Types Of Flotation Cell With Details

Flotation Cell an overview ScienceDirect Topics

Flotation Cell A flotation cell designed to treat the coarse cyclone underflow is the Skimair® or Flash flotation cell. From: Mineral Processing Design and Operations (Second Edition), 2016 Related terms: Lignite Impeller Ultrasonics Hydrocyclone Coal Particle

进一步探索

Different Types of Flotation Cells Mineral ProcessingM(PDF) Flotation Technology Handbook Academia.edu(PDF) Flotation Equipment and Processes ResearchGate(PDF) Fundamental principles of froth flotation ResearcFlotation Circuits Diagrams Mineral ProcessingMetallurgy根据热度为您推荐•反馈

Flotation an overview ScienceDirect Topics

Flotation is a technique, widely used by the mining industry, for the separation of minerals, phosphates, or coal from gangue. Coal and minerals particle size and surface hydrophobicity are two main parameters that affect three key steps in froth flotation process: particle–bubble collision, adhesion, and detachment.

1 Froth Flotation Fundamental Principles

no flotation can occur. Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5. Figure 5: Simplified schematic of a conventional flotation cell. The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator.

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

flotation cell rotor. Traditionally flotation plant design blower selection and control has been based on using an oversized positive displacement blower, or an industrial fan, with any excess air discharged to atmosphere. While easy to select and design, this type of circuit contains inefficiencies especially when it comes to energy consumption.

Flotation Cell Design: Application of Fundamental

cells and details of this design will be discussed later in this article. The top section of the disc connects to a drive shaft which in turn connects to the pulley/gear-motor drive assembly. The impeller is located in the centre of the cell cross-section with its II/FLOTATION/Flotation Cell Design: Application of Fundamental Principles 1505

Flotation Cells Mineral ProcessingMetallurgy

2015年12月14日Flotation Cells. More ores are treated using froth flotation cells than by any other single machines or process. Non-metallics as well as metallics now being commercially recovered include gold,

Flotation cells types. LinkedIn

2021年11月19日Rougher cells. These cells receive the head pulp that comes from the mill conditioners, in them most of the objective minerals float, from these cells are obtained both "provisional"...

Flotation Froth an overview ScienceDirect Topics

Conventional flotation cells allow a small amount of clay slimes to be recovered with the water that reports to the froth product. A column cell (Fig. 19) virtually eliminates this problem by washing the clay slimes from the froth using a countercurrent flow of wash water. This feature allows columns to produce higher quality concentrate coals

Review on advances in mineral processing technologies suitable

2022年4月1日The use of a gently uprising, aerated fluid greatly reduces the turbulence commonly found in other flotation cells, allowing the effective flotation of coarser particles (Kohmuench et al., 2018). Fluidised bed flotation is advantageous as it can reduce the need for finer grinding, reduce grinding costs, and it accepts feed with very high solid

Flotation Cell Design: Application of Fundamental Principles

cells and details of this design will be discussed later in this article. The top section of the disc connects to a drive shaft which in turn connects to the pulley/gear-motor drive assembly. The impeller is located in the centre of the cell cross-section with its II/FLOTATION/Flotation Cell Design: Application of Fundamental Principles 1505

Flotation Cell Working Principle, Type, Influencing Factors

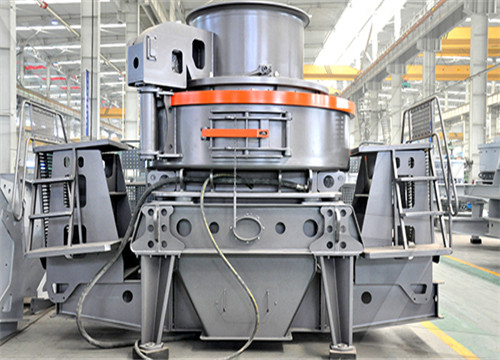

2022年8月18日The common types of mining flotation cells are mechanical agitation flotation cell, air-inflation agitation flotation cell and air-inflation flotation cell. (1) Mechanical agitation flotation cell This flotation machine is a flotation cell with self-air-inflation and self-priming pulp.

