Magnetic Separator For Nickel Ore

Development of Special Magnetic Separator to Recover

2022年6月16日The special magnetic separator JCTN0912 (Ø900 × 1200) mainly consists of separation cylinder, flush water device, feed tank, separation chamber,

Efficient enrichment of nickel and iron in laterite nickel

2020年3月1日Results show that nickel–iron concentrates with nickel grade of 6.96%, nickel recovery of 94.06%, iron grade of 34.74%, and iron recovery of 80.44% could be

Extraction of Nickel from Garnierite Laterite Ore Using

30%, a coke dosage of 15%, a coke size of 1 + 0.5 mm, a magnetic separation grinding fineness of <45 m occupying 90%, and a magnetic separation magnetic field

High Field Intensity Nickel Magnetic Beneficiation

2021年6月19日Nickel ore magnetic beneficitiation studies completed. studies have started for industrial scale nickel magnetic enrichment production with high field intensity permroll magnetic separators. As a

Study on selective reduction and magnetic separation of

2010年1月1日Li et al. (2010) investigated the effects of selective reduction and magnetic separation of nickel laterite ore containing 0.97% nickel to produce a high grade nickel concentrate. With...

magnetic separator BAS®

2021年5月15日Magnetic Separators are ready for shipment to Copper Beneficiation Plant Magnet separators, belt scales and detectors are ready for shipment to Copper

Upgrading low nickel content laterite ores using selective

2012年5月20日DOI: 10.1016/J.MINPRO.2012.01.003 Corpus ID: ; Upgrading low nickel content laterite ores using selective reduction followed by magnetic

Overband Permanent Magnetic Separator Nickel Ore Processing

Overband Magnetic Separator. Nickel Ore Processing Equipment; In Over band permanent magnetic separator, continuous cleaning is made possible by a heavy duty

Wet Drum Separator Nickel Ore Processing Star Trace Pvt. Ltd.

The magnetic flux pattern will match the tank configuration for optimum performance. Star Trace magnetic wet separator dia 916 x 300mm is the smallest full scale separator in

Efficient enrichment of nickel and iron in laterite nickel ore by

2020年3月1日Results show that nickel–iron concentrates with nickel grade of 6.96%, nickel recovery of 94.06%, iron grade of 34.74%, and iron recovery of 80.44% could be obtained after magnetic separation under the conditions of reduction temperature of 1275 °C, reduction time of 50 min, slag basicity of 1.0, carbon-containing coefficient of 2.5, and

High Field Intensity Nickel Magnetic Beneficiation

2021年6月19日Nickel ore magnetic beneficitiation studies completed. studies have started for industrial scale nickel magnetic enrichment production with high field intensity permroll magnetic separators. As a

Development of Special Magnetic Separator to Recover Precious

2022年6月1日Magnetic field simulation of the special magnetic separator indicates that magnetic intensity of 0.6 T can be generated on the surface of magnetic drum, which can strengthen the recovery...

Extraction of Nickel from Garnierite Laterite Ore Using

30%, a coke dosage of 15%, a coke size of 1 + 0.5 mm, a magnetic separation grinding fineness of <45 m occupying 90%, and a magnetic separation magnetic field intensity of H = 0.10 T. The main minerals in ferronickel concentrate are Fe, [Ni]Fe, Fe3O4, and a small amount of gangue minerals, such as CaOSiO2 and CaOAl2O3SiO2.

Extraction of Nickel from Garnierite Laterite Ore Using Roasting

2020年4月15日Abstract and Figures In this study, segregation roasting and magnetic separation are used to extract nickel from a garnierite laterite ore. The garnierite laterite ore containing 0.72%...

Upgrading low nickel content laterite ores using selective

2012年5月20日DOI: 10.1016/J.MINPRO.2012.01.003 Corpus ID: ; Upgrading low nickel content laterite ores using selective reduction followed by magnetic separation @article{Zhu2012UpgradingLN, title={Upgrading low nickel content laterite ores using selective reduction followed by magnetic separation}, author={De‐qing Zhu and Yu Cui

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

Nickel Ore Beneficiation Plant Nickel Ore Processing

Nickel Ore Processing Equipment. Star Trace Nickel Ore Processing uses the following equipments for the entire process: Hydrocyclone, Dewatering Screen, Magnetic Roll Separator, Belt Conveyor, Sand Washer, Screw Classifier, Spiral Separator, Concentrating Table, Dryer, Density Separator, HT Separator, Cooler.

