Ball Mill Design In Mining Project

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill

根据热度为您推荐•反馈

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

Ball Mill Design/Power Calculation Mineral Processing

2015年6月19日The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be

(PDF) DYNAMIC ANALYSIS FOR BALL MILL FOUNDATION

2019年1月30日Ball mill shell supported design In mining industry, ball mills normally operate w ith an approximate ball charge of 30% with

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 L-capacity grinding chamber made of an abrasion-resistant

Hanlon Mining Ball Mill Expansion Project Hanlon

Hanlon Mining Ball Mill Expansion Project Our Mining Client desired increased production from their milling operations, HE is currently providing the Engineering, Procurement Assistance and Construction Management

Ball Mill And Air Classifier Production System EPIC Powder

Product Feature. 01. With Al2O3 or silex or steel lining.Mainly designed with overflow type or grate discharge wall. 02. With air through the mill or with air-swept principle to get cooler

Application of Silver Ore Ball Mill in 300t/d Morocco Silver

The main equipment AGICO GROUP equipped for this silver mine mining project is a silver ore ball mill.The converted silver ore processing plant has a daily production capacity of 300 tons, the silver recovery rate has

How to design a Ball Mill GrindingClassification Circuits

You also need a rod mill work index to design a ball mill operating on a coarse feed, above about 4 mm. Q1: You design for a typical percentage of critical speed, usually 75% of

Ball Mill for Sale Mining and Cement Milling Equipment

These industrial ball mills are widely used in cement manufacturing, mining, metallurgy, building materials, chemical industry, electric power and other industries. They are also popular in the fields of large non-metallic

AMIT 135: Lesson 7 Ball MillsCircuits Mining

Ball Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 5.24 meters and length of 8.84 meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter.

Integrating geometallurgical ball mill throughput predictions into

2022年11月1日Request PDF Integrating geometallurgical ball mill throughput predictions into short-term stochastic production scheduling in mining complexes This article presents a novel approach to

Ball Mill Design/Power Calculation Mineral

2015年6月19日The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired

(PDF) A Statistical Comparison of Bond Ball Mill Grindability

2021年9月8日Colorado School of Mines Abstract and Figures Research was performed to make an objective comparison of Bond Ball Mill Grindability Work Index results derived from using two commercial testing...

Hanlon Mining Ball Mill Expansion Project Hanlon

Our Mining Client desired increased production from their milling operations, HE is currently providing the Engineering, Procurement Assistance and Construction Management services to increase the

ball mill Archives International Mining

The project, owned 77.28% by Galena Mining, is set to turn into a mine and processing facility with a 16-year life producing a high-value, high-grade lead-silver concentrate containing around 95,000 t/y of lead and 805,000 oz/y of silver after ramp-up. First production is scheduled for 2023.

17 Signs of Problems with Ball Mills: Quickly

2023年2月15日The ball mill starts to discharge a great amount of ore blocks. The machine operation sound is dull, and there is no sounds of steel ball impacting. What causes the sign of "swollen belly" Feeding volume

sbm ball mill design in mining project.md main GitLab

Projects Groups Snip Sign up now Login; Sign in / Register Toggle navigation Menu. S sbm Project information Project information Activity Labels Members Repository Repository Files Commits Branches Tags Contributors Graph Compare Issues 0 Issues 0 List Boards Service Desk Milestones Merge requests 0 Merge requests 0

Application of Silver Ore Ball Mill in 300t/d Morocco

The main equipment AGICO GROUP equipped for this silver mine mining project is a silver ore ball mill.The converted silver ore processing plant has a daily production capacity of 300 tons, the silver recovery rate has

Case Study Cobré Panama Project Lycopodium

As production capacity at Cobré Panama continues to be developed to ultimately process 100 Mtpa of ore, Lycopodium is providing engineering, design, procurement and construction support services for the mine’s

Planetary Ball Mill JXSC Machine

The planetary ball mill consists of 4 grinding jars, stainless steel pressure rods, viewing windows, hatch covers, planetary discs, and control systems. Filled with loose grinding balls, two superimposed rotary movements move the grinding jar. 【Working Principle】 The planetary ball mill is equipped with 4 grinding balls on a turntable.

