Over Flow Rolling Bearing Mine Industrial Ball Mill

Ball Mill-MECRU

3.According to the unloading method, it can be divided into grid type and overflow type. Mouse drag product 360°rotation Product Advantages The rolling bearing is used

Tapered roller bearings features, benefits, applications

With a wide range of designs to choose from, SKF tapered roller bearings are also customizable to match your specific speed, load, contamination, temperature or vibration

进一步探索

SKF Tapered Roller Bearings Catalogue Nodes BearingSKF bearings cross reference SKF bearing interchange根据热度为您推荐•反馈

Grinding mills for mining and minerals processing

Metso Outotec Select™ horizontal grinding mills are a pre-engineered range of class-leading horizontal grinding mills, designed from industry leading experience and

Ball Mills Industry Grinder for Mineral Processing JXSC

2018年1月30日Ball mill, also known as ball grinding machine, is a well-known ore grinding machine, is widely used in mining, construction, aggregate application. JXSC

Industrial Ball Mills: Steel Ball Mills and Lined Ball Mills

Lifting baffles are supplied to prevent the outer layer of media to simply roll around the cylinder. Our combined experience in ball mill design and process equipment

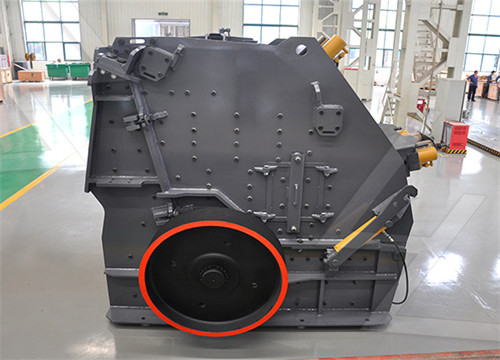

over flow rolling bearing mine industry ball mill

Buy over flow rolling bearing mine industry ball mill from Machine Business Opportunities, over flow rolling bearing mine industry ball mill specifications: ball mill

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日Steel-Head Ball-Rod Mills are available in any one of five different types of discharge: Overflow, perforated overflow, return spiral, grate, and peripheral. To best

Ball Mill MaintenanceInstallation Procedure

2016年10月19日We recommend a mixture of 1:2:3 for ball mill and rod mill foundations. The proper water to sand ratio should be carefully regulated since excess water

Rolling bearings SKF

Rolling bearings support and guide rotating or oscillating machine elements such as shafts, axles or wheels and transfer loads between machine components. They provide

Ball Mills Mt Baker Mining and Metals

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best

Addition of pebbles to a ball-mill to improve grinding efficiency

2018年11月1日Overflow ball-mills are often used and a mixture of ball sizes is used to top up the ball charge at regular intervals, e.g. the K Mt Charlotte circuit in Australia used a mixture of 70 mm and 60 mm balls (Dupont, 2006), the Batu Hijau concentrator in Indonesia used a mixture of 65 mm and 80 mm balls (Burger et al., 2006) and the

v117n1a11 Performance optimization of an industrial ball

Motor power 700 KW Bearing Spherical roller bearings Mill power (max.) 605 KW Bearing Spherical roller bearings Mill speed (variable) 17.8 r/min (max): 74.6% Ncr Trunion (both ends) Type FAG 239/850K.MB.C3 14.3 r/min–60% Ncr Hydraulic sleeve FAG H564124 12.7 rpm (min)–53% Ncr Grinding media size 70 mm (max.) Mill lining Wear resistant

Tapered roller bearings features, benefits, applications SKF

With a wide range of designs to choose from, SKF tapered roller bearings are also customizable to match your specific speed, load, contamination, temperature or vibration conditions. SKF Tapered roller bearings feature a cup and cone assembly. The cup is comprised of the outer ring and the cone assembly consists of inner ring, rollers, and cage.

