12m3 Jaw Crusher Size

Jaw Crushers high quality and reliability from RETSCH

Jaw Crusher BB 500 Material feed size*: < 110 mm Final fineness*: 90% < 0.5 mm Throughput*: 500 kg/h Product details Maximum throughput Jaw Crusher BB 600

进一步探索

Laboratory Jaw Crusher 911MetallurgistWhat is a Jaw Crusher? MEKA Crushing Equipment根据热度为您推荐•反馈

Jaw Crushers McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape

进一步探索

Used Jaw Crushers for sale. equipmentmore MView Jaw Crushers for Sale in Australia Machines4u根据热度为您推荐•反馈

Laboratory Jaw Crushers Gilson Co. GlobalGilson

LC-27 2.25x3in Laboratory Jaw Crusher reduces 2in (50mm) aggregate, ore, and rock materials to a product with 80% passing a No. 14 (1.4mm) sieve. Jaw opening easily adjusts down to 1mm minimum to closely

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a

Metso ® C Series™ jaw parts

C Series™ jaw crusher basic concepts 4 How to operate a C Series™ jaw crusher 6 C Series™ jaw crusher wear parts 8 One- or two-piece jaws 10 MX jaws 11 crusher

Capacities and performance characteristics of jaw crushers

trial jaw crushers was analyzed using the proposed equation in combination with that of Bond (1961) for calculating the energy requirement in size reduction. The equation for

Crushing Products Size and Shape -What to Expect

2016年2月26日Following the curve down to the 1.5″ line, we find that 43% of the primary crusher output may be expected to pass this screen opening; 57% will be retained, which means that we must provide secondary

Aggregate Crushers, for Rock, OreMinerals Gilson

Marcy ® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and production outputs. Models with 3,000lb per hour

sbm/sbm 12m3 jaw crusher size.md at main brblmd/sbm

Contribute to brblmd/sbm development by creating an account on GitHub.

® C Series™ jaw crushers Proven reliability and

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Jaw Crushers high quality and reliability from RETSCH

Jaw Crusher BB 500 Material feed size*: < 110 mm Final fineness*: 90% < 0.5 mm Throughput*: 500 kg/h Product details Maximum throughput Jaw Crusher BB 600 Material feed size*: < 350 x 170 mm Final fineness*: < 6 mm Throughput*: 3500 kg/h Product details *depending on feed material and instrument configuration/settings .

MC 110i EVO2 Mobile jaw crushers mpl Wirtgen Group

The jaw crusher MOBICAT MC 110 EVO2 is used for the precrushing of almost all natural rock and in recycling. Compact dimensions, efficient prescreening, simple operation via SPECTIVE as well as impressive production output characterize the efficient key player. Continuous Feed System (CFS) for optimal crusher feeding.

Metso ® C Series™ jaw parts

C Series™ jaw crusher basic concepts 4 How to operate a C Series™ jaw crusher 6 C Series™ jaw crusher wear parts 8 One- or two-piece jaws 10 MX jaws 11 crusher components. • Small feed size increases wear at the bot-tom of the cavity and may cause poor uti-lization of wear parts. 2. Check the feed arrangement

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Capacities and performance characteristics of jaw crushers

trial jaw crushers was analyzed using the proposed equation in combination with that of Bond (1961) for calculating the energy requirement in size reduction. The equation for capacity The volumeof material (V) that passes through the crusher bottom opening per stroke is given by: If the machine is run at low speeds, the movement of the

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Jaw crusher: feed diameter 0.1 to 1.5m; reduction ratio 5:1 to 10:1; capacity 1 to 300kg/s; Mohs hardness < 9 [reduction by compression]. Gyratory crusher: feed diameter 0.75 to 1.5m; reduction ratio 5:1 to 10:1, usually 8:1; capacity 140 to 1000 kg/s; Mohs hardness <9. More suitable for slabby feeds than jaw crusher. [reduction by

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日These types of compression crushers are best suited for heavy mining, quarried materials, sand and gravel, and recycling applications. They provide a reduction ratio of 3:1 to 6:1. Jaw Crushers

jaw crusher discharge size

2023年3月10日The size of the discharge depends on several factors, including the size of the opening at the bottom of the jaw, the angle of the jaw, and the movement of the jaw itself. Depending on the

Constmach 400 tph PRIMARY JAW CRUSHER YouTube

Constmach PRIMARY JAW CRUSHERFeeding Size: 1.250 x 1.000 mmCapacity: 400-450 tphconstmachcrusher info@constmachMobile, Whatsapp, Viber: +90 542...

