Dewatering Centrifuge Main Parts

Centrifuges for dewateringseparation

Optimised dewatering and material separation will cut both your operating and cap-ex costs, as you reduce your environmental impact. Our advanced designs and experienced, qualified experts will ensure you receive the ideal equipment for your application, and the

Aldec sludge thickening and dewatering Alfa Laval

Complete, fully enclosed cleaning-in-place (CIP) The extensive range of ALDEC centrifuges for sludge thickening and dewatering are capable of handling a wide range of flow rates. They are designed to be efficient,

A Comprehensive Guide to Decanter Centrifuge

根据热度为您推荐•反馈

5Operation EN Alfa Laval

The main components of a decanter centrifuge are the bowl [5], the conveyor, the gearbox [3], the frame with the casing [6], and the feed and the discharge arrangement. The bowl

Decanter centrifuge Wikipedia

OverviewOperating principleParameters and influencing factors of the separationAdvantages and limitations over competitive processesDesigns availableDecanter centrifuges process characteristicsDesign heuristicsPost-treatment systems

A centrifuge is a device that employs a high rotational speed to separate components of different densities. This becomes relevant in the majority of industrial jobs where solids, liquids and gases are merged into a single mixture and the separation of these different phases is necessary. A decanter centrifuge (also known as solid bowl centrifuge) separates continuously solid materials from liquids in the slurry, and therefore plays an important role in the wastewater treatment, che

Decanter Centrifuge Elgin Separation Solutions

With over 550 centrifuges installed worldwide, Elgin’s centrifuges are a field proven solution. A decanter centrifuge is a mechanical device used for the separation of solids from slurries in many industrial processes. In oil

Centrifuge Parts Decanter Centrifuge Centrisys

Standard OEM centrifuge parts, ancillary equipment, and other technical items stocked to minimize centrifuge downtime including the following centrifuge parts: Kluber grease

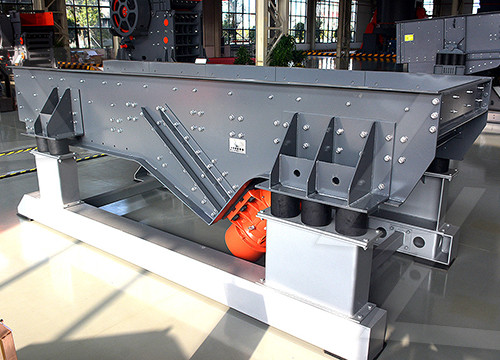

Dewatering Decanter Centrifuge (T Series) GN Separation

The main parts are made by centrifugal casting and die forging process to avoid intergranular corrosion and incomplete residual stress release caused by traditional welding process. The screw blade is pressed by the CNC

Dewateringprocessing tailings with centrifuges

Flottweg decanter centrifuges for dewatering tailings are manufactured only in Germany. Thus we can ensure the optimal quality of our machines. The quality of the materials

Title: Centrifuge Optimization

11 Centrifuge Seminar Decanter Centrifuges for Sludge Dewatering • The correct polymer can make the most dramatic difference in centrifuge performance. • Small scale jar

Aldec sludge thickening and dewatering Alfa Laval

Complete, fully enclosed cleaning-in-place (CIP) The extensive range of ALDEC centrifuges for sludge thickening and dewatering are capable of handling a wide range of flow rates. They are designed to be efficient,

Centrifuges for dewateringseparation

Optimised dewatering and material separation will cut both your operating and cap-ex costs, as you reduce your environmental impact. Our advanced designs and experienced, qualified experts will ensure you receive the ideal equipment for your application, and the support you need for your operation. Stay updated on your industry

Dewateringprocessing tailings with centrifuges Flottweg

Flottweg decanter centrifuges for dewatering tailings are manufactured only in Germany. Thus we can ensure the optimal quality of our machines. The quality of the materials used in mining and quarrying plays an important role. Materials which come into contact with the sludge are attacked by the sludge's abrasive components.

Centrisys Equipment: Systems: Skid, Trailer

Complete skid mounted dewatering systems are designed with all the components required for sludge dewatering and thickening in one single package with flow rates ranging from 0 to 1,200 gpm (0 272 m3/h).

