2012 Newly High Intensity Wet Magnetic Separator

Wet High Intensity Magnetic Separators Multotec

Wet High Intensity Magnetic Separators (WHIMS) from Multotec combine magnetism, matrix rotation and gravity to para-magnetic materials. Applications include heavy

Intensity Magnetic Separator an overview

The Jones wet high-intensity magnetic separator (WHIMS) was developed in 1956.The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron

进一步探索

High Intensity Magnetic Separation FundamentalsA Guide to Magnetic Separation Eclipse Magnetics根据热度为您推荐•反馈

Wet High Intensity Magnetic Separator (HGMS / WHIMS) Magquip

The MAGQUIP Wet High Intensity Magnetic Separator (WHIMS) is a high gradient magnet used for the concentration of slurries containing weakly magnetic minerals. The

WET HIGH INTENSITY MAGNETIC SEPARATOR (WHIMS)

14 行Wide separation range: upper limit:6mm, lower limit :2~10μm; 17 series of

Technical Explanation of the Laboratory Wet High

2021年1月21日Professor Neil Rowson gives a technical presentation and demonstration of the laboratory-scale Wet High Intensity Magnetic Separator. This specialised magne...

Wet Magnetic Drum Separator Sepor, Inc

The most common type of wet drum separator is the low intensity wet drum separator, for recovering highly magnetic material. The drum has a magnetic field from 600 to 1,000 gauss, typically. Wet high intensity

Wet High Intensity Magnetic Separation

2017年6月4日Wet High-Intensity Magnetic Separation Results Tests were conducted on a bulk sample of oxidized taconite from the western Mesabi Range. The sample represents ½ to 1 billion tons of crude ore.

Wet Magnetic Drum Separator 911Metallurgist

Wet Magnetic Drum Separator Low-intensity separators are used to treat ferromagnetic materials and some highly paramagnetic minerals. Minerals with ferromagnetic properties have high susceptibility at low applied field

allgauss® Wet High Intensity Magnetic Separator

2019年5月21日Watch out our movie for the allgauss®allgauss® will be delivered to our project site in Spain.The allgauss® is a Wet High Intensity Magnetic Separator that o...

MMPB-481 Wet HigH intensity Magnetic separator

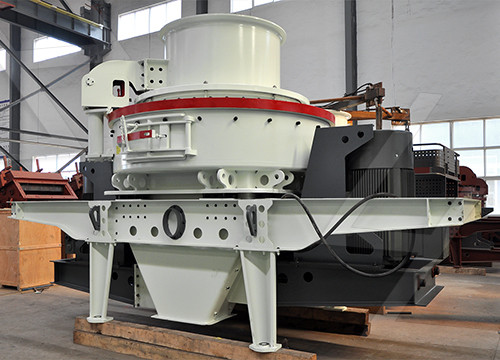

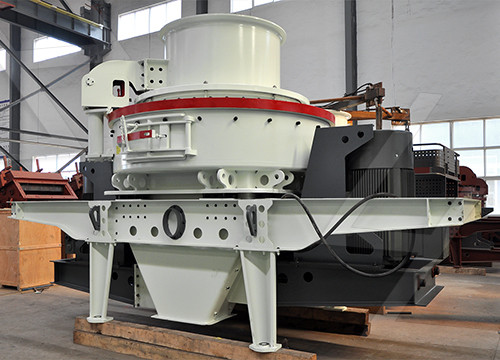

WET HIGH INTENSITY MAGNETIC SEPARATOR fiWHIMSfl. When a DC current is applied to the coil (1), a magnetic field is formed in the separating compartment (2). A high magnetic field gradient is generated in the vicinity of the . rod in matrix (2). The vertical rotating separation ring (3) is driven clockwise by the drive motor and reducer (4)

Intensity Magnetic Separator an overview ScienceDirect Topics

The Jones wet high-intensity magnetic separator (WHIMS) was developed in 1956.The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron-core electromagnet, a vertical shaft with two (or more) separating rings, a driving system, and feeding and product collection devices. Grooved plates made of magnetic conductive

Technical Explanation of the Laboratory Wet High Intensity Magnetic

2021年1月21日Professor Neil Rowson gives a technical presentation and demonstration of the laboratory-scale Wet High Intensity Magnetic Separator. This specialised magne...

WET HIGH INTENSITY MAGNETIC SEPARATOR (WHIMS)

Wide separation range: upper limit:6mm, lower limit :2~10μm; 17 series of products with more than 70 specifications and models, and capacity of a single unit is from 0.01 to 480t/h; Equipped with coil pipeline cleaning system, easy for coil daily maintenance. coil designed life is up to 10 years. Product Details How does it work?

Wet Magnetic Drum Separator Sepor, Inc

Wet high intensity magnetic separators are also used for para-magnetic materials, with magnetic field intensity ranging from 7,000 gauss (Permanent Drum) to 20,000 gauss (Electro-magnetic drums). We have

Wet High Intensity Magnetic Seperator (WHIMS)

Wet High Intensity Magnetic Separator. HMD are proud to introduce the “Next Generation’ in Wet Magnetic Separation equipment (WHIMS) an innovative new conceptual design that addresses many of the inherent

Magnetic Separators Wet High-Intensity Magnetic

High-Intensity Magnetic Separators for Industrial Applications. We helped them pull their old magnets offline and temporarily replaced them with something more suitable: A modern in-line, auto-purging, self-cleaning

Wet High Intensity Magnetic Separator

TungstenHigh-Intensity Wet Magnetic Separator Wolframite minerals, being weakly magnetic with a specific susceptibility of 39×10 -6 to 46×10 -6 cm³/g, can be effective separated from cassiterite and other nonmagnetic

Wet Magnetic Drum Separator 911Metallurgist

Wet Magnetic Drum Separator Low-intensity separators are used to treat ferromagnetic materials and some highly paramagnetic minerals. Minerals with ferromagnetic properties have high susceptibility at low applied field

Used wet high intensity magnetic separator Machinio

High Intensity Roller Magnetic Separator. NEW. Manufacturer: Huatao. Model: HT29. High Intensity Roller Magnetic Separator Product Description The High Intensity Roller Magnetic Separator is suitable for wet magnetic separation of magnetic materials such as magnetite, pyrrhotite, roasted ore, Hebei, China.

