Manganese Ore Mining Processing Ethiopia Belgium

Manganese Mining and Processing: Everything you Need to Know

Most manganese mining occurs in open pits. Although there are processes in place to mine manganese nodules in the ocean floor, they cannot

IMPC 2016: XXVIII International Mineral Processing

1. INTRODUCTION COMILOG, that forms a part of the French mining and metallurgical group ERAMET, extracts manganese (Mn) ore in Moanda, Gabon and produces Mn

Manganese Mining and Processing for Investors, Explained

Processing the Ore Pure manganese is produced by hydrometallurgical and electrolytic processes, while ferromanganese and silicomanganese are produced by the smelting of ores in a blast furnace or, more commonly,

Manganese Ore Processing Mineral Processing

2016年4月27日The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock The flowsheet incorporates a

Manganese Beneficiation Process, Equipment Mineral

Manganese ore magnetic separation is mainly suitable for manganese oxide ore and manganese carbonate ore beneficiation, generally referred to as an auxiliary beneficiation process, but dry strong magnetic separation

Manganese Mining Process Manganese Mining Mining

The manganese ore magnetic separator produced by the Shicheng County Mining Machinery Plant in Jiangxi Province is a dry type strong magnetic separator, which uses

7 Common Manganese Mining Processes

2019年11月13日The manganese mining process that used to deal with manganese oxide ores usually need to crush the ores into 0-6mm to 0-10mm, and then classify them. The coarse minerals are sent to jigging

Our Operations Tshipi

Mining. Tshipi operates one of the largest manganese mineral assets in the world. The Tshipi Borwa mine is a leading manganese ore producer with an established and efficient export infrastructure, including a 8km private rail

Study on the Gravity Processing of Manganese Ores

Manganese ores from Sindirgi Balikesir region, Kinik district, Turkey are low grade types and need beneficiation to utilize them in ferromanganese and chemical industry.

Global manganese production by country 2021 Statista

2022年6月27日Global manganese mine production 2021, by country. South Africa is the world's largest producer of manganese by far, with production amounting to 19.16 million metric tons in 2021. Gabon was the

IMPC 2016: XXVIII International Mineral Processing

1. INTRODUCTION COMILOG, that forms a part of the French mining and metallurgical group ERAMET, extracts manganese (Mn) ore in Moanda, Gabon and produces Mn alloys for the steel industry.

Hydrometallurgical Processing of Manganese Ores: A Review

2011年1月1日Effects of the mass ratio of manganese ore to sawdust, roasting temperature and time, leaching temperature and time, leaching agent concentration and liquid-solid ratio were studied. 97.71% of

Our Business consmin

We are the second largest manganese ore producer in the world by volume, with mining operations in Australia and Ghana and headquartered in Jersey. Our principal activities are the exploration, mining, processing and sale of manganese ore. Manganese is an essential element in global growth. Over 90% of manganese ore worldwide is consumed

Manganese Beneficiation Process, Equipment Mineral Processing

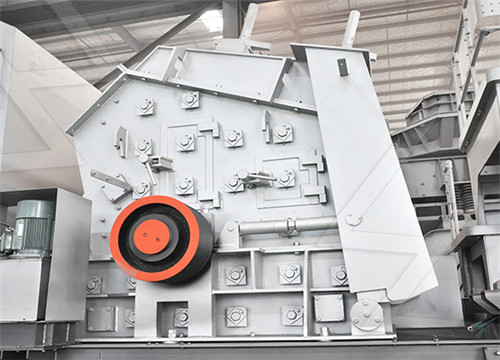

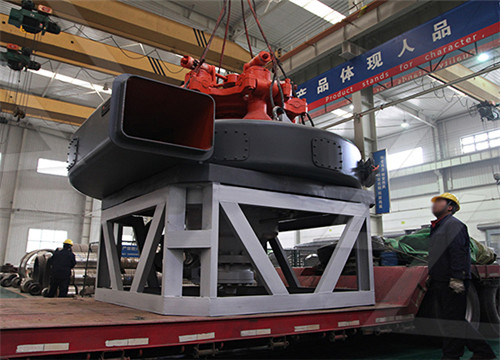

The manganese ore beneficiation plantequipment is a production line that processes the manganese ore mined from the mine to improve the grade of the manganese ore. Application: Manganese oxide ore, carbonate manganese ore, ferromanganese ore, manganese-containing iron ore and multi-metal composite manganese ore

Manganese Mining Process Manganese Mining Mining

Manganese ore magnetic separator is mainly used for magnetic beneficiation of minerals such as medium-sized, fine-grained manganese oxide ore and manganese carbonate ore mining process. It has the advantages of high efficiency, energy saving, environmental protection, dry beneficiation and waterless operation. 1.2 Manganese ore jig concentrator

5 Commonly Used Manganese Processing Methods Mining

2021年6月29日Because the density of manganese oxide ore such as pyrolusite, pyrolusite, and brown manganese ore is about 4g/m³, which is significantly different from the density of silicate gangue, most of them can use gravity separation. Manganese carbonate ore mostly adopts the combined process of dense medium and strong

How to Extract the Manganese Ore? Mining-pedia

2019年7月15日The purpose of manganese ore calcination process is: First, the high-priced manganese oxide is reduced to low-priced manganese oxide, which facilitates the dissolution of manganese into an ionic state during wet leaching process; Second, the weak magnetic iron minerals is reduced into ferromagnetic magnetite or maghemite (γ

Study on the Gravity Processing of Manganese Ores

Manganese ores from Sindirgi Balikesir region, Kinik district, Turkey are low grade types and need beneficiation to utilize them in ferromanganese and chemical industry. Mineralogical and chemical characterization of ores from this region indicated their susceptibility to manganese enrichment. In this study, the optimum gravity beneficiation

Iron and Manganese Ore Deposits: Mineralogy,

supplier of iron and manganese ore. The global manufacture of 780 million tons of raw steel in 1999, for example, required the mining of 992 million tonnes of iron ore and approximately 18 million tonnes of manganese ore. This production is from a nonrenewable reserve base. The size of this reserve base is certainly finite, but estimates

Manganese Mining and Processing for Investors in Manganese

2021年3月9日CEO Martin Kepman It’s imperative to understand the importance of ethically sourced, high purity Manganese and the technological mining processes required to extract, refine, purify while...