Overband Permanent Magnetic Separator Nickel Ore

Overband Magnetic Separator. Nickel Ore Processing Equipment; In Over band permanent magnetic separator, continuous cleaning is made possible by a heavy duty clad belt that encircles the magnet on a series of rotating pulleys. As ferrous metal is attracted and held by the magnet, the moving belt carries the collected metal outside of the

ADVANCES IN MAGNETIC SEPARATION OF ORES

sten, molybdenum, nickel, niobium, and tantalum ores. Pioneer Work on Dry Separation: It is interesting to note that much of the pioneer work in magnetic dry magnetic separation to beneficiate iron ore. Wet concentration of magnetite ore, in comparison, re- quires 500 to 1000 gal of water per ton of concen-

Preparation of LiFePO4/C cathode material by extracting Fe2O3

2022年11月1日DOI: 10.1016/j.jallcom.2022.168078 Corpus ID: ; Preparation of LiFePO4/C cathode material by extracting Fe2O3 from laterite nickel ore by ammonium jarosite method @article{Chang2022PreparationOL, title={Preparation of LiFePO4/C cathode material by extracting Fe2O3 from laterite nickel ore by ammonium jarosite

Extraction of Nickel from Garnierite Laterite Ore Using Roasting

2020年4月15日In this study, segregation roasting and magnetic separation are used to extract nickel from a garnierite laterite ore. The garnierite laterite ore containing 0.72% Ni, 0.029% Co, 8.65% Fe, 29.66% MgO, and 37.86% SiO 2

NCERT Solutions for Class 12 Chemistry Chapter 6 General

Only those ores can be concentrated by magnetic separation method in which either the ore particles or the impurities associated with it are of magnetic nature. For example, ores of iron such haematite (Fe 2 O 3), magnetite (Fe 3 O 4), siderite (FeCO 3) are magnetic and can be concentrated by this method. Similarly, casseterite (SnO 2

Ore Magnetic Separation Machine Wholesale ec21

Wholesale Ore Magnetic Separation Machine ☆ Find 34 ore magnetic separation machine products from 13 manufacturerssuppliers at EC21. ☆ Choose quality ore magnetic separation machine manufacturers, suppliersexporters now EC21

High Field Intensity Nickel Magnetic Beneficiation

2021年6月19日Nickel ore magnetic beneficitiation studies completed. That summary started at Bas mineralogical labratory. After the positive results of laboratory-scale studies in low grade nickel ore magnetic

Development of Special Magnetic Separator to Recover Precious

2022年6月1日Magnetic field simulation of the special magnetic separator indicates that magnetic intensity of 0.6 T can be generated on the surface of magnetic drum, which can strengthen the recovery...

Extraction of Nickel from Garnierite Laterite Ore Using

30%, a coke dosage of 15%, a coke size of 1 + 0.5 mm, a magnetic separation grinding fineness of <45 m occupying 90%, and a magnetic separation magnetic field intensity of H = 0.10 T. The main minerals in ferronickel concentrate are Fe, [Ni]Fe, Fe3O4, and a small amount of gangue minerals, such as CaOSiO2 and CaOAl2O3SiO2.

Upgrading nickel content of limonite nickel ore through

2018年4月3日Limonite nickel ore has potency to utilize as raw material for ferronickel or nickel matte, since it has low grade nickel content, thus process development is needed to find the acceptable process

Upgrading low nickel content laterite ores using selective

2012年5月20日DOI: 10.1016/J.MINPRO.2012.01.003 Corpus ID: ; Upgrading low nickel content laterite ores using selective reduction followed by magnetic separation @article{Zhu2012UpgradingLN, title={Upgrading low nickel content laterite ores using selective reduction followed by magnetic separation}, author={De‐qing Zhu and Yu Cui

