High Efficiency Specularite Iron Ore Magnetic Separator Wet Type

Effective Processing of Specularite Ore by Wet

The processing a specularite sample using wet magnetic separation and reverse flotation method was studied. During the magnetic separation process, particle size was -2000

Effective Processing of Specularite Ore by Wet Magnetic

2019年9月30日Iron ores can be classified into three types: quartztype, carbonate-type, and silicate-type, according to the associated gangue

Developments in the physical separation of iron ore:

2015年1月1日The Jones wet high-intensity magnetic separator (WHIMS) was developed in 1956. The structure of the Jones separator is shown in Figure 9.6 and consists mainly

Effective Processing of Specularite Ore by Wet Magnetic

T he aim of this study was to obtain a high grade and yield percentage of iron concentrate from a specularite ore by using wet magnetic separation and reverse flotation

Increasing efficiency of iron ore magnetic separation by using

enhance efficiency of iron ore magnetic separation by applying ultrasonic technologies. Thus, it is required to combine research results in the following directions: theoretical and

Wet Magnetic Drum Separator 911Metallurgist

Low-intensity separators are used to treat ferromagnetic materials and some highly paramagnetic minerals. Minerals with ferromagnetic properties have high susceptibility at low applied field strengths and can therefore

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)

14 行Product Description: SLon has finished the design of the largest SLon-5000 VPHGMS (WHIMS), whose single unit capacity can reach up to 950t/h. In the past 30

High Efficiency Wet Drum Type Magnetic Separator for

Wet drum permanent magnetic separator is suitable for mine, coal preparation plant etc. use weak wet magnetic field to sort out the strong magnetic ore, or e...

Magnetic Separation and Iron Ore Beneficiation IspatGuru

2018年10月4日The third type of magnetic wet drum separator, the counter-current drum, is often used as a finishing separator because it produces an extremely clean concentrate with good recovery for

Effective Processing of Specularite Ore by Wet Magnetic

DOI: 10.17350/hjse Corpus ID: ; Effective Processing of Specularite Ore by Wet Magnetic Separation and Reverse Flotation Techniques

Effective Processing of Specularite Ore by Wet Magnetic

During the magnetic separation process, particle size was -2000 µm and magnetic field applied at 0.25 T and 0.85 T which were performed at a solid-liquid ratio of 10% and 20% by weight, respectively.

Effective Processing of Specularite Ore by Wet

2019年9月30日On the other hand, because oxidized iron ores like martite, hematite, specularite, limonite, and siderite are weakly magnetic, high-intensity magnetic separators and high-gradient magnetic

Developments in the physical separation of iron ore: magnetic

2015年1月1日The Jones wet high-intensity magnetic separator (WHIMS) was developed in 1956. The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron-core electromagnet, a vertical shaft with two (or more) separating rings, a driving system, and feeding and product collection devices.

MMPB-470O Wet Drum Separators Eriez

Wet drum magnetic separators are the most vital part of the upgrading process in magnetite concentration. The upgrading of primary magnetite is always accomplished with wet drum separators. Mill feed is typically upgraded to 65+ percent magnetic iron using a series of wet drum magnetic separators. The number of magnetic separation

Effective Processing of Specularite Ore by Wet Magnetic Separation

T he aim of this study was to obtain a high grade and yield percentage of iron concentrate from a specularite ore by using wet magnetic separation and reverse flotation techniques. The processing a specularite sample using wet magnetic separation and reverse flotation method was studied. During the magnetic separation process, particle size was -2000

Magnetic Separators 911Metallurgist

High intensity magnetic separators that were effective in collecting fine paramagnetic particles utilized electromagnetic circuits. These separators were large, heavy, low capacity machines that typically consumed an

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)

Product Description: SLon has finished the design of the largest SLon-5000 VPHGMS (WHIMS), whose single unit capacity can reach up to 950t/h. In the past 30 years, SLon has focused on the innovation and promotion of mineral processing techonology, and completed the design, manufacture and utilization of over 70 models of VPHGMS.