Ball Mill Ball Mills WetDry Grinding DOVE

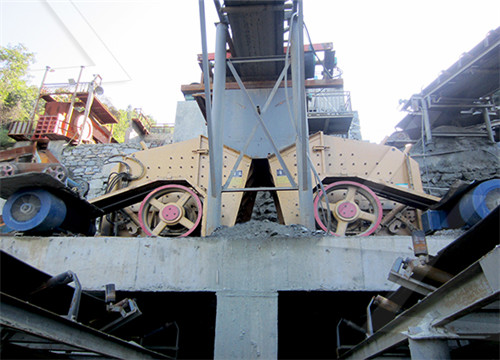

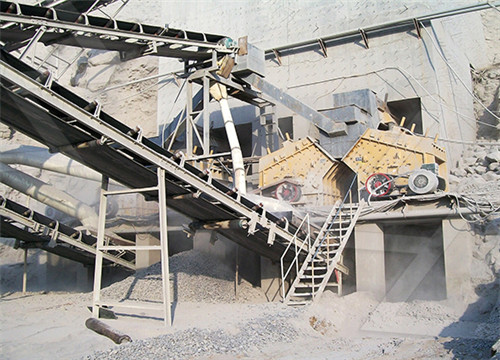

Ball Mill set up at the mining site. DOVE Ball Mills are deigned for either wet or dry grinding of materials, in various models, and in accordance to the processing and the crushing plant design, to cater to the liberation size of

sbm/sbm ball mill design in mineral processing project.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

What is the major step in the process of open-pit and underground mining?

2023年3月10日Published Mar 10, 2023. + Follow. Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of

AMIT 135: Lesson 7 Ball MillsCircuits Mining

Ball Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 5.24 meters and length of 8.84 meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter.

Integrating geometallurgical ball mill throughput predictions into

2022年11月1日Request PDF Integrating geometallurgical ball mill throughput predictions into short-term stochastic production scheduling in mining complexes This article presents a novel approach to

Case Study Cobré Panama Project Lycopodium

As production capacity at Cobré Panama continues to be developed to ultimately process 100 Mtpa of ore, Lycopodium is providing engineering, design, procurement and construction support services for the mine’s

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年5月30日Abstract and Figures. This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Ball mill is a cylindrical device that used to

Hanlon Mining Ball Mill Expansion Project Hanlon

Hanlon Mining Ball Mill Expansion Project Our Mining Client desired increased production from their milling operations, HE is currently providing the Engineering, Procurement Assistance and Construction Management

ball mill Archives International Mining

The project, owned 77.28% by Galena Mining, is set to turn into a mine and processing facility with a 16-year life producing a high-value, high-grade lead-silver concentrate containing around 95,000 t/y of lead and 805,000 oz/y of silver after ramp-up. First production is scheduled for 2023.

sbm/sbm ball mill design in mineral processing project.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

sbm ball mill design in mining project.md main GitLab

Projects Groups Snip Sign up now Login; Sign in / Register Toggle navigation Menu. S sbm Project information Project information Activity Labels Members Repository Repository Files Commits Branches Tags Contributors Graph Compare Issues 0 Issues 0 List Boards Service Desk Milestones Merge requests 0 Merge requests 0

Planetary Ball Mill JXSC Machine

The planetary ball mill consists of 4 grinding jars, stainless steel pressure rods, viewing windows, hatch covers, planetary discs, and control systems. Filled with loose grinding balls, two superimposed rotary movements move the grinding jar. 【Working Principle】 The planetary ball mill is equipped with 4 grinding balls on a turntable.

Application of Silver Ore Ball Mill in 300t/d Morocco

The main equipment AGICO GROUP equipped for this silver mine mining project is a silver ore ball mill. The converted silver ore processing plant has a daily production capacity of 300 tons, the silver recovery rate has

Codelco Andina changes the main motors of its ball

2020年2月24日Mining and metals refining Apr 26, 2021 Codelco Andina changes the main motors of its ball mills at its underground operation Metso Outotec called on its Field Services and A&CA teams to meet the

Grinding Mill Computer Model AusIMM

The tower mill calculation is based on the ball mill design sheet, but is simplified in that the mill design section is omitted. A simple tower mill factor of 70% allows the • Grinding Ball Selection FC Bond Mining Engineering May 1958 • Comparison of Work Indices CARowland Xth Int Min Proc Congress 1973 • Second SAG

Mining Ball Mill manufacturer--ZJH minerals

Ball mills will grind the crushed ores to be powder in proper size. The powder is the mixture of mineral and gangue. The power will be feeding the seperation equipment like flotation cells, magnetic separators ore shaking tables for separate the minerals. So ball mill is a key equipment for mining industry. ZJH minerals is a professional ball

Converting a ball mill from overflow to grate discharge Metso Outotec

2020年6月23日Grinding mills, including SAG (semi-autogenous grinding) mills and ball mills, consume approximately 60-70% of the total energy cost of the entire mining operation. The mills are installed with large motors, up to 20+MW, which impart the required energy to successfully process many tonnes per hour and grind the rock to a powder size