High-purity manganese facing phenomenal demand growth,

2022年6月24日The car companies that are basing their electrification strategy around manganese produce 27-million vehicles a year, and a significant factor is the weight of the manganese that will be...

Investing in Manganese Future-Friendly Mining Idea

2021年8月24日Saint-Laurent,Aug. 24, 2021 (GLOBE NEWSWIRE) -- Investing in Manganese is a Future-Friendly Mining Idea Explains Martin Kepman CEO of Manganese X Energy! Manganese will affect how we...

South Africa Manganese Mining Industry Report 2020

2021年3月4日Mining of Manganese in South Africa: South Africa was the world's largest producer and exporter of manganese ore in 2019, accounting for 30% of global production and almost 50% of global exports

Global manganese production by country 2021 Statista

2022年6月27日Global manganese mine production 2021, by country. South Africa is the world's largest producer of manganese by far, with production amounting to 19.16 million metric tons in 2021. Gabon was the

IMPC 2016: XXVIII International Mineral Processing

1. INTRODUCTION COMILOG, that forms a part of the French mining and metallurgical group ERAMET, extracts manganese (Mn) ore in Moanda, Gabon and produces Mn alloys for the steel industry.

Hydrometallurgical Processing of Manganese Ores: A Review

2011年1月1日Effects of the mass ratio of manganese ore to sawdust, roasting temperature and time, leaching temperature and time, leaching agent concentration and liquid-solid ratio were studied. 97.71% of

Our Business consmin

Our principal activities are the exploration, mining, processing and sale of manganese ore. Manganese is an essential element in global growth. Over 90% of manganese ore worldwide is consumed in the carbon and stainless steel industry, the majority of which is processed initially into manganese alloys.

Major MinesProjects Hotazel Complex

Samancor indirectly owns 74 per cent of Hotazel Manganese Mines (HMM), which gives South32 Limited its ownership interest of 44.4 per cent. The remaining 26 per cent of HMM is owned by Broad-Based Black Economic Empowerment (B-BBEE) entities. Anglo American Plc effective ownership interest in HMM is 29.6%.

Manganese Beneficiation Process, Equipment Mineral Processing

Manganese ore magnetic separation is mainly suitable for manganese oxide ore and manganese carbonate ore beneficiation, generally referred to as an auxiliary beneficiation process, but dry strong magnetic separation can also be used to treat manganese ore in areas without water or water shortage.

5 Commonly Used Manganese Processing Methods Mining

2021年6月29日Because the density of manganese oxide ore such as pyrolusite, pyrolusite, and brown manganese ore is about 4g/m³, which is significantly different from the density of silicate gangue, most of them can use gravity separation. Manganese carbonate ore mostly adopts the combined process of dense medium and strong

Study on the Gravity Processing of Manganese Ores

Manganese ores from Sindirgi Balikesir region, Kinik district, Turkey are low grade types and need beneficiation to utilize them in ferromanganese and chemical industry. Mineralogical and chemical characterization of ores from this region indicated their susceptibility to manganese enrichment. In this study, the optimum gravity beneficiation

Iron and Manganese Ore Deposits: Mineralogy,

supplier of iron and manganese ore. The global manufacture of 780 million tons of raw steel in 1999, for example, required the mining of 992 million tonnes of iron ore and approximately 18 million tonnes of manganese ore. This production is from a nonrenewable reserve base. The size of this reserve base is certainly finite, but estimates

High-purity manganese facing phenomenal demand growth,

2022年6月24日The car companies that are basing their electrification strategy around manganese produce 27-million vehicles a year, and a significant factor is the weight of the manganese that will be...

South Africa Manganese Mining Industry Report 2020

2021年3月4日Mining of Manganese in South Africa: South Africa was the world's largest producer and exporter of manganese ore in 2019, accounting for 30% of global production and almost 50% of global exports

[Pollution Properties and Ecological Risk Assessment of Heavy

2022年2月8日The principal component analysis showed that the sources of Cd, Mn, and Zn in the farmland soil were related to the manganese ore mining, whereas the source of As in the farmland soil might originate from agricultural activities. The pollution area was at a heavy pollution level, and the main pollution factors were Cd, Mn, and Zn. The Cd in the

10tph manganese ore processing plant walker

2021年9月2日A customer is interested in a jigging plant of about 10 tph to process manganese ore. They think the material is pyrolusite with silica inclusions. 1. Raw materials: Manganese Ore(pyrolusite with silica inclusions) 2. Feeding Size: 200mm 3. Output Size: 0-20mm 4. Capacity: 10tph. Preliminary manganese mining process flow

Manganese Archives NS Energy

Gold Lion will acquire a 50% stake in the property, Elcora will use the proceeds to start ore Mining Manganese Major Commodities. BASF expands production capacity in China for industry-leading cathode active materials and achieves multi-ton scale manufacturing for manganese-rich products.