Ball Mill Working And Construction Project

Ball Mill an overview ScienceDirect Topics

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig. 2.12).Such a ball mill body is expedient

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

2016年5月30日This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Ball mill is a

Case Study Cobré Panama Project Lycopodium

As production capacity at Cobré Panama continues to be developed to ultimately process 100 Mtpa of ore, Lycopodium is providing engineering, design, procurement and construction support services for the mine’s

Ball mill SlideShare

2015年4月24日5. The ball mill is used for grinding materials such as coal,pigments,and fedspar for pottery. Grinding can be carried out in

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 L-capacity grinding chamber made of an abrasion-resistant elastomer, put in vibrating motion by high-tensile steel springs [28]....

Ball Mill Principle, Construction, Uses, Advantage

2021年8月17日C. Ball mill is an open system, hence sterility is a question D. Fibrous materials cannot be milled by ball mill. 10. What particle size can be obtained through

The working principle of ball mill Meetyou Carbide

2019年5月22日22 May, 2019. The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the

Construction and Working of Ball Mill Solution Pharmacy

2021年5月11日Construction of Ball Mill The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis. The cylinder can be made of metal, porcelain, or rubber. Inside the

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日A ball mill efficiently operated performs a wide variety of services. In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the Steel

Ball Mill an overview ScienceDirect Topics

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig. 2.12).Such a ball mill body is expedient because efficiency is appreciably increased. Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge outlet; the helix

Design Method of Ball Mill by Discrete Element Method

1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis-crete element method, we must first be able to repro-duce the balls’ motion in the ball mill using simula-tions. Kano et al.8) have made it clear that it is possible to reproduce the ball motion when the solid material is

Project 079 Making a Ball Mill YouTube

2018年3月31日The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

Ball Mill SlideShare

2015年11月30日PRINCIPLE: A ball mill works on the principle of impact and attrition. size reduction is done by impact as the balls drop from near the top of the shell. 7. CONSTRUCTION: Wet or dry ball mill grinding

球磨是干什么的,详解球磨工艺,解开我多年的疑惑! 知乎

球磨机是原料在被开采或者破碎成小块以后,再次进行破坏让其颗粒变得更小的设备,从其名字也就可以理解,球磨机是在一个封闭的圆筒内装有钢球,通过圆筒的旋转让钢球从高处落下与要粉碎的物料碰撞,以达到将物料研磨变细的目的。 球磨机主要在新型建筑材料,水泥,耐火材料,有色金属以及玻璃陶瓷的生产过程中广泛应用。 球磨机具有生产效率高,

Ball Mill Working Principle And Main Parts GitHub Pages

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken

How a Grate Discharge Ball Mill Works Mineral Processing

2015年8月13日How a Grate Discharge Ball Mill Works Here I try to explain how ground slurry is discharged from a grate ball mill (or SAG). How it works is, the slurry flows across the grate as it would a screen panel. On the other side of the grate/screens are veins like a pump impeller. As the mill turns/rotates the slurry is “pumped” out and discharged.

DIY Ball Mill Plans Homemade Rod Mill Drawing

2016年10月31日DIY Ball Mill Plans Homemade Rod Mill Drawing homemade ball mill plans By this drawing, it is suggested that a typical homemade laboratory rod mill or ball mill might be fabricated from 20 cm (8 inches) diameter schedule-40 type 316 stainless steel pipe and would be about 38 cm (15 inches) long.

BALL MILL PowerPoint PPT Presentation PowerShow

what is a ball mill, its constructuction description, working,etc A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on PowerShow id: 7175b9-MGY2M Ball Grinding Mill Market SWOT Analysis, New Projects, Investment Feasibility and Return to 2020 Market Analysis of Ball Grinding Mill. It has covered the world’s

BALL MILL CONSTRUCTION PRINCIPLE WORKING SIZE

2021年6月8日This video discuss about the ball mill working,principle and construction which is helpful for exams.CONNECT WITH PHARMACY INDIA FOR LATEST UPDATES 👉FACEB...

Working Principle of Ball Mill LinkedIn

2018年1月22日Working Principle. This machine is a horizontal cylindrical rotating device, external gear drive, two positions, lattice-type ball mill. Materials from the feed device through the hollow shaft

What Is a Ball Mill? Blog Posts OneMonroe

2020年3月10日Ball mills work by using balls to grind materials. Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis. As the ball bill rotates, the balls bounce around while striking the enclosed material.