What Are Column Flotation Cells? indres

2019年2月6日The other type of flotation cells is a column cell. Column cells are tall round tanks that use compressed air to create air bubbles via spargers or cavitation tubes. These cells are used to perform mineral

Flotation cells types. LinkedIn

2021年11月19日Flotation cells types. Report this post ECN Automation ECN Automation Published Nov 19, 2021 + Follow As we mentioned in previous articles, the mineral flotation is an operation in which the

Flotation Cell Impeller Types 911metallurgist

2016年4月20日Types of Drives The “Sub-A” was the first flotation machine to use the Multi-V-Belt Horizontal Drive, vhich has proved so successful. “Sub-A” Flotation Cells have been carefully designed to be driven either by a motor and

SF Flotation Cell, Floatation Method, Flotation Machine, Flotation Cell

SF flotation cell could improve concentrate grade 4-6%, recovery rate 8% and capacity 12%, and it is widely used in flotation process as flotation machine. marketing@ytxinhai. 0086 . Language. Overflow Type Ball Mill. More Details. Classifying. Spiral Classifier

Functions Of Flotation Reagents: Explain Their Types And

2023年2月17日Depressants are flotation reagents that prevent certain minerals from attaching to air bubbles, causing them to sink to the bottom of the flotation cell. This separates the desired minerals from

Bar Flotation Cell-Global (North America, Europe, Asia-Pacific,

Report Summary: The report titled "Bar Flotation Cell Market" offers a primary overview of the Bar Flotation Cell industry covering different product definitions, classifications, and participants in the industry chain structure. The quantitative and qualitative analysis is provided for the global Bar Flotation Cell market considering competitive landscape,

The Depressing Effect of Kaolinite on Molybdenite Flotation in

2020年6月26日The molybdenite sample (size range −88 + 44 µm) used in this work was obtained from an industrial molybdenum concentrate, which was initially washed with sodium hydrosulfide (NaSH) and acetone to remove flotation collectors and

Small Scale Multi-function Portable Flotation Device Xfd Small

Small Scale Multi-function Portable Flotation Device Xfd Small Cobalt Concentrator For 35mesh Ore Test Flotation,Find Complete Details about Small Scale Multi-function Portable Flotation Device Xfd Small Cobalt Concentrator For 35mesh Ore Test Flotation,Small Cobalt Concentrator,Portable Flotation Device,Xfd from Supplier or

Jameson Cell Glencore

Jameson Cell has 100% accurate scale-up reliability and is the real-word specification in any and all duties within a flotation circuit: rougher and scavenger duty. cleaner and cleaner scavenger duty. In fact, a single Jameson Cell has successfully replaced a traditional circuit of cells; and unlike other competing cells, it has no moving parts.

2 Types of Froth Flotation Processes Mining-pedia

2020年3月9日Stage froth flotation process is mainly because the ore has uneven disseminated grain size, which is necessary to be carried out grinding operation after a stage froth flotation process, that is known as the two-stage froth flotation process. By that analogy, this is multiple stage froth flotation.

Flotation Froth an overview ScienceDirect Topics

Conventional flotation cells allow a small amount of clay slimes to be recovered with the water that reports to the froth product. A column cell (Fig. 19) virtually eliminates this problem by washing the clay slimes from the froth using a countercurrent flow of wash water. This feature allows columns to produce higher quality concentrate coals

Jameson Cell Glencore

Jameson Cell has 100% accurate scale-up reliability and is the real-word specification in any and all duties within a flotation circuit: rougher and scavenger duty. cleaner and cleaner scavenger duty. In fact, a single