Jaw Crushers Parker Plant

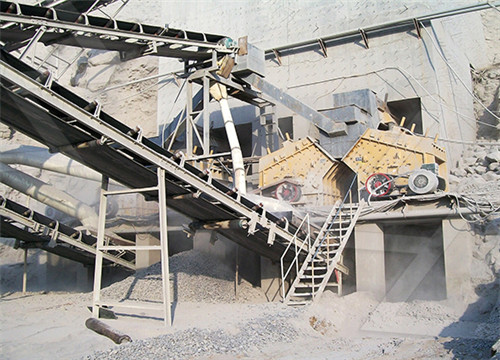

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single

Metso Crushers Data Sheets GlobalSpec

Metso Datasheets for Crushers. Industrial Crushers reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of ra. Crushers: Learn more.

Jaw Crusher Primary Crusher in MiningAggregate JXSC Mine

Product Introduction. JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of medium-hard materials to smaller physical size. Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume. Capacity: 1-1120TPH.

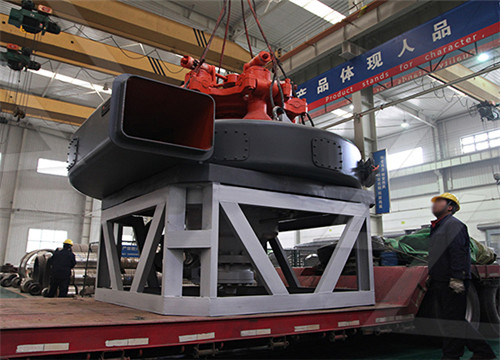

Industrial Solutions Gyratory crushers ThyssenKrupp

ing chamber below. Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter. Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Type Feed opening Mantle diameter

® C Series™ jaw crushers Proven reliability and

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Jaw Crushers high quality and reliability from RETSCH

Jaw Crusher BB 500 Material feed size*: < 110 mm Final fineness*: 90% < 0.5 mm Throughput*: 500 kg/h Product details Maximum throughput Jaw Crusher BB 600 Material feed size*: < 350 x 170 mm Final fineness*: < 6 mm Throughput*: 3500 kg/h Product details *depending on feed material and instrument configuration/settings .

MC 110i EVO2 Mobile jaw crushers mpl Wirtgen Group

The 12" touch panel is resistant to dust and always easy to read thanks to the light intensity and high contrast. It reacts to fingers, pen or gloves. Find out more SPECTIVE CONNECT Operator information App, unidirectional communication All relevant data at a glance > Dashboard > Camera live image > Reporting > Messages and troubleshooting aids

Metso ® C Series™ jaw parts

C Series™ jaw crusher basic concepts 4 How to operate a C Series™ jaw crusher 6 C Series™ jaw crusher wear parts 8 One- or two-piece jaws 10 MX jaws 11 crusher components. • Small feed size increases wear at the bot-tom of the cavity and may cause poor uti-lization of wear parts. 2. Check the feed arrangement

Industrial Solutions Jaw crushers ThyssenKrupp

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Capacities and performance characteristics of jaw crushers

trial jaw crushers was analyzed using the proposed equation in combination with that of Bond (1961) for calculating the energy requirement in size reduction. The equation for capacity The volumeof material (V) that passes through the crusher bottom opening per stroke is given by: If the machine is run at low speeds, the movement of the

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Jaw crusher: feed diameter 0.1 to 1.5m; reduction ratio 5:1 to 10:1; capacity 1 to 300kg/s; Mohs hardness < 9 [reduction by compression]. Gyratory crusher: feed diameter 0.75 to 1.5m; reduction ratio 5:1 to 10:1, usually 8:1; capacity 140 to 1000 kg/s; Mohs hardness <9. More suitable for slabby feeds than jaw crusher. [reduction by

Metso Crushers Data Sheets GlobalSpec

Metso Datasheets for Crushers. Industrial Crushers reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of ra. Crushers: Learn more.

jaw crusher discharge size

2023年3月10日The size of the discharge depends on several factors, including the size of the opening at the bottom of the jaw, the angle of the jaw, and the movement of the jaw itself. Depending on the

Constmach 400 tph PRIMARY JAW CRUSHER YouTube

Constmach PRIMARY JAW CRUSHERFeeding Size: 1.250 x 1.000 mmCapacity: 400-450 tphconstmachcrusher info@constmachMobile, Whatsapp, Viber: +90 542...

Jaw Crushers Parker Plant

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the up-thrust toggle RockSizer / StoneSizer model and down-thrust toggle RockSledger model. Size of Crusher

Characteristics and Comparison of Four Types of Jaw Crushers

2023年2月15日Model: PE jaw crusher 900*600: Capacity 150 t/h Feeding size approx.500mm Size of final grain 65-160mm Rotor speed 250-275rpm

Durable Medium Size Stone Jaw Crusher Machine Competitive Price

Rock jaw crusher is the primary crushing equipment in the crushing production line, it used to crush the large stone (300-1200mm) into medium size (100-200mm), the fine type jaw crusher can produce 0-40mm aggregate, the production capacity range of different model is from 1-1000 ton per hour.

Industrial Solutions Gyratory crushers ThyssenKrupp

ing chamber below. Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter. Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Type Feed opening Mantle diameter