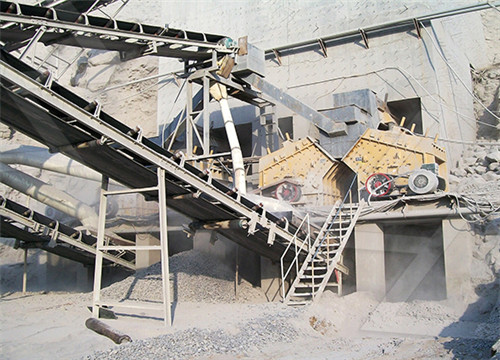

Grinding mills for mining and minerals processing Metso Outotec

Metso Outotec Select™ horizontal grinding mills are a pre-engineered range of class-leading horizontal grinding mills, designed from industry leading experience and expertise. The pre-engineered package eliminates time and costs usually spent in the engineering and selection stages. Learn more about the Select™ horizontal grinding mills >

Industrial Ball Mills: Steel Ball Mills and Lined Ball Mills Orbis

Lifting baffles are supplied to prevent the outer layer of media to simply roll around the cylinder. Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Ball Mill Drive Options

over flow rolling bearing mine industry ball mill

Buy over flow rolling bearing mine industry ball mill from Machine Business Opportunities, over flow rolling bearing mine industry ball mill specifications: ball mill features:, 1.feeding size: less than 25mm, 2.capacity:0.65-130t/h, 3.outputs: powder and granule, 4.application: grind

Ball Mill MaintenanceInstallation Procedure

2016年10月19日On Mill Installation and Maintenance. Before starting the erection of the mill, adequate handling facilities should be provided or made available, bearing in mind the weights and proportions of the various parts and sub-assemblies. This information can be ascertained from the drawings and shipping s.

Circulating Load Calculation Formula Mineral Processing

2015年2月21日Circulating Load Calculation Formula Here is a formula that allows you to calculate the circulating load ratio around a ball mill and hydrocylone as part of a grinding circuit. For example your ball mill is in closed circuit with a set of cyclones. The grinding mill receives crushed ore feed.

Grinding mill parts Metso Outotec

Grinding mill main bearings Material: fabricated steel (welded) Type: hydrostatic or hydrodynamic (sleeve/pad), fixed or floating Design standard: Metso FEA Upgrade options: bearing insert (bronze, babbitt), seals, temperature monitoring systems, lubrication unit Grinding mill trunnions Material: cast ductile iron Design standard: Metso FEA

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill Operator

Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns. The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 microns.

Hot-sale Industrial Ball Mills OverflowGrate Ball Mill

In a word, an overflow ball mill is a pulverizing machine with convenient maintenance and fine grinding size. It has a competitive price but the grinding efficiency is lower than other ball mills. The above is a brief introduction of two industrial ball mills: grate ball mill and overflow ball mill.

Bearing type and arrangement SKF

Bearing execution. STEP 8. Sealing, mounting and dismounting. Each bearing type has characteristic properties that make it more or less suitable for use in a given application. Matrix 1 gives an overview of the main bearing types (including their major features and design variants) and their degree of suitability for certain aspects of use

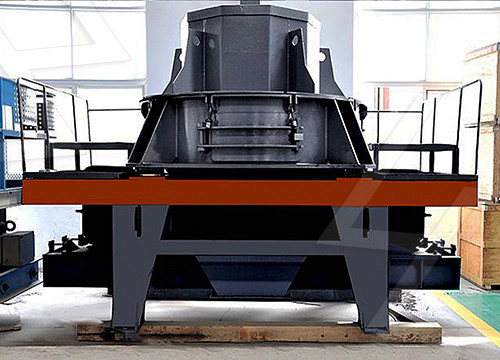

Types of Ball Mill Machine Meet Your Industrial Grinding

As a professional ball mill machine manufacturer and supplier, we can provide types of ball mill according to customer’s requirements. According to production mode: dry ball mill (without adding water) and wet ball mill. According to the process used: dryer mill, superfine ball mill, open-circuit mill, closed-circuit grinding mill, etc.