Alfa Laval Preventive Maintenance

Always clean parts thoroughly before assembly. Tighten screws to the correct torque levels. 9. Use only genuine OEM-supplied tools for service and maintenance and store the tools in a clean, dry location. 10. Use only genuine spare parts for guaranteed performance, reliability and equipment life. Maintain a stock of key spare parts like grease

Decanter Centrifuge GN Separation Equipment Manufacturer

In the selection of raw materials for decanter centrifuges, high-quality centrifugal casting or forging stainless steel materials are used, and for wearing parts, hard alloy protection is used. GN high-end CNC lathes, CNC centers, and CNC gantry milling machines can better ensure the machining accuracy of centrifuge parts.

DEWATERING CENTRIFUGE REPAIR SERVICES QUESTIONS

4. Question: What is the time allowed for reassembly of the spare Humboldt S-4 centrifuge rotating assembly parts? Answer: As per scope description in Schedule A, part 1.1.A-General, the maximum time allowed for a major repair is 35 calendar days including transit time (plus any days required for District review/approval of recommended work). 5.

GNLW554-VFD decanter centrifuge for overseas glucose syrup

2023年3月9日This set of decanter centrifuge will be used for the clarification project of glucose syrup for overseas customer. Decanter centrifuge is commonly used solid-liquid separation equipment, through the high-speed rotating parts; the suspension passing into is separated into solid and liquid. The suspension to be treated needs to meet the density

Solid Bowl Scroll Centrifuge Horizontal Sludge Dewatering

Solid Bowl Scroll Centrifuge Horizontal Sludge Dewatering Decanter Centrifuge,Find Complete Details about Solid Bowl Scroll Centrifuge Horizontal Sludge Dewatering Decanter Centrifuge,Solid Bowl Centrifuge,Sludge Decanter Centrifuge,Sludge Centrifuge from Supplier or Manufacturer-Jinhua Shenzhou Centrifuge Co., Ltd.

Sludge treatment − centrifugal thickening Sludge Processing

2020年6月18日Dewatering centrifuges demand a higher energy consumption per unit dry solids mass (kg DS) to achieve the higher product solids concentrations. The dewatered product cannot then be pumped and can only be conveyed by a conveyor belt, whereas a thickened product retains the fluid properties of the feed and can therefore be pumped.

Comparison of Options for Biosolids Dewatering

Biosolids Dewatering Water Environment School 2017 Clackamas Community College •Math of Dewatering •Process Effects on Dewatering •Key Plant Criteria •Technology Overview: BFP, Screw, and Centrifuge –Process –Operation Parameters –Critical and Routine Maintenance •Major Considerations –Walkway around unit should allow

033-20 APPENDIX A TECHNICAL SPECIFICATIONS SKID

SKID- MOUNTED CENTRIFUGE DEWATERING SYSTEM . PART 1 GENERAL . 1.01 DESCRIPTION . A. Scope: 1. One new or refurbished skid-mounted centrifuge sludge dewatering system, capable of being Free-standing control panel with PLC based controls for interfacing with main treatment plant operation and SCADA system 2.

Mechanical Dewatering SSWM Find tools for

Dewatering can be done either with the help of presses or centrifuges (mechanical dewatering), filtration (e.g. in filter bags) or physical (and biological) processes in drying beds. Mechanical dewatering and

Industry Decanter Centrifuge GN Solids Control

three-phase centrifuges are significantly improved by the control system. Main Function of GN Industry Centrifuges Dewatering sludge / mud and suspensions Thickening sludge or mud Clarifying different type liquids Separating 3-phase mixtures, i.e. two immiscible fluid phases and a solid phase

Aldec sludge thickening and dewatering Alfa Laval

Complete, fully enclosed cleaning-in-place (CIP) The extensive range of ALDEC centrifuges for sludge thickening and dewatering are capable of handling a wide range of flow rates. They are designed to be efficient,

Centrifuges for dewateringseparation

Optimised dewatering and material separation will cut both your operating and cap-ex costs, as you reduce your environmental impact. Our advanced designs and experienced, qualified experts will ensure you receive the ideal equipment for your application, and the support you need for your operation. Stay updated on your industry

Dewateringprocessing tailings with centrifuges Flottweg

Flottweg decanter centrifuges for dewatering tailings are manufactured only in Germany. Thus we can ensure the optimal quality of our machines. The quality of the materials used in mining and quarrying plays an important role. Materials which come into contact with the sludge are attacked by the sludge's abrasive components.

Comparison of Options for Biosolids Dewatering

Biosolids Dewatering Water Environment School 2017 Clackamas Community College •Math of Dewatering •Process Effects on Dewatering •Key Plant Criteria •Technology Overview: BFP, Screw, and Centrifuge –Process –Operation Parameters –Critical and Routine Maintenance •Major Considerations –Walkway around unit should allow

Industry Decanter Centrifuge GN Solids Control

three-phase centrifuges are significantly improved by the control system. Main Function of GN Industry Centrifuges Dewatering sludge / mud and suspensions Thickening sludge or mud Clarifying different type liquids Separating 3-phase mixtures, i.e. two immiscible fluid phases and a solid phase

Alfa Laval Preventive Maintenance

Always clean parts thoroughly before assembly. Tighten screws to the correct torque levels. 9. Use only genuine OEM-supplied tools for service and maintenance and store the tools in a clean, dry location. 10. Use only genuine spare parts for guaranteed performance, reliability and equipment life. Maintain a stock of key spare parts like grease

DEWATERING CENTRIFUGE REPAIR SERVICES QUESTIONS

4. Question: What is the time allowed for reassembly of the spare Humboldt S-4 centrifuge rotating assembly parts? Answer: As per scope description in Schedule A, part 1.1.A-General, the maximum time allowed for a major repair is 35 calendar days including transit time (plus any days required for District review/approval of recommended work). 5.

GNLW554-VFD decanter centrifuge for overseas glucose syrup

2023年3月9日This set of decanter centrifuge will be used for the clarification project of glucose syrup for overseas customer. Decanter centrifuge is commonly used solid-liquid separation equipment, through the high-speed rotating parts; the suspension passing into is separated into solid and liquid. The suspension to be treated needs to meet the density

Solid Bowl Scroll Centrifuge Horizontal Sludge Dewatering

Solid Bowl Scroll Centrifuge Horizontal Sludge Dewatering Decanter Centrifuge,Find Complete Details about Solid Bowl Scroll Centrifuge Horizontal Sludge Dewatering Decanter Centrifuge,Solid Bowl Centrifuge,Sludge Decanter Centrifuge,Sludge Centrifuge from Supplier or Manufacturer-Jinhua Shenzhou Centrifuge Co., Ltd.

Sludge treatment − centrifugal thickening Sludge Processing

2020年6月18日Dewatering centrifuges demand a higher energy consumption per unit dry solids mass (kg DS) to achieve the higher product solids concentrations. The dewatered product cannot then be pumped and can only be conveyed by a conveyor belt, whereas a thickened product retains the fluid properties of the feed and can therefore be pumped.

Mechanical Dewatering SSWM Find tools for

Executive Summary. Mechanical dewatering is normally associated with large wastewater treatment plants and is used to separate sludge (residual sludge from wastewater treatment plants or faecal sludge from on-site

Wastewater Centrifuge Sludge DewateringThickening

A sludge dewatering or sludge thickening centrifuge is a decanter-type horizontal de-sludger that can remove water from slurries to thicken the sludge. In other words, a heavy-duty industrial centrifuge dewaters and concentrates (thickens) the sludge, also known as a sludge thickening machine. These machines are available in different sizes to

4 Innovative Ways Centrisys Supports Centrifuge Parts Replacement

The facility houses over $9M of standard OEM decanter centrifuge parts, ancillary equipment, and other technical items to minimize centrifuge downtime, including: Kluber grease centrifuge bearings (ball, thrust, needle, cylindrical roll) o-rings sensors cables valves feed nozzles gaskets feed pipes centrifuge filters

Liquid Stream Fundamentals: Grit Removal Water

Grit removal is part of the preliminary removal treatment process (See Screenings Removal Fact Sheet for more information on preliminary treatment). It is critical for the protection of dewatering centrifuges and high-pressure progressing cavity, rotary lobe, and diaphragm pumps, all of which are damaged by grit. For facilities with primary