Type Of Mills For Cement Manufacturing

11.6 Portland Cement Manufacturing US EPA

1971年8月17日11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of

Cement industry in the United States Wikipedia

OverviewUsesGeographyIndustry structureInputsEnvironmental EffectsSee alsoCitations

The cement industry in the United States produced 82.8 million tonnes (81,500,000 long tons; 91,300,000 short tons) of cement in 2015, worth US$9.8 billion, and was used to manufacture concrete worth about US$50 billion. The US was the world's third-largest producer of cement, after China and India. The US cement industry includes 99 cement mills in 34 states, plus two plants in Puerto Rico. The industry directly employed 10,000 workers in 2015. Ten percent of the ceme

Cement Mill Cement Grinding Machine AGICO Cement

AGICO offers EPC cement projects and different kinds of equipment needed for cement plant, such as a series of cement mills: cement ball mill, rod mill, cement vertical mill,

How Cement is Made Cement Manufacturing Process

预计阅读时间:5 分钟

Cement Manufacturing Process Phases Flow Chart

2012年8月30日Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of

Cement Finish Milling (Part 1: IntroductionHistory)

2019年12月2日The finish mill system in cement manufacturing is the second to last major stage in the process, where the feed material is reduced in size from as large as

Cement Manufacturing Process: 6 StepsTo Make Cement

2020年1月27日In this stage, there are two types of the raw mill to choose, the vertical cement mill uses the pressure leaked by cylinder to crush the passing materials. The cement ball mill use balls to grind the

Grinding Mills Common Types Mineral Processing

2016年11月7日In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging

Cement: Applications, Manufacturing Process, Types

Concrete is a combination of cement, sand or other fine aggregates, and a coarse aggregate ranging in size from 19 to 25 mm. People use concrete in a wide range of construction applications. Some applications of the

Cement industry in the United States Wikipedia

The cement industry in the United Statescement in 2015, worth US$9.8 billion, and was used to manufacture concrete worth about US$50 billion. The US was the world's third-largest producer of cement, after China and India. The US cement industry includes 99 cement mills in 34 states, plus two plants in Puerto Rico. The industry directly employed

What Equipment is Used for Cement Manufacturing? Prater

Cement Manufacturing Equipment. The abrasiveness of material and high temperatures involved in processing requires that cement manufacturing equipment be particularly robust. For North American cement manufacturing plants, vertical roller mills commonly handle the raw materials that will become cement, often with a throughput of 150-750

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement mill. AGICO Cement can supply cement mill according to your requirements.

Cement Mill for Sale Buy Cement Ball MillVertical Roller Mill

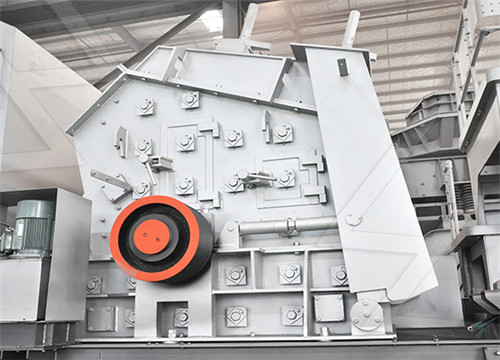

Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders. Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the

Cement Manufacturing Process Phases Flow Chart

2012年8月30日Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of

What are the parts of a mill in a cement plant?

2023年3月6日A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other materials into a fine powder that is used

BASIC CEMENT PLANT LAYOUT Process Cement

2020年7月4日The mills used for coal grinding and drying are either trumbling mills (tube mills) or roller mills. 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill. The output of a

Portland Cement Manufacturing Process In Cement Plant AGICO

The raw materials for Portland cement are mainly composed of three components: calcium oxide, silicon dioxide and alumina, which account for 60%, 20% and 10% of the total components respectively. The calcium oxide comes from limestone, while silica and alumina come from shale, clay and bauxite.