Ball Mills Mt Baker Mining and Metals

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best

Addition of pebbles to a ball-mill to improve grinding efficiency

2018年11月1日Overflow ball-mills are often used and a mixture of ball sizes is used to top up the ball charge at regular intervals, e.g. the K Mt Charlotte circuit in Australia used a mixture of 70 mm and 60 mm balls (Dupont, 2006), the Batu Hijau concentrator in Indonesia used a mixture of 65 mm and 80 mm balls (Burger et al., 2006) and the

v117n1a11 Performance optimization of an industrial ball

Motor power 700 KW Bearing Spherical roller bearings Mill power (max.) 605 KW Bearing Spherical roller bearings Mill speed (variable) 17.8 r/min (max): 74.6% Ncr Trunion (both ends) Type FAG 239/850K.MB.C3 14.3 r/min–60% Ncr Hydraulic sleeve FAG H564124 12.7 rpm (min)–53% Ncr Grinding media size 70 mm (max.) Mill lining Wear resistant

Tapered roller bearings features, benefits, applications SKF

With a wide range of designs to choose from, SKF tapered roller bearings are also customizable to match your specific speed, load, contamination, temperature or vibration conditions. SKF Tapered roller bearings feature a cup and cone assembly. The cup is comprised of the outer ring and the cone assembly consists of inner ring, rollers, and cage.

over flow rolling bearing mine industry ball mill

Buy over flow rolling bearing mine industry ball mill from Machine Business Opportunities, over flow rolling bearing mine industry ball mill specifications: ball mill features:, 1.feeding size: less than 25mm, 2.capacity:0.65-130t/h, 3.outputs: powder and granule, 4.application: grind

Mill Bearing StrengthGrinding Mill Design

2017年5月15日Fig. 1 shows that there are four basic components The shell, the heads, the ring gear and the trunnions. The heads are usually bolted to the shell. The trunnions are secured to the heads by bolts or made integrally with the head. The ring gear is usually bolted to one head section. The forces acting on the mill are both static and dynamic.

Ball Mill MaintenanceInstallation Procedure

2016年10月19日On Mill Installation and Maintenance. Before starting the erection of the mill, adequate handling facilities should be provided or made available, bearing in mind the weights and proportions of the various parts and sub-assemblies. This information can be ascertained from the drawings and shipping s.

Types Of Rolling Process In Manufacturing Industry

A) Thread/Gear Rolling. The thread/ gear rolling is a cold-forming type of rolling process used to cut gear or threads on a cylindrical blank. In this process, the threaded dies are fitted on cylindrical rollers of the rolling machine. The cylindrical blank presses the threaded roller and roll against the faces, which displace the material and

Bearings for Rolling mill Rolls IspatGuru

2017年5月17日The bearings of the rolls are to provide high performance so that the mill downtime can be reduced. Roll bearings are required to withstand heavy loads and high speed rotations as well as severe operating environments.

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill Operator

Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns. The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 microns.

Grinding mill parts Metso Outotec

Grinding mill main bearings Material: fabricated steel (welded) Type: hydrostatic or hydrodynamic (sleeve/pad), fixed or floating Design standard: Metso FEA Upgrade options: bearing insert (bronze, babbitt), seals, temperature monitoring systems, lubrication unit Grinding mill trunnions Material: cast ductile iron Design standard: Metso FEA

Bearing type and arrangement SKF

STEP 1 Performance requirements and operating conditions STEP 2 Bearing type and arrangement STEP 3 Bearing size STEP 4 Lubrication STEP 5 Operating temperature and speed STEP 6 Bearing interfaces STEP 7 Bearing execution STEP 8 Sealing, mounting and dismounting

Types of Ball Mill Machine Meet Your Industrial Grinding

As a professional ball mill machine manufacturer and supplier, we can provide types of ball mill according to customer’s requirements. According to production mode: dry ball mill (without adding water) and wet ball mill. According to the process used: dryer mill, superfine ball mill, open-circuit mill, closed-circuit grinding mill, etc.