20 channels of cooling water/air. Loose piece capabilities. 6 heavy duty side pulls for drag mold. Manual tool locks for ease of tooling loading. Tooling size up to 55″ x 64″

Metal Casting--Industry of the Future NREL

elements on the properties of aluminum die casting alloys is enabling die casters to reduce the weight of automotive castings by as much as 7%. Worcester Polytechnic Institute and over 20 industry partners •Saves energy in melting (est. 1.9 TBtu/yr in 2020) •Creates new markets for cast aluminum components Aluminum Alloy Microstructure

mill/sbm grinding machine for aluminim sulphate.md at master

Machine Coolant Water Quality Carbide Processors The quality and pH levels of water can have a great effect on the Machine.Other ions contributing to hardness include iron,zinc,aluminum,potassium and silicon.and semi synthetics and soluble oils in both machining and grinding applications.Sulfate ions (SO4 2) can also contribute to corrosion

Sand Casting For Manufacture

In fact, sand casting is one of the few processes that can be used for metals with high melting temperatures such as steels, nickel, and titanium. Usually sand used to manufacture a mold for the casting process is held together by a mixture of water and clay. A typical mixture by volume could be 89% sand, 4% water, 7% clay.

DSA AR15 Enhanced Low Mass Aluminum Sand Cut Complete

2023年3月4日We machine these assemblies using the latest manufacturing techniques, material and finishes. The carrier is machined from 7075 T-6 Aluminum and the bolt is MPI 9310 material. This complete AR15 M16 Cut Complete Low Mass Aluminum Sand Cut Enhanced Bolt Carrier Group includes the complete bolt, complete carrier with properly

Fantastic Casting Aluminum Using Sand Mold Process. Amazing

Fantastic Casting Aluminum Using Sand Mold Process. Amazing Metal Casting Technology Factory Machine.🔥🔥 Subscribe StarTech TV: https://youtube/Star...

Sand Blasting Machine for Sale Mobile Portable Sandblaster Price

Features of Sand Blasting Machine for Sale in YG Machinery Simple operation. Ordinary workers can operate the machine after half an hour’s training, and an advanced automatic control system can prevent workers from operating by mistake. High production efficiency.