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

Nickel Ore Beneficiation Plant Nickel Ore Processing

Nickel Ore Processing Equipment Star Trace Nickel Ore Processing uses the following equipments for the entire process: Hydrocyclone, Dewatering Screen, Magnetic Roll Separator, Belt Conveyor, Sand Washer, Screw Classifier, Spiral Separator, Concentrating Table, Dryer, Density Separator, HT Separator, Cooler. Welcome to Star Trace Private

Overband Permanent Magnetic Separator Nickel Ore

Overband Magnetic Separator. Nickel Ore Processing Equipment; In Over band permanent magnetic separator, continuous cleaning is made possible by a heavy duty clad belt that encircles the magnet on a series of rotating pulleys. As ferrous metal is attracted and held by the magnet, the moving belt carries the collected metal outside of the

Preparation of LiFePO4/C cathode material by extracting Fe2O3

2022年11月1日DOI: 10.1016/j.jallcom.2022.168078 Corpus ID: ; Preparation of LiFePO4/C cathode material by extracting Fe2O3 from laterite nickel ore by ammonium jarosite method @article{Chang2022PreparationOL, title={Preparation of LiFePO4/C cathode material by extracting Fe2O3 from laterite nickel ore by ammonium jarosite

ADVANCES IN MAGNETIC SEPARATION OF ORES

sten, molybdenum, nickel, niobium, and tantalum ores. Pioneer Work on Dry Separation: It is interesting to note that much of the pioneer work in magnetic dry magnetic separation to beneficiate iron ore. Wet concentration of magnetite ore, in comparison, re- quires 500 to 1000 gal of water per ton of concen-

Extraction of Nickel from Garnierite Laterite Ore Using Roasting

2020年4月15日In this study, segregation roasting and magnetic separation are used to extract nickel from a garnierite laterite ore. The garnierite laterite ore containing 0.72% Ni, 0.029% Co, 8.65% Fe, 29.66% MgO, and 37.86% SiO 2

NCERT Solutions for Class 12 Chemistry Chapter 6 General

Only those ores can be concentrated by magnetic separation method in which either the ore particles or the impurities associated with it are of magnetic nature. For example, ores of iron such haematite (Fe 2 O 3), magnetite (Fe 3 O 4), siderite (FeCO 3) are magnetic and can be concentrated by this method. Similarly, casseterite (SnO 2

Ore Magnetic Separation Machine Wholesale ec21

Wholesale Ore Magnetic Separation Machine ☆ Find 34 ore magnetic separation machine products from 13 manufacturerssuppliers at EC21. ☆ Choose quality ore magnetic separation machine manufacturers, suppliersexporters now EC21

Separation and Recovery of Iron and Nickel from Low-Grade

2018年10月1日The low-grade nickel laterite ore used in this study was successfully upgraded through selective reduction by industrialized rotary kilns followed by magnetic separation. The results indicated that both iron metallization extent and nickel metallization extent showed obvious linear correlation.

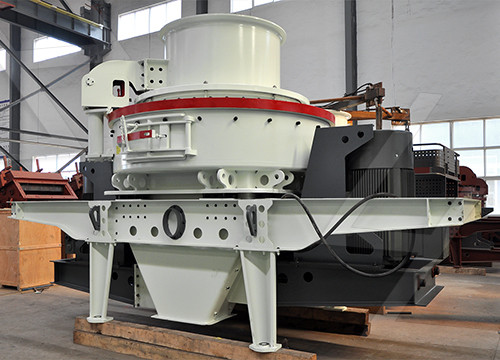

- Basalt Cone Crusher Spring Cone Crusher 50 90t H

- 冶金用反击碎石机

- 中国粉碎机

- 排气管生产需要哪些机械

- 江都破碎机厂

- 钛白粉磨粉机

- Cubicmeter Per Hour Grinding Mill

- Conveyor Belt In Visakhapatnam

- 流动碎石机大约多少钱

- Raymond Grinding Mill Rent In India

- 矿用破碎机流程图

- Automobile Stone Mining Mill India

- 重晶石生产线-矿石设备厂家价格

- Ce Mark Carbon Steel Durable Iron Ore Vibrating Screen

- Mill Kamgar Phoenix Lottery List