Specularite Ore Beneficiation Studies BAS®

2022年6月30日In here specularite beneficiation studies that has been completed in the Eastern Aegean; high field intensity slon type electromagnetic separators are used. Work on obtaining the final product %65Fe with maximum product recovery with different matrix structures, magnetic field intensities and slurry ratios has been completed and

High Efficiency Wet Drum Type Magnetic Separator for Mineral Iron Ore

Wet drum permanent magnetic separator is suitable for mine, coal preparation plant etc. use weak wet magnetic field to sort out the strong magnetic ore, or e...

Effective Processing of Specularite Ore by Wet Magnetic Separation

DOI: 10.17350/hjse Corpus ID: ; Effective Processing of Specularite Ore by Wet Magnetic Separation and Reverse Flotation Techniques @article{AlDhubaibi2019EffectivePO, title={Effective Processing of Specularite Ore by Wet Magnetic Separation and Reverse Flotation Techniques}, author={Ammar Mahdi

Wet Drum Magnetic Separator Sepor, Inc

Our Wet Drum Magnetic Separators are available in the following drum diameters: 15″, 30″ and 36″. Standard drum lengths are: 15″, 24″, 36″, 48″, 60″, 72″, 84″, 96″, 108″ and 120″. Five basic factors influence proper

Intensity Magnetic Separator an overview ScienceDirect Topics

The Jones wet high-intensity magnetic separator (WHIMS) was developed in 1956.The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron-core electromagnet, a vertical shaft with two (or more) separating rings, a driving system, and feeding and product collection devices. Grooved plates made of magnetic conductive

Magnetic Separators MetallurgistMineral Processing Engineer

2016年5月31日The Dings-Crockett High Intensity (Wet Type) Submerged Belt Magnetic Separator is designed for wet separations. It has found wide application in the concentration of magnetite, ilmenite, and other materials of similar magnetic susceptibility where it gives an amazingly clean-cut separation of tailings, middlings, and concentrates.

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

Effective Processing of Specularite Ore by Wet Magnetic

The processing a specularite sample using wet magnetic separation and reverse flotation method was studied. During the magnetic separation process, particle size was -2000 µm and...

Effective Processing of Specularite Ore by Wet

2019年9月30日On the other hand, because oxidized iron ores like martite, hematite, specularite, limonite, and siderite are weakly magnetic, high-intensity magnetic separators and high-gradient magnetic

Effective Processing of Specularite Ore by Wet Magnetic Separation

DOI: 10.17350/hjse Corpus ID: ; Effective Processing of Specularite Ore by Wet Magnetic Separation and Reverse Flotation Techniques @article{AlDhubaibi2019EffectivePO, title={Effective Processing of Specularite Ore by Wet Magnetic Separation and Reverse Flotation Techniques}, author={Ammar Mahdi

MMPB-470O Wet Drum Separators Eriez

Wet drum magnetic separators are the most vital part of the upgrading process in magnetite concentration. The upgrading of primary magnetite is always accomplished with wet drum separators. Mill feed is typically upgraded to 65+ percent magnetic iron using a series of wet drum magnetic separators. The number of magnetic separation

Wet Drum Magnetic Separator Sepor, Inc

Our Wet Drum Magnetic Separators are available in the following drum diameters: 15″, 30″ and 36″. Standard drum lengths are: 15″, 24″, 36″, 48″, 60″, 72″, 84″, 96″, 108″ and 120″. Five basic factors influence proper

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)

Product Description: SLon has finished the design of the largest SLon-5000 VPHGMS (WHIMS), whose single unit capacity can reach up to 950t/h. In the past 30 years, SLon has focused on the innovation and promotion of mineral processing techonology, and completed the design, manufacture and utilization of over 70 models of VPHGMS.