Cement: Applications, Manufacturing Process, Types

Concrete is a combination of cement, sand or other fine aggregates, and a coarse aggregate ranging in size from 19 to 25 mm. People use concrete in a wide range of construction applications. Some applications of the

The essentials of electrical systems in cement plants EEP

2022年12月29日In this technical article electrical systems in cement plant will be touched upon. All machines are driven by electric motors. Majority of the motors are 400- 440 volts. A selected few motors of higher ratings

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures

Cement Manufacturing Process: What is Cement made of.

Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method). 1. Limestones: These are sedimentary, calcium carbonate rocks (CaC0 3 ). Most commonly they contain a small amount of magnesium carbonate also.

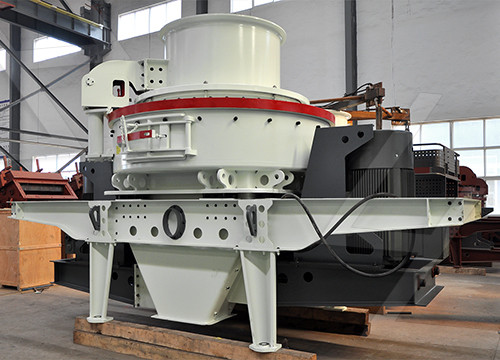

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.

Three Quick Tips For Manufacturing Of Cement Building

2017年10月3日The quality of cement is not so good as that of the one manufactured by the Wet process. this method has, therefore, become obsolete and the Wet process of manufacturing cement, described in details below, is widely used. 2. Wet process. (i) Mixing. The crushed raw materials in desired proportions are fed into ball mills (Fig. 5.1).

Cement industry in the United States Wikipedia

The cement industry in the United Statescement in 2015, worth US$9.8 billion, and was used to manufacture concrete worth about US$50 billion. The US was the world's third-largest producer of cement, after China and India. The US cement industry includes 99 cement mills in 34 states, plus two plants in Puerto Rico. The industry directly employed

What Equipment is Used for Cement Manufacturing? Prater

For North American cement manufacturing plants, vertical roller mills commonly handle the raw materials that will become cement, often with a throughput of 150-750 tons per hour. Bulk cement manufacturing equipment like rotary feeders help transfer raw materials at different points during production.

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement mill. AGICO Cement can supply cement mill according to your requirements.

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures

BASIC CEMENT PLANT LAYOUT Process Cement

2020年7月4日The mills used for coal grinding and drying are either trumbling mills (tube mills) or roller mills. 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill. The output of a

What are the parts of a mill in a cement plant?

2023年3月6日A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other materials into a fine powder that is used

Manufacturing the cement kiln Understanding

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two. The axis is inclined at a slight angle, the end with the

Cement: Applications, Manufacturing Process, Types

Concrete is a combination of cement, sand or other fine aggregates, and a coarse aggregate ranging in size from 19 to 25 mm. People use concrete in a wide range of construction applications. Some applications of the

Three Quick Tips For Manufacturing Of Cement

2017年10月3日The quality of cement is not so good as that of the one manufactured by the Wet process. this method has, therefore, become obsolete and the Wet process of manufacturing cement, described in

The essentials of electrical systems in cement plants EEP

2022年12月29日The most important raw materials for making cement are limestone, clay and marl. These are extracted from quarries by blasting or by ripping using heavy machinery. Wheel loaders and dumper trucks

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.

Cement Manufacturing Equipment for Sale AGICO Cement

AGICO cement machinery offers rotary kilns, cement mills, crushers, and many other cement manufacturing equipment for your cement business.

Cement Analysis IEA

Brimstone a US-based start-up has announced the development of a new cement-making process sourcing lime from calcium silicate rocks instead of limestone, which would avoid the generation of process emissions in the calcination process and produce a magnesium-based waste product that can even absorb emissions from fuel combustion.

CO2 Emissions Profile of the U.S. Cement Industry US EPA

type of cement is determined based upon the type and quantity of additives added. Cooled clinker can be mixed with a small quantity of gypsum to produce Portland cement or can be mixed with a greater quantity of lime to produce masonry cement. ENERGY USE Total energy consumption in the U.S. cement industry exhibited a decline between 1970 and the