EX-4.AP SEC

Minerals Pty Ltd has received the above-referenced DRAFT INSTRUMENT OF AGREEMENT to supply both a SAGBall Mill for the Lihir MOPU Project. Chute work ahead of the mill retractable feed chute and Appendix C, Mill Gearing, for a more detailed description of design and construction requirements for the mill. The mill pinion

Blackwater Goldmine Home

The project is in the final permitting stage and anticipates a start of major works construction in Q1, 2023. The Project is located in central British Columbia, approximately 160 km southwest of Prince George and 446 km northeast of Vancouver. (“SMC”) on the new drill core, Bond rod mill work index (“RWi”), Bond ball mill work

Design Method of Ball Mill by Discrete Element Method

1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis-crete element method, we must first be able to repro-duce the balls’ motion in the ball mill using simula-tions. Kano et al.8) have made it clear that it is possible to reproduce the ball motion when the solid material is

Project 079 Making a Ball Mill YouTube

2018年3月31日The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

The operating principle of the ball mill

2017年2月8日The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being

Working Principle of Ball Mill LinkedIn

2018年1月22日Ball mill widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal beneficiation and glass ceramic production industries, all...

Ball Mill Working Principle And Main Parts GitHub

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time,

How a Grate Discharge Ball Mill Works Mineral

2015年8月13日How a Grate Discharge Ball Mill Works Here I try to explain how ground slurry is discharged from a grate ball mill (or SAG). How it works is, the slurry flows across the grate as it would a screen

BALL MILL CONSTRUCTION PRINCIPLE WORKING SIZE

2021年6月8日This video discuss about the ball mill working,principle and construction which is helpful for exams.CONNECT WITH PHARMACY INDIA FOR LATEST UPDATES 👉FACEB...

The 6 phases of construction project management (CPM)

2022年11月27日Construction project management (CPM) is the process of managing, regulating, and supervising construction processes. CPM can vary from a single project to managing an entire construction management company.

CORE Aggregating the world’s open access research s

CORE Aggregating the world’s open access research s

EX-4.AP SEC

Minerals Pty Ltd has received the above-referenced DRAFT INSTRUMENT OF AGREEMENT to supply both a SAGBall Mill for the Lihir MOPU Project. Chute work ahead of the mill retractable feed chute and Appendix C, Mill Gearing, for a more detailed description of design and construction requirements for the mill. The mill pinion

Blackwater Goldmine Home

The project is in the final permitting stage and anticipates a start of major works construction in Q1, 2023. The Project is located in central British Columbia, approximately 160 km southwest of Prince George and 446 km northeast of Vancouver. The Project is accessible by major highway and access/service roads.

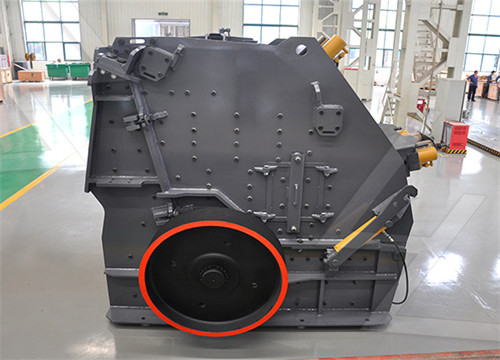

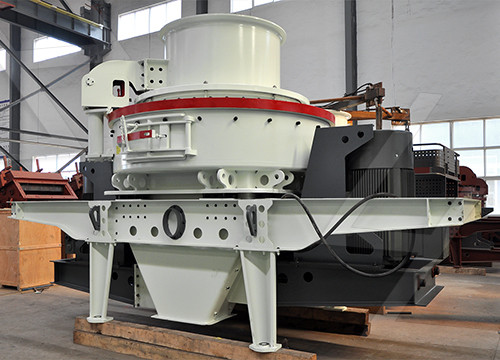

Detailed Construction And Working Of A Flour Mill

working principle of radial working principle mode construction performance of ball mill. such as XZM series ultrafine mill's output size can reach mpl crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher to cone crusher and

Millwork vs. Casework: What is the Difference and Comparison

2018年11月2日The Difference between Millwork and Casework. Major difference between the two is that millwork is custom, while casework isn’t. Casework pieces are not made to fit the spaces, they are rather made after taking the specific geometrical dimensions of the space. There, of course, can be multiple variants and customization of colors, surface

Ball Charging System — Material Handling Engineering,

Auto Ball Charging System. with Patented Ball Feeding Indexer. The Auto Ball Charging system was developed to make the loading of balls into a Ball Mill safer and easier. By using a fixed hopper along with a machine to supply balls at a fixed rate, the system. harm’s way. All handling of the balls. can be done by a loader and placed in the

- 河南巩义磨机中国供应商

- Equipment For Small Scale Gold Mining

- 立磨磨辊漏风

- 食用石膏粉的作用

- Rock Crushers Made In Vietnam

- Quartz Ore Crushing Equipment Reliable Quality

- 石头一方多钱碎石

- 坚井锤击式磨煤机燃油设备的运行和检修

- Cm Hammer Mill Of Quartz Crusher Manufacturers

- Sea Sand Washing Plant Manufacturers In India

- 采沙制沙设备

- 头发加工细丝机器

- 铋金属计价系数

- 双螺旋给料机图纸

- Media Laporan Proyek Bola Grinding