Specularite Ore Beneficiation Studies BAS®

2022年6月30日In here specularite beneficiation studies that has been completed in the Eastern Aegean; high field intensity slon type electromagnetic separators are used. Work on obtaining the final product %65Fe with maximum product recovery with different matrix structures, magnetic field intensities and slurry ratios has been completed and

High Efficiency Wet Drum Type Magnetic Separator for Mineral Iron Ore

Wet drum permanent magnetic separator is suitable for mine, coal preparation plant etc. use weak wet magnetic field to sort out the strong magnetic ore, or e...

Magnetic Separators MetallurgistMineral

2016年5月31日The Dings-Crockett High Intensity (Wet Type) Submerged Belt Magnetic Separator is designed for wet separations. It has found wide application in the concentration of magnetite, ilmenite, and other

Wet High Intensity Magnetic Separation

2017年6月4日WHIM is the short acronym for Wet High Intensity Magnetic Separation . At present, most U.S. iron raw materials are produced from magnetic taconites, which are ground to a nominal minus

Optimizing the performance of wet drum magnetic separators

2010年11月1日Optimizing the performance of wet drum magnetic separators. M. Dworzanowski. Published 1 November 2010. Physics, Materials Science. Journal of The South African Institute of Mining and Metallurgy. A ferromagnetic material when exposed to a magnetic field becomes magnetized but when it is removed from the magnetic field it

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

Intensity Magnetic Separator an overview ScienceDirect Topics

The Jones wet high-intensity magnetic separator (WHIMS) was developed in 1956. The structure of the Jones separator is shown in Figure 9.6 and consists mainly of an iron-core electromagnet, a vertical shaft with two (or more) separating rings, a driving system, and feeding and product collection devices.

Effective Processing of Specularite Ore by Wet Magnetic Separation

Enter the email address you signed up with and we'll email you a reset link.

- 铜精矿含银的计价

- Used Concrete Floor Grinder For Sale

- 实验室 磨煤机

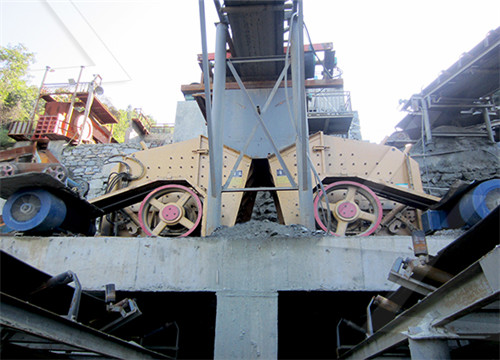

- 大型石灰石破碎设备

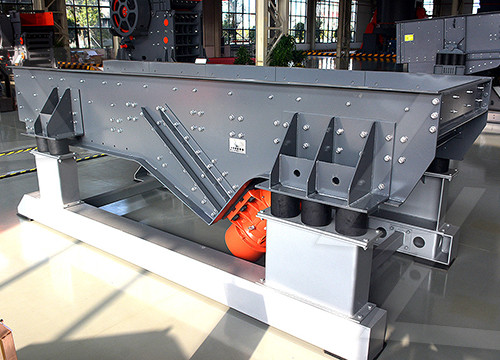

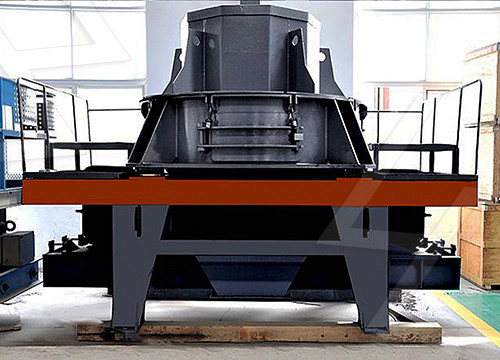

- Homogeneous Granularity Sand Machine Lime Stone Sand Making Machine

- 挖掘机破石子

- 压式破碎机

- 黑龙江粉碎机的价格

- 热力发电场热力系统分析计算论文

- 五矿鲁中沙宝珍出事

- 化肥的粉碎

- 成套河卵石制砂机

- Crushing And Identifying Copper

- 加工理石需要什么设备

- Large Big Stone Crushing Plant Price, Kenya Gold Stone Crusher Machine