Investigation of the reverse flotation of hematite in three different

2018年9月19日These limitations have resulted in developing a novel flotation cell (Pyke et al., 2003;Koh et al., 2003; Hoseinian et al., 2019) so-called the oscillating grid flotation cell (OGC). It was

(PDF) Optimization of Rotor Geometry for a Type of Self-Suction

2016年4月20日PDF The hydrodynamics generated by forward-rotor (F-rotor), radial-rotor (R-rotor), and backward-rotor (B-rotor) geometries in flotation cells are Find, read and cite all the research you

Flotation cells types. LinkedIn

2021年11月19日Flotation cells types. Report this post ECN Automation ECN Automation Published Nov 19, 2021 + Follow As we mentioned in previous articles, the mineral flotation is an operation in which the

Flotation Cell Impeller Types 911metallurgist

2016年4月20日Types of Drives The “Sub-A” was the first flotation machine to use the Multi-V-Belt Horizontal Drive, vhich has proved so successful. “Sub-A” Flotation Cells have been carefully designed to be driven either by a motor and

PFD Selection, Use, WearCare United States Coast

Adult universal size PFDs are required to fit a range of chest sizes of at least 75 130 cm (30 52 inches). Manufacturers are shown in these lists for Type I devices made with kapok flotation material and foam flotation

SF Flotation Cell, Floatation Method, Flotation Machine, Flotation Cell

SF flotation cell could improve concentrate grade 4-6%, recovery rate 8% and capacity 12%, and it is widely used in flotation process as flotation machine. marketing@ytxinhai. 0086 . Language. Overflow Type Ball Mill. More Details. Classifying. Spiral Classifier

Small Scale Multi-function Portable Flotation Device Xfd Small

Small Scale Multi-function Portable Flotation Device Xfd Small Cobalt Concentrator For 35mesh Ore Test Flotation,Find Complete Details about Small Scale Multi-function Portable Flotation Device Xfd Small Cobalt Concentrator For 35mesh Ore Test Flotation,Small Cobalt Concentrator,Portable Flotation Device,Xfd from Supplier or

Bar Flotation Cell-Global (North America, Europe, Asia-Pacific,

Report Summary: The report titled "Bar Flotation Cell Market" offers a primary overview of the Bar Flotation Cell industry covering different product definitions, classifications, and participants in the industry chain structure. The quantitative and qualitative analysis is provided for the global Bar Flotation Cell market considering competitive landscape,

Flotation characteristics of two different types of ilmenite with

2014年6月1日The flotation characteristics of native ilmenite (IL-N) and beach placer ilmenite (IL-BP) with sodium oleate (NaOL) were investigated through micro-flotation tests, zeta-potential measurements, absorbed amount measurements, and Fourier transform infrared spectroscopic (FT-IR) analysis. The results show that IL-N can float well at the

Gold Processing Plant Prominer (Shanghai) Mining Technology

I. Physical Gold processing technology: Crushing&Grinding Gravity Separation Flotation Process Agglomeration II. Chemical Gold processing technology: Carbon in Leaching (CIL) Carbon in Pulp (CIP) Heap Leaching (Dump leaching) Desorption Electrolysis Process Smelting Refining Processing Gravity Separation Flotation CIL or CIP Heap Leaching

Flotation Reagent an overview ScienceDirect Topics

The column flotation cell which has achieved success in the mineral industry was introduced to the coal industry in the 1990s. The machine consists of a long (∼6 m) vertical tube ranging from 2.4 to 3.0 m in diameter. Figure 3 shows a

PFD Guidelines 5 Types of Personal Flotation Devices

2019年2月1日22.0 (Fully Inflated) / 7.5 (Deflated) V Special Use Device Inflatable. 22.0 to 34.0. V Special Use Device Buoyant. 15.5 22.0. Inflatable devices depend on flexible air chambers which can be filled with air or other gas (typically carbon dioxide) for flotation. Buoyant devices rely on buoyant material such as “Kapok” (fiber