Working Principle Of SLon Wet High Intensity Magnetic Separator(WHIMS

Here is the working principle Of SLon Wet High Intensity Magnetic Separator(WHIMS). In the field of mineral processing industry, SLon is the creator of Verti...

Influence of matrix type on WHIMS performance in the magnetic

2020年6月15日The other magnetic separator used was a “Gill” 4-pole wet magnetic separator manufactured by Readings of Lismore, New South Wales, Australia. This is essentially a medium intensity wet magnetic separator with a maximum field strength of approximately 1.4 T ( Lawver and Hopstock, 1974 ).

Wet High Intensity Magnetic Separation of Iron Minerals

1996年1月1日Magnetic separation using wet high-intensity technique has become one of the most suitable methods for recovery of iron from low-grade ores [6], due to its better separation efficiency...

For dry and wet processing Low Intensity Magnetic

Magnetic separation process Magnetic separation technology can roughly be divided into three classes of magnetic intensity i.e., low, medium, and high, all depending on the characteristics of the minerals subjected to magnetic processing: • Strong magnetic minerals (ferromagnetic) can be processed by Low Intensity Magnetic Separators (LIMS).

Influence of matrix type on WHIMS performance in the magnetic

2020年6月15日The other magnetic separator used was a “Gill” 4-pole wet magnetic separator manufactured by Readings of Lismore, New South Wales, Australia. This is essentially a medium intensity wet magnetic separator with a maximum field strength of approximately 1.4 T ( Lawver and Hopstock, 1974 ).

MMPB-481 Wet HigH intensity Magnetic separator

WET HIGH INTENSITY MAGNETIC SEPARATOR fiWHIMSfl. When a DC current is applied to the coil (1), a magnetic field is formed in the separating compartment (2). A high magnetic field gradient is generated in the vicinity of the . rod in matrix (2). The vertical rotating separation ring (3) is driven clockwise by the drive motor and reducer (4)

Intensity Magnetic Separator an overview ScienceDirect Topics

The Jones wet high-intensity magnetic separator (WHIMS) was developed in 1956.The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron-core electromagnet, a vertical shaft with two (or more) separating rings, a driving system, and feeding and product collection devices. Grooved plates made of magnetic conductive

Technical Explanation of the Laboratory Wet High Intensity Magnetic

2021年1月21日Technical Explanation of the Laboratory Wet High Intensity Magnetic Separator 464 views Jan 21, 2021 Professor Neil Rowson gives a technical presentation and demonstration of the...

Magnetic Drum Separator (Wet) Sepor, Inc

The most common type of wet drum separator is the low intensity wet drum separator, for recovering highly magnetic material. The drum has a magnetic field from 600 to 1,000 gauss, typically. Wet high intensity

Wet High Intensity Magnetic Seperator (WHIMS)

Wet High Intensity Magnetic Separator. HMD are proud to introduce the “Next Generation’ in Wet Magnetic Separation equipment (WHIMS) an innovative new conceptual design that addresses many of the inherent

Magnetic Separators Wet High-Intensity Magnetic

High-Intensity Magnetic Separators for Industrial Applications. We helped them pull their old magnets offline and temporarily replaced them with something more suitable: A modern in-line, auto-purging, self-cleaning

Working Principle Of SLon Wet High Intensity Magnetic Separator(WHIMS

2020年10月20日Here is the working principle Of SLon Wet High Intensity Magnetic Separator(WHIMS). In the field of mineral processing industry, SLon is the creator of Verti...

High Gradient Magnetic Separator

2019年1月10日High-intensity wet magnetic separators have been successfully introduced into, the mineral processing field over the past ten to fifteen years, due largely to rapid advancements in magnet design. Wet

Used wet high intensity magnetic separator Machinio

NEW Manufacturer: Huatao Model: HT29 High Intensity Roller Magnetic Separator Product Description The High Intensity Roller Magnetic Separator is suitable for wet magnetic separation of magnetic materials such as magnetite, pyrrhotite, roasted ore, Hebei, China Click to Request Price Trusted Seller High Intensity Magnetic Separator

A discussion of magnetic separation techniques for SAIMM

• Dry high-intensity rare-earth drum (RED) separators, and • Dry high-intensity rare-earth roll (RER) separators Figure 1 depicts the basic magnetic separation technologies now available in the marketplace in terms of field intensities and modes of processing. LIMS and scalper magnets are not detailed in this . The selection of

For dry and wet processing Low Intensity Magnetic

Magnetic separation process Magnetic separation technology can roughly be divided into three classes of magnetic intensity i.e., low, medium, and high, all depending on the characteristics of the minerals subjected to magnetic processing: • Strong magnetic minerals (ferromagnetic) can be processed by Low Intensity Magnetic Separators (LIMS).

High-intensity magnetic separator Wikipedia

Magnetic separators that used permanent magnets could generate fields of low intensity only. These worked well in removing ferrous tramp but not fine paramagnetic particles. Thus high- intensity magnetic separators that were effective in collecting paramagnetic particles came into existence. These focus on the